Welding gun offset determining method for arc-welding remanufacturing of plate-like titanium alloy wear-out part

A technology to determine the method and offset, applied in the direction of manufacturing tools, arc welding equipment, electrode characteristics, etc., can solve the problems of difficult process parameters, narrow application range, cumbersome calculations, etc., to achieve strong controllability, strong applicability, and reduce The effect of heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

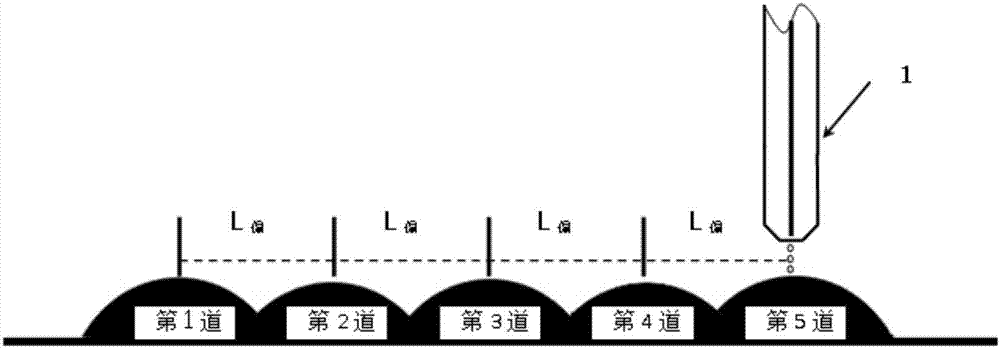

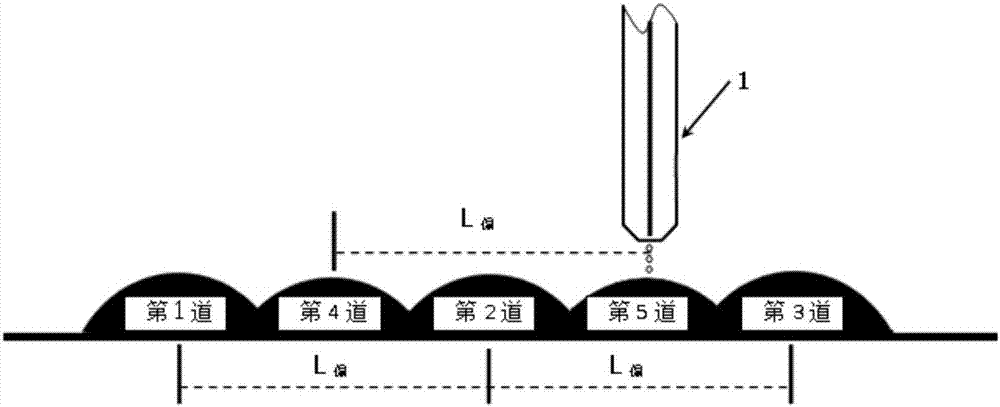

[0033] Use the inventive method for determining the offset of the welding torch for the arc welding remanufacture of plate titanium alloy wear parts to repair the wear of plate titanium alloy parts (wear area: 20mm×30mm, maximum depth 1.3mm), and the diameter of the welding wire is 0.8mm, and the sequential stacking method is used for remanufacturing and forming repair, P 堆积 Use 4mm 2 At this time, the selected process parameters are wire feeding speed 6.5m / min, welding speed 13.6mm / s, welding torch offset of the second pass (relative to the first weld seam) L 偏 The value calculation method is: (0.95~1.05)(2.1+0.007P 堆积 2 )mm, the value range is 2.1mm~2.32mm, choose 2.1mm, and weld the worn area in turn.

[0034] Compared with the traditional welding repair, the welding torch offset can be directly determined by the accumulation rate, no preliminary test is required, the heat input is low, the welding repair has good formability, smooth surface, less fish scales, dense stru...

Embodiment 2

[0036] Use the inventive method for determining the offset of the welding torch for arc welding remanufacturing of plate titanium alloy wear parts to repair the wear of plate titanium alloy parts (wear area: 30mm×40mm, maximum depth 1.1mm), and the diameter of the welding wire 1.2mm, using sequential stacking method for remanufacturing and forming repair, P 堆积 Use 30mm 2 At this time, the selected process parameters are wire feeding speed 10.0m / min, welding speed 6.28mm / s, welding torch offset of the second pass (relative to the first weld seam) L 偏 The value calculation method is: (0.95~1.05)(2.1+0.007P 堆积 2 )mm, the value range is 7.98mm~8.82mm, choose 8.82mm, and perform welding repair on the worn area in turn.

[0037] Compared with the traditional welding repair, the method of determining the offset of the welding torch is fast, simple and convenient, with low heat input, no flow phenomenon, small thermal influence, and good flatness after repair of the worn surface. W...

Embodiment 3

[0039] Use the inventive method for determining the offset of the welding torch for arc welding remanufacturing of plate titanium alloy wear parts to repair the wear of plate titanium alloy parts (wear area: 50mm×60mm, maximum depth 1.2mm), and the diameter of the welding wire 1.0mm, using sequential stacking method for remanufacturing and forming repair, P 堆积 Choose 16mm 2 At this time, the selected process parameters are wire feeding speed 10.0m / min, welding speed 8.18mm / s, welding torch offset of the second pass (relative to the first weld seam) L 偏 The value calculation method is: (0.95~1.05)(2.1+0.007P 堆积 2 )mm, the value range is 3.70mm~4.09mm, choose 3.85mm, and weld the worn area in turn.

[0040] Compared with traditional welding repair, there is no need for trial welding, and no need to measure weld reinforcement and weld width. Within the determined welding parameter range, the welding torch offset can be quickly determined according to the accumulation rate, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com