High-temperature-resistant and cracking-resistant cable material and preparing method thereof

An anti-cracking, cable material technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problem of not meeting the requirements of high temperature resistance of 150 °C, the anti-cracking performance can not meet the needs of use, affecting the application and promotion, etc. Achieve the effects of good environmental stress crack resistance, good processing fluidity and strong practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

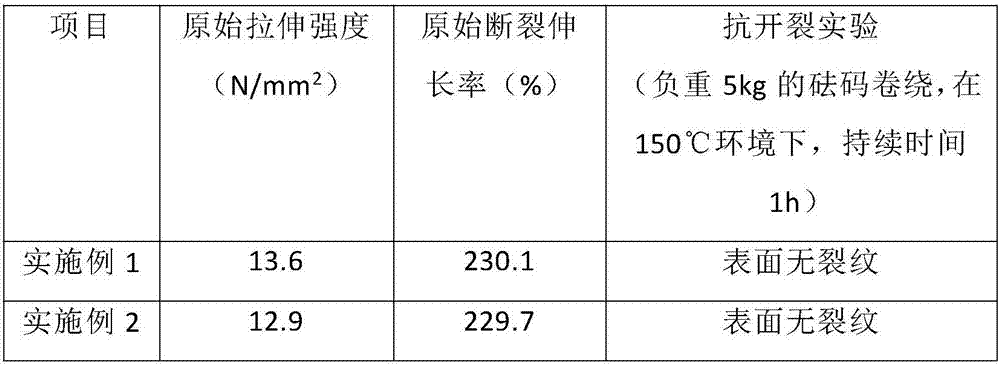

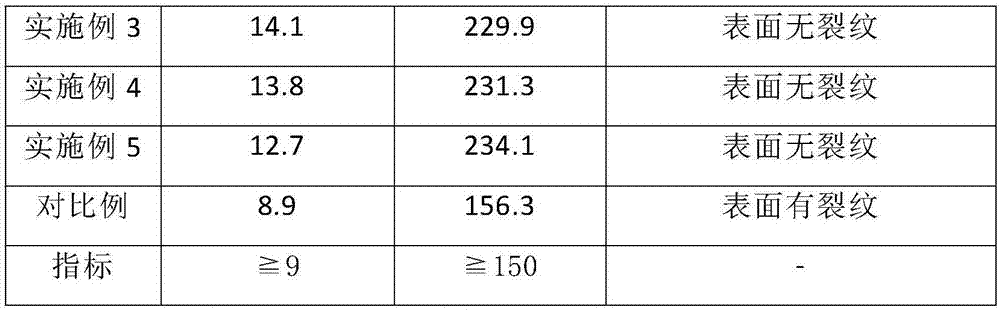

Examples

Embodiment 1

[0023] A high-temperature-resistant and crack-resistant cable material provided in this embodiment includes the following raw materials in parts by weight: 64 parts of high-density polyethylene, hydrogenated styrene-isoprene-benzene 17 parts of ethylene block copolymer, 7 parts of composite fiber material, 2 parts of glycerol stearate, 5 parts of color masterbatch, 1 part of lubricant, 2.8 parts of coupling agent, 1.3 parts of stabilizer, and 2.9 parts of plasticizer.

[0024] Wherein, the composite fiber material component includes alumina fiber, mullite fiber, silicon carbide fiber, silica airgel, alumina airgel.

[0025] Wherein, the composite fiber material is made by mixing alumina fibers, mullite fibers, silicon carbide fibers, silica aerogels, and alumina aerogels, followed by supercritical drying.

[0026] Wherein, the lubricant is a silicone lubricant.

[0027] Wherein, the stabilizer is tribasic lead sulfate, dibasic lead phosphite or lead-barium composite stabilize...

Embodiment 2

[0033] This embodiment provides a high-temperature-resistant and crack-resistant cable material. The high-temperature-resistant and crack-resistant cable material includes the following raw materials in parts by weight: 52 parts of high-density polyethylene, hydrogenated styrene-isoprene-benzene 32 parts of ethylene block copolymer, 1 part of composite fiber material, 5 parts of glycerin stearate, 2 parts of color masterbatch, 4 parts of lubricant, 0.6 part of coupling agent, 3.4 parts of stabilizer, and 1.6 parts of plasticizer.

[0034] Wherein, the composite fiber material component includes alumina fiber, mullite fiber, silicon carbide fiber, silica airgel, alumina airgel.

[0035] Wherein, the composite fiber material is made by mixing alumina fibers, mullite fibers, silicon carbide fibers, silica aerogels, and alumina aerogels, followed by supercritical drying.

[0036] Wherein, the lubricant is a silicone lubricant.

[0037] Wherein, the stabilizer is tribasic lead sul...

Embodiment 3

[0043] A high-temperature-resistant and crack-resistant cable material provided in this embodiment includes the following raw materials in parts by weight: 62 parts of high-density polyethylene, hydrogenated styrene-isoprene-benzene 17 parts of ethylene block copolymer, 4 parts of composite fiber material, 2 parts of glycerol stearate, 4 parts of color masterbatch, 1 part of lubricant, 2.2 parts of coupling agent, 1.3 parts of stabilizer, and 2.2 parts of plasticizer.

[0044] Wherein, the composite fiber material component includes alumina fiber, mullite fiber, silicon carbide fiber, silica airgel, alumina airgel.

[0045] Wherein, the composite fiber material is made by mixing alumina fibers, mullite fibers, silicon carbide fibers, silica aerogels, and alumina aerogels, followed by supercritical drying.

[0046] Wherein, the lubricant is a silicone lubricant.

[0047] Wherein, the stabilizer is tribasic lead sulfate, dibasic lead phosphite or lead-barium composite stabilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com