Liquid for strengthening corrosion resistance of waterborne coating pigment for wheel hub spraying and preparation method of liquid

A water-based paint, corrosion-resistant technology, applied in anti-corrosion paint, conductive paint, starch paint, etc., can solve the problems of poor pigment dispersion, achieve good shear resistance, enhance pigment dispersion, and good dispersion stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: the liquid that enhances the corrosion resistance of water-based paint pigments used for wheel hub spraying is prepared from the following components:

[0032] 60 parts of cotton linters, 1 part of preservative, 1 part of defoaming and decontaminating mixed solvent, 1 part of antifungal fungicide, 5 parts of viscosity reducer, 5 parts of surface modifier, 5 parts of metal ion chelating agent, corrosion inhibitor 2 parts, 50 parts of water, 12 parts of corn starch, 8 parts of acrylic acid-allyl polyoxyethylene ether-sodium styrene sulfonate terpolymer, 26 parts of naphthalene sulfonic acid-styrene-maleic acid terpolymer , 3 parts of chloroacetic acid, 2 parts of polyacrylamide.

[0033] A method for preparing a liquid for enhancing the corrosion resistance of water-based paint pigments used for wheel hub spraying, the preparation method comprising the following steps:

[0034] Mix acrylic acid-allyl polyoxyethylene ether-sodium styrene sulfonate terpolymer...

Embodiment 2

[0053] Embodiment 2: the liquid that strengthens the corrosion resistance of the water-based paint pigment used for wheel hub spraying: it is prepared from the following components:

[0054] 80 parts of cotton linters, 5 parts of preservatives, 6 parts of defoaming and decontaminating mixed solvents, 4 parts of antifungal and fungicides, 25 parts of viscosity reducers, 15 parts of surface modifiers, 25 parts of metal ion chelating agents, corrosion inhibitors 12 parts, 58 parts of water, 23 parts of corn starch, 16 parts of acrylic acid-allyl polyoxyethylene ether-sodium styrene sulfonate terpolymer, 52 parts of naphthalene sulfonic acid-styrene-maleic acid terpolymer , 6 parts of chloroacetic acid, 7 parts of polyacrylamide.

[0055] A method for preparing a liquid for enhancing the corrosion resistance of water-based paint pigments used for wheel hub spraying, the preparation method comprising the following steps:

[0056] Mix acrylic acid-allyl polyoxyethylene ether-sodium...

PUM

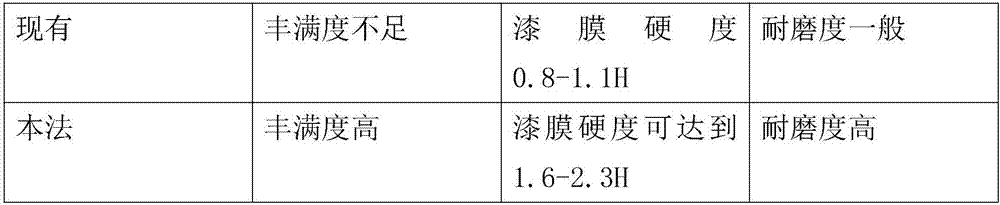

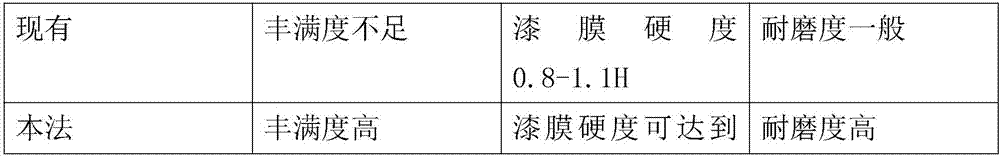

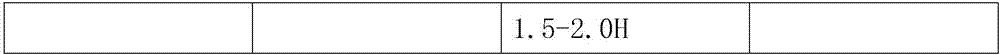

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com