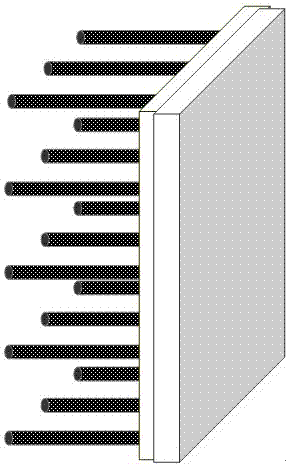

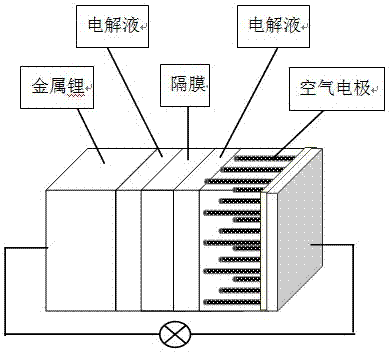

Preparation method for nitrogen-doped carbon nanotube array/carbon fiber material air electrode

A carbon fiber material, nanotube array technology, applied in the direction of fuel cell type half-cell and primary battery type half-cell, etc., can solve the problems of low catalytic activity, high chemical inertness, high contact resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

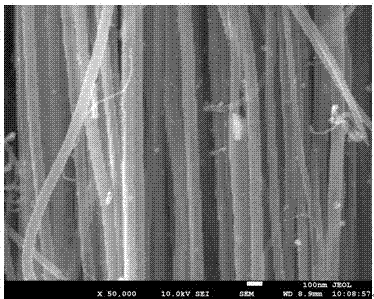

Method used

Image

Examples

Embodiment 1

[0054] The specific implementation of a nitrogen-doped carbon nanotube array / carbon fiber material air electrode preparation method is carried out according to the following steps:

[0055] (1) Pretreatment of carbon paper

[0056] 1 g of conductive carbon black and 0.036 g of ammonium persulfate were added to 200 mL of deionized water, mechanically stirred in a constant temperature water bath at 30 °C for 20 h, filtered with suction, washed, and then vacuum-dried at 80 °C for 24 h to obtain oxidized conductive carbon black. Carbon black; Weigh the above-mentioned 0.08 g oxidized conductive carbon black and 6 g ferric nitrate and add them to 15 g of 30% silica sol solution respectively, and stir at room temperature for 18 h to obtain uniform black suspension ink; the conductive carbon paper Immerse in 100 mL of isopropanol solution, ultrasonically clean at 100 Hz for 20 min to remove impurities on the surface, take it out and dry it; then use a scraper to gently scrape off the...

Embodiment 2

[0062] (1) Pretreatment of carbon cloth

[0063]Add 1 g of conductive graphite and 0.072 g of ammonium nitrate to 150 mL of deionized water respectively, mechanically stir in a constant temperature water bath at 25°C for 10 h, filter with suction, wash, and then vacuum-dry at 60°C for 36 h to obtain oxidized conductive graphite; Weigh 0.1 g of the above oxidized conductive graphite and 3 g of cobalt carbonate and add them to 10 g of 30% silica sol solution, stir at room temperature for 15 h to obtain a uniform black suspension ink; immerse the conductive carbon cloth in 50 mL In methanol solution, ultrasonically clean at 100 Hz for 30 minutes to remove impurities on the surface, take it out and dry it; then gently scrape off the burrs on the surface of the carbon cloth with a scraper, and drop a small amount of the above ink onto the carbon cloth with a disposable dropper , the glass rod is rolled and spread evenly, and finally the excess ink on the surface is gently scraped o...

Embodiment 3

[0069] (1) Pretreatment of carbon felt

[0070] 1 g of conductive activated carbon and 0.018 g of ammonium chlorate were added to 220 mL of deionized water, mechanically stirred in a constant temperature water bath at 40 °C for 40 h, suction filtered, washed, and then vacuum-dried at 90 °C for 24 h to obtain oxidized conductive activated carbon ; The above-mentioned 0.3g oxidized conductive activated carbon and 7 g nickel phosphate were added to 20 g of 30% silica sol solution respectively, and stirred at room temperature for 30 h to obtain uniform black suspension ink; the conductive carbon felt was immersed in 300 mL of ethanol solution, ultrasonically cleaned at 100 Hz for 40 min to remove impurities on the surface, took it out and dried it; then gently scraped off the burrs on the surface of the carbon felt with a scraper, and dropped a small amount of the above ink onto the carbon felt with a disposable dropper. On the felt, the glass rod is rolled and spread evenly, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com