Magnetic fullerene nano-material and application thereof to solid-phase extraction

A nanomaterial, fullerene technology, applied in other chemical processes, color/spectral characteristic measurement, alkali metal oxide/hydroxide, etc., can solve the problem of not being able to maintain magnetism, and achieve easy elution and strong adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

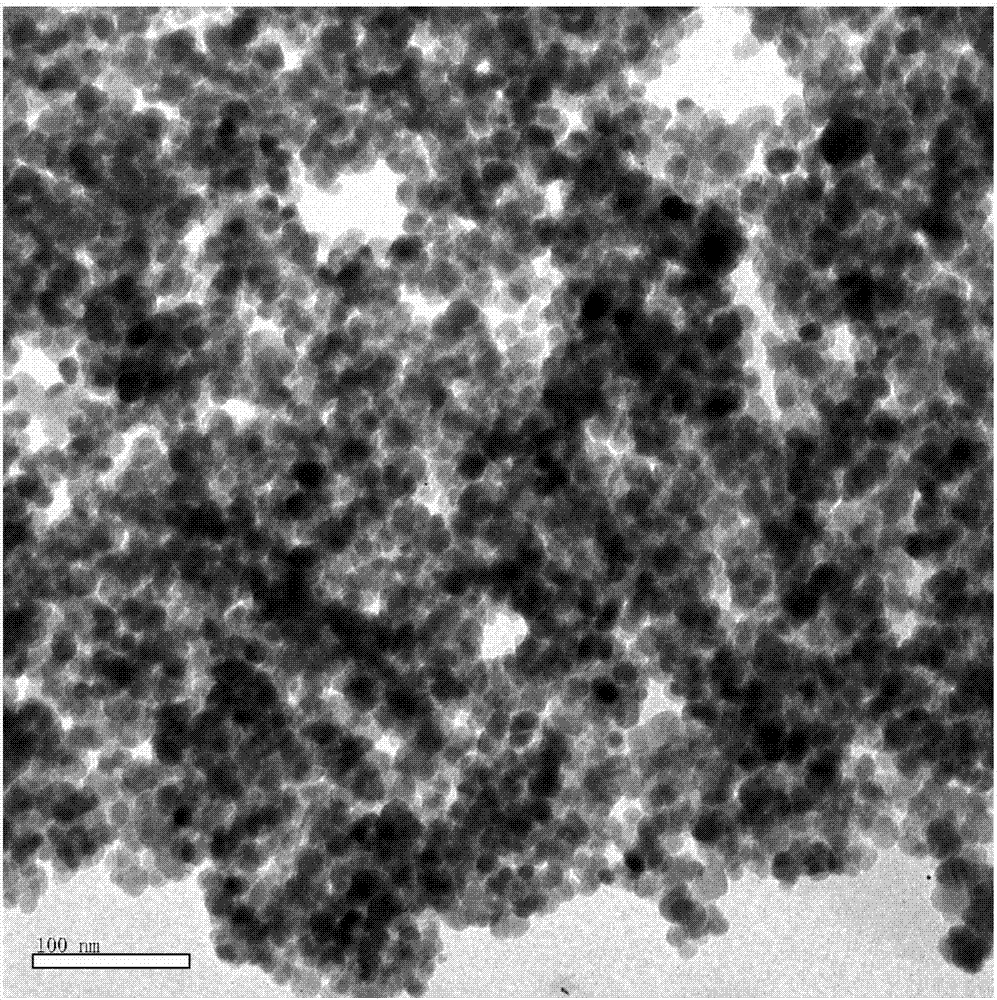

[0024] Take 200mL distilled water, add 0.2mmol C 60 Fullerene, 0.4mmol ferrous sulfate heptahydrate, 0.8mmol anhydrous ferric chloride, after feeding nitrogen and stirring for 15 minutes, heating to reflux temperature, keeping reflux for 20-30 minutes, cooling to 85-90°C, maintaining the temperature (85-90°C), add ammonia water (6mL) dropwise, continue to stir for 1-1.5h, the reaction solution is in a black turbid state, it naturally drops to room temperature, and after standing for 0.5h, it is adsorbed and separated by a magnet to obtain a black solid; After washing with distilled water for 3-5 times, vacuum-dry at 60°C for 12 hours to obtain a black solid powder, which is Magnetic C 60 Fullerene nanomaterials (abbreviated as C 60 -Fe 3 o 4 , figure 1 , hereinafter referred to as product A); the distilled water used in the present embodiment is the distilled water after ultrasonic.

Embodiment 2

[0026] Take 100mL distilled water, add 0.1mmol C 60Fullerene, 0.2mmol of ferrous sulfate heptahydrate, 0.4mmol of anhydrous ferric chloride, after argon gas stirring for 20 minutes, heating to reflux temperature, keeping reflux for 20-30 minutes, cooling to 85-90°C, maintaining Add ammonia water (5mL) dropwise at this temperature (85-90°C), continue to stir and react for 1-1.5h, the reaction solution is in a black and turbid state, it naturally drops to room temperature, and after standing for 0.5h, it is adsorbed and separated by a magnet to obtain a black solid; After washing with distilled water for 3-5 times, vacuum-dry at 60°C for 24 hours to obtain a black solid powder, which is Magnetic C 60 Fullerene nanomaterials (abbreviated as C 60 -Fe 3 o 4 , SEM image with figure 1 Consistent, hereinafter referred to as product B); The distilled water used in the present embodiment is the distilled water after ultrasonic.

Embodiment 3

[0028] Take 200mL distilled water, add 0.2mmol graphene, 0.4mmol ferrous sulfate heptahydrate, 0.8mmol anhydrous ferric chloride, stir for 15 minutes with nitrogen gas, heat to reflux temperature, keep reflux for 20-30 minutes, then cool down to 85 -90°C, maintain the temperature (85-90°C) and add ammonia water (6mL) dropwise, continue to stir for 1-1.5h, the reaction solution is black and turbid, naturally lowered to room temperature, after standing for 0.5h, use a magnet to separate , to obtain a black solid; after washing 3-5 times with distilled water, obtain a black solid powder at 60°C for 12h in vacuum, which is a magnetic graphene material (hereinafter referred to as product C); the distilled water used in the present embodiment is after ultrasonic distilled water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com