Method for biochemically treating electric plating waste water on basis of multi-dimensional strong oxidization and circulation

A technology for biochemical treatment and electroplating wastewater, applied in chemical instruments and methods, multi-stage water treatment, biological water/sewage treatment, etc. The effect of reducing mud production and pollutant content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

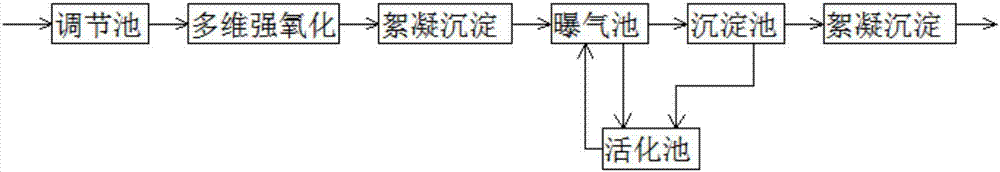

[0016] The invention relates to a method for treating electroplating wastewater based on multidimensional strong oxidation and cyclic biochemical treatment. The multidimensional strong oxidative process in the method includes at least one of electrocatalysis, electroflocculation and electro-Fenton, and the cyclic biochemical process is processed through the metabolism of microorganisms Pollutants in wastewater, based on the above two points, when treating garbage permeate, sequentially carry out regulating tank treatment, multi-dimensional strong oxidation treatment, cyclic biochemical treatment and advanced treatment, and finally realize the harmless treatment of electroplating wastewater. The specific operation process is through specific Examples are described.

[0017] Specific examples, such as figure 1 As shown, the method for the treatment of electroplating wastewater may further comprise the steps:

[0018] A. Put the electroplating wastewater into the regulating pool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com