High-heat-insulation nano ceramic powder, and preparation method and application thereof

A technology of nano-ceramic powder and ceramic powder, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of easy deterioration, low cost investment, failure of semiconductor nano-oxides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 10 kg of tetraethyl titanate, 20 kg of methanol, and 20 kg of ethylenediamine, stir until a clear and transparent solution is obtained, and obtain a solid substance by distillation under reduced pressure. The liquid obtained by distillation can be recycled.

[0030] Put the obtained solid precursor into an annealing furnace, pass high-purity argon as a protective atmosphere, slowly increase the temperature at a rate of 2-4°C per minute, keep it at 800°C for 120 minutes, and then cool it. Black nano titanium nitride powder can be obtained.

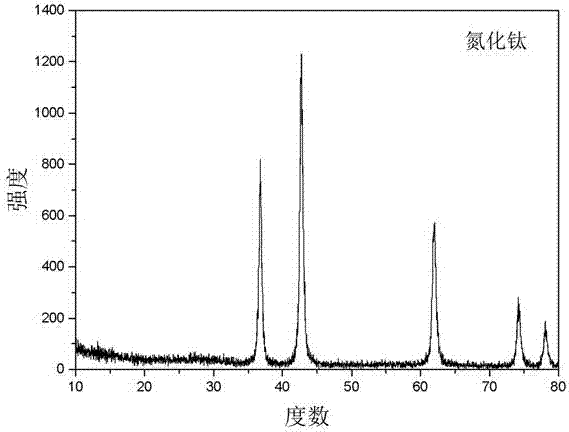

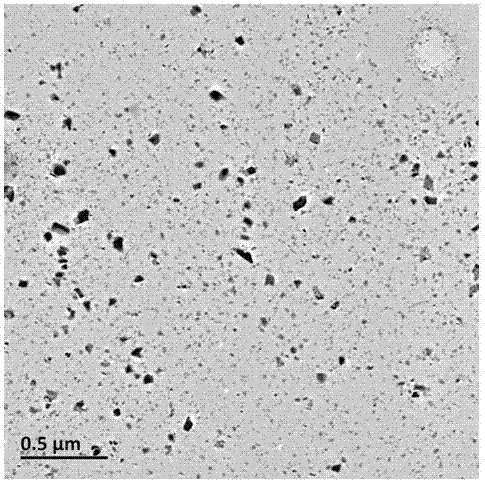

[0031] The black nano titanium nitride was characterized by X-ray diffractometer and transmission electron microscope.

[0032] figure 1 The crystal structure map of titanium nitride nanopowder, figure 2 Transmittance spectra of titanium nitride nanoparticle.

Embodiment 2

[0034] Weigh 10 kg tetraethyl titanate, 20 kg ethanol, and 20 kg propylenediamine, stir until a clear and transparent solution is obtained, and obtain a solid substance by vacuum distillation. The liquid obtained by distillation can be recycled.

[0035] Put the obtained solid precursor into an annealing furnace, pass high-purity argon as a protective atmosphere, slowly increase the temperature at a rate of 2-4°C per minute, keep it at 800°C for 120 minutes, and then cool it. Black nano titanium nitride powder can be obtained.

[0036] The black nano titanium nitride was characterized by X-ray diffractometer and transmission electron microscope.

[0037] Obtained XRD and TEM figures are similar to Example 1.

Embodiment 3

[0039] Weigh 10 kg tetrabutyl titanate, 20 kg isopropanol, and 20 kg diethanolamine, stir until a clear and transparent solution is obtained, and obtain a solid substance by vacuum distillation. The liquid obtained by distillation can be recycled.

[0040] Put the obtained solid precursor into an annealing furnace, pass high-purity argon as a protective atmosphere, slowly increase the temperature at a rate of 2-4°C per minute, keep it at about 900°C for 120 minutes, and then cool it. Black nano titanium nitride powder can be obtained.

[0041] The black nano titanium nitride was characterized by X-ray diffractometer and transmission electron microscope.

[0042] Obtained XRD and TEM figures are similar to Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap