Molybdenum disulfide quantum dot preparation method

A technology of molybdenum disulfide and quantum dots, applied in the direction of molybdenum sulfide, etc., can solve the problems of large-scale and high-efficiency preparation of quantum dots, long time-consuming, low yield, etc., to achieve weakening of the van der Waals force between layers, short time-consuming, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

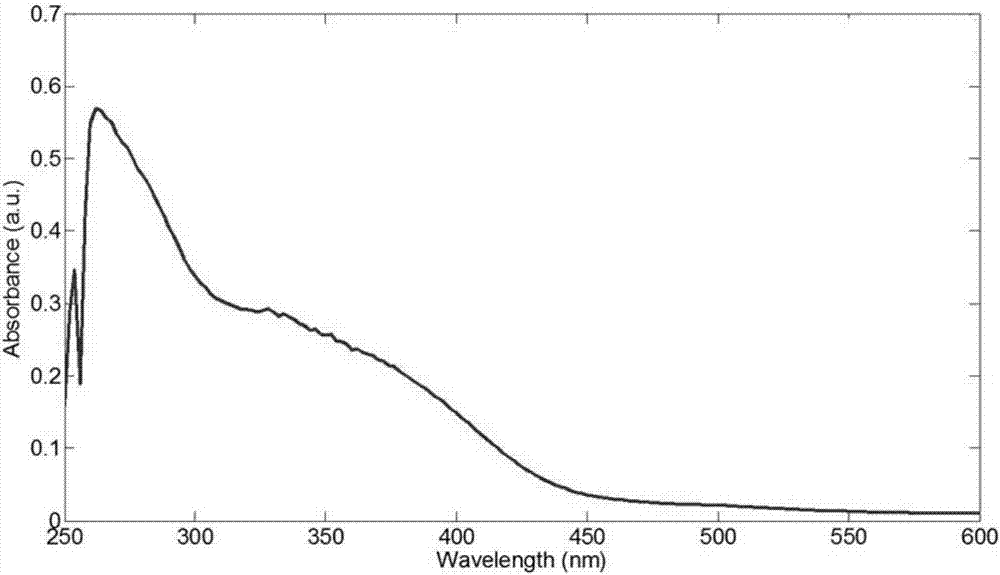

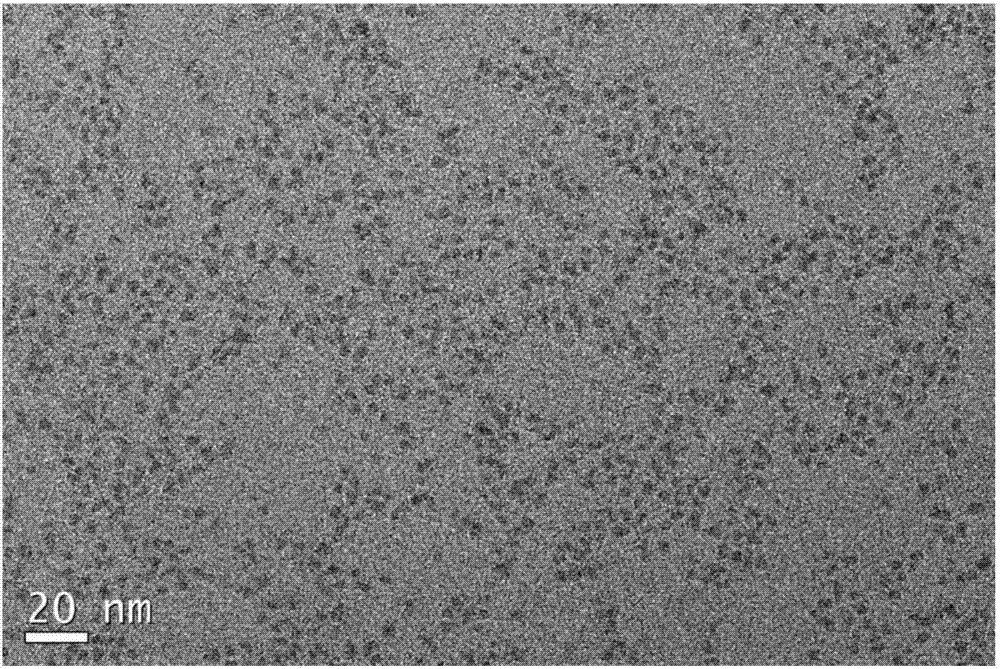

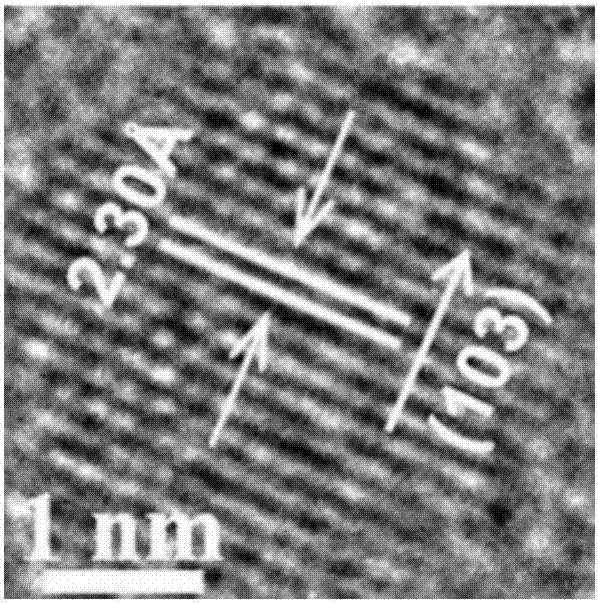

[0038] A preparation method of molybdenum disulfide quantum dots, comprising the steps of:

[0039] (1) Put 250 mg of molybdenum disulfide powder with a particle size of less than 2 μm in an agate mortar, add 1 g of 1-butyl-3-methylimidazolium hexafluorophosphate and grind it in an agate mortar for 1 hour to obtain the first dispersion liquid;

[0040] (2) Dilute the first dispersion with 10 mL of N-methylpyrrolidone, transfer it to a closed glass container, and place the glass container in an ultrasonic wave with a power of 120 W for 2 hours. After cooling to room temperature, centrifuge at 12,000 rpm for 10 Minutes to collect the precipitate;

[0041] (3) Redissolve the precipitate in 50mL N-methylpyrrolidone and transfer it to an airtight glass container, place it in a constant temperature oven at 100°C for 4 hours, cool the resulting reaction solution to room temperature, and collect 90% of the upper layer with a pipette clear liquid to obtain the second dispersion liqui...

Embodiment 2

[0046] A preparation method of molybdenum disulfide quantum dots, comprising the steps of:

[0047] (1) 300 mg of molybdenum disulfide powder with a particle size of 2-4 μm is placed in an agate mortar, 1.2 g of 1-butyl-3-methylimidazolium hexafluorophosphate is added and ground for 1 hour in an agate mortar to obtain the first a dispersion;

[0048] (2) Dilute the first dispersion with 10 mL of dimethyl sulfoxide, transfer it to an airtight glass container, place the glass container in an ultrasonic wave with a power of 150 W for 1 hour, and after cooling to room temperature, centrifuge at 15,000 rpm for 5 Minutes to collect the precipitate;

[0049] (3) Redissolve the precipitate in 50 mL dimethyl sulfoxide and transfer it to a closed glass container, place it in a constant temperature oven at 95°C for 5 hours, cool the resulting reaction solution to room temperature, collect 90% of the supernatant, Obtain the second dispersion liquid;

[0050] (4) Add 45mL dimethyl sulfo...

Embodiment 3

[0054] A preparation method of molybdenum disulfide quantum dots, comprising the steps of:

[0055] (1) 200 mg of molybdenum disulfide powder with a particle size of less than 2 μm is placed in an agate mortar, 0.8 g of 1-butyl-3-methylimidazolium hexafluorophosphate is added and ground for 1 hour in an agate mortar to obtain the first Dispersions;

[0056] (2) Dilute the first dispersion with 10mL of a mixture of dimethylimidazoline and ethanol (the volume ratio of dimethylimidazoline and ethanol is 1:1), transfer it to a closed glass container, and place the glass container at a power of 100W Ultrasonic treatment for 3 hours, after cooling to room temperature, centrifuge at 10,000 rpm for 15 minutes to collect the precipitate;

[0057] (3) Re-dissolve the precipitate in 50mL of a mixture of dimethylimidazoline and ethanol (the volume ratio of dimethylimidazoline and ethanol is 1:1) and transfer it to a closed glass container, and place it in a constant temperature oven at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com