Dual-layer composite cable protection pipe and preparation method thereof

A cable protection tube, double-layer composite technology, applied in the direction of insulating cables, chemical instruments and methods, cables, etc., can solve the problems of high production cost of FRP pipes, achieve good cold and frost resistance, strong compression resistance, and reduce transportation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

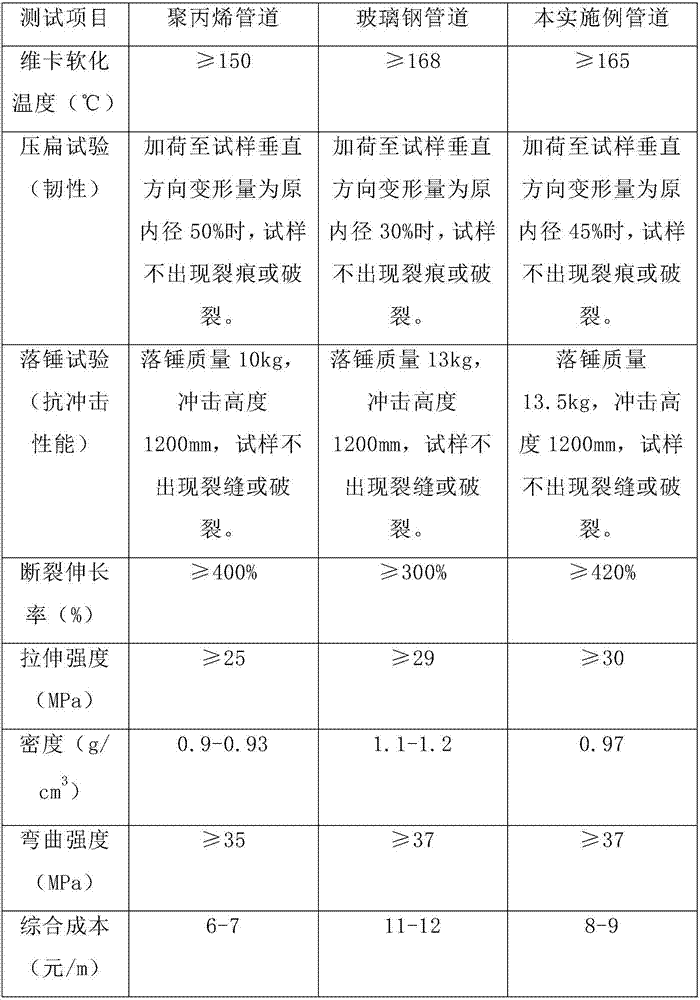

Examples

Embodiment 1

[0023] (1) Put 20 parts of epoxy resin, 15 parts of polymethyl methacrylate, 8 parts of brucite, 20 parts of nano silicon dioxide, and 8 parts of diisononyl phthalate into a high-speed mixer, heat To 240°C, stir at 700r / min for 5 minutes, mix evenly, put the mixture into the twin-screw extruder, and flow into the infiltration device after extrusion to obtain plasticized materials, 5 parts of polyacrylonitrile-based carbon fiber and 25 parts of continuous glass The fiber is pulled into the infiltration device and immersed in the plasticized material, the material is granulated, and then the granules are extruded into the composite FRP pipe through a single-screw extruder, and the composite FRP pipe is cooled to room temperature. The thickness of the composite FRP pipe wall is 5mm .

[0024] (2) 70 parts of polypropylene resin, 5 parts of low-density polyethylene resin, 1 part of dicumyl peroxide, 1 part of tetraerythritol ester, 5 parts of calcium carbonate, and 3 parts of oran...

Embodiment 2

[0027] (1) 25 parts of epoxy resin, 20 parts of polymethyl methacrylate, 10 parts of brucite, 25 parts of nano silicon dioxide, and 10 parts of diisononyl phthalate are put into a high-speed mixer, heated Stir at 750r / min for 10min to 250°C, mix evenly, put the mixture into the twin-screw extruder, and flow into the infiltration device after extrusion to obtain plasticized materials, 10 parts of polyacrylonitrile-based carbon fiber and 30 parts of continuous glass The fiber is pulled into the infiltration device and immersed in the plasticized material, the material is granulated, and then the granules are extruded into the composite FRP pipe through a single-screw extruder, and the composite FRP pipe is cooled to room temperature. The thickness of the composite FRP pipe wall is 8mm .

[0028] (2) 80 parts of polypropylene resin, 10 parts of low-density polyethylene resin, 2 parts of dicumyl peroxide, 2 parts of tetraerythritol ester, 10 parts of calcium carbonate, and 4 parts...

Embodiment 3

[0031] (1) 23 parts of epoxy resin, 18 parts of polymethyl methacrylate, 9 parts of brucite, 23 parts of nano silicon dioxide, and 9 parts of diisononyl phthalate are put into a high-speed mixer, heated Stir at 730r / min for 8 minutes to 245°C, mix evenly, put the mixture into a twin-screw extruder, and flow into the infiltration device after extrusion to obtain plasticized materials, 7 parts of polyacrylonitrile-based carbon fiber and 28 parts of continuous glass The fiber is pulled into the infiltration device and immersed in the plasticized material, the material is granulated, and then the granules are extruded into the composite FRP pipe through a single-screw extruder, and the composite FRP pipe is cooled to room temperature. The thickness of the composite FRP pipe wall is 7mm .

[0032] (2) 77 parts of polypropylene resin, 7 parts of low-density polyethylene resin, 1 part of dicumyl peroxide, 1 part of tetraerythritol ester, 8 parts of calcium carbonate, and 4 parts of o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com