Titanium dioxide added waterborne acrylic paint and preparation method thereof

A water-based acrylic and titanium dioxide technology, applied in the field of coatings, can solve the problems of destroying the continuity of the coating, the water-based acrylic paint cannot meet the demand, and the reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0053] A kind of water-based acrylic paint that is added with titanium dioxide, its specific preparation method comprises the steps:

[0054] S1, mixing the acrylic resin, dispersant, wetting agent, filler and 50wt% of water in the formulation amount, and pre-dispersing at a rotation speed of 400-600r / min to obtain a pre-dispersion system;

[0055] S2, grind the pre-dispersion system obtained in step S1, add the film-forming agent, defoamer and ethanol in the formula in order, and stir evenly; add the water of the remaining formula, and stir at the speed of 400-600r / min Evenly, that is.

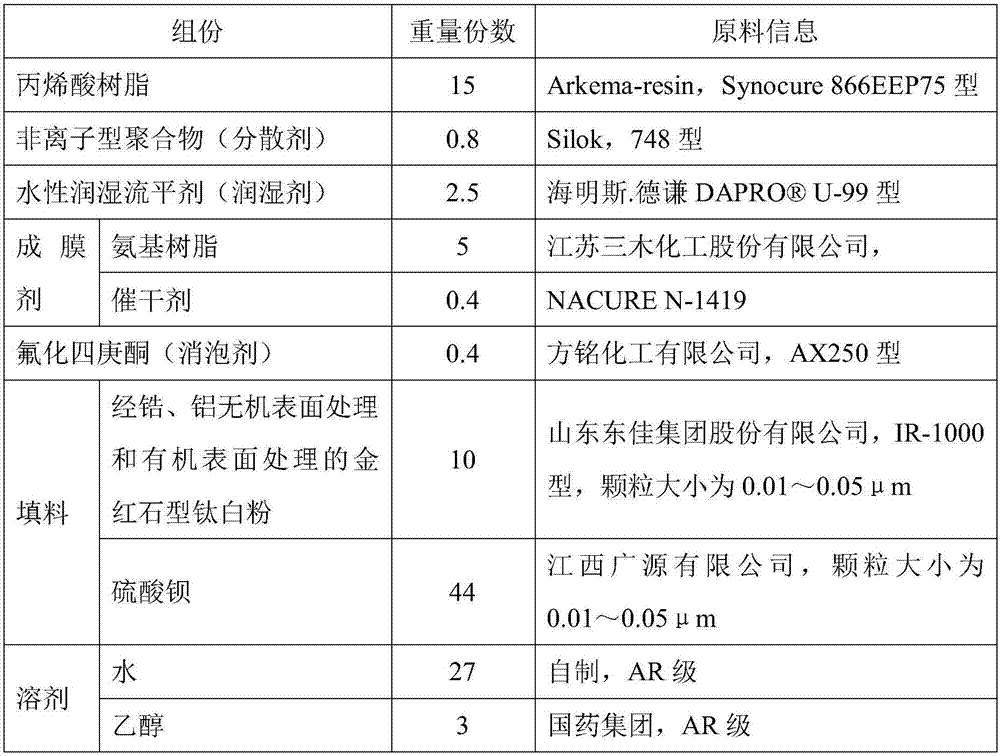

[0056] Wherein, each component and consumption amount thereof of the water-based acrylic paint added with titanium dioxide in Examples 1-5 are shown in Table 1-5.

[0057] Table 1 The formula of the waterborne acrylic paint that adds titanium dioxide in embodiment 1

[0058]

[0059] The formula of the water-based acrylic paint that adds titanium dioxide of embodiment 2 of table 2

[00...

Embodiment 6-10

[0068] A kind of water-based acrylic paint that is added with titanium dioxide, its specific preparation method comprises the steps:

[0069] S1, mixing the acrylic resin, dispersant, wetting agent, filler and 50wt% of water in the formulation amount, and pre-dispersing at a rotation speed of 400-600r / min to obtain a pre-dispersion system;

[0070] S2, grind the pre-dispersion system obtained in step S1, add the film-forming agent and defoamer in the formula in order, and add ethanol appropriately, and stir evenly; / min and stir evenly, that is to say.

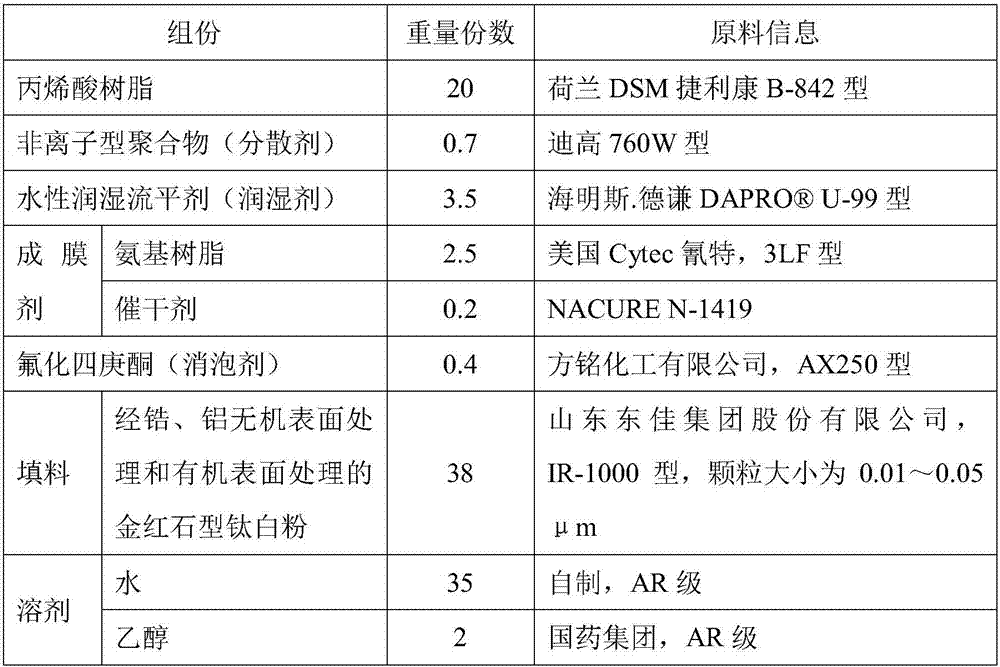

[0071] Wherein, each component and consumption amount of the water-based acrylic paint added with titanium dioxide in Example 6-8 are shown in Table 6-8.

[0072] The formula of the waterborne acrylic paint that adds titanium dioxide in embodiment 6 of table 6

[0073]

[0074] The formula of the water-based acrylic paint that adds titanium dioxide in embodiment 7 of table 7

[0075]

[0076] The formula of the water-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com