Graphene flexible composite electrode, preparation method thereof and flexible super capacitor

A technology for supercapacitors and composite electrodes, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor current collectors, etc., can solve the problems affecting the performance stability of capacitors, poor fracture resistance, etc. The effect of performance, stable performance and simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a preparation method of the graphene flexible composite electrode described in the above technical solution, comprising the following steps:

[0049] a) using a metal foam sheet as a template, using a chemical vapor deposition method to grow and deposit three-dimensional graphene on the template, and remove the metal foam sheet by chemical etching to obtain a three-dimensional graphene current collector;

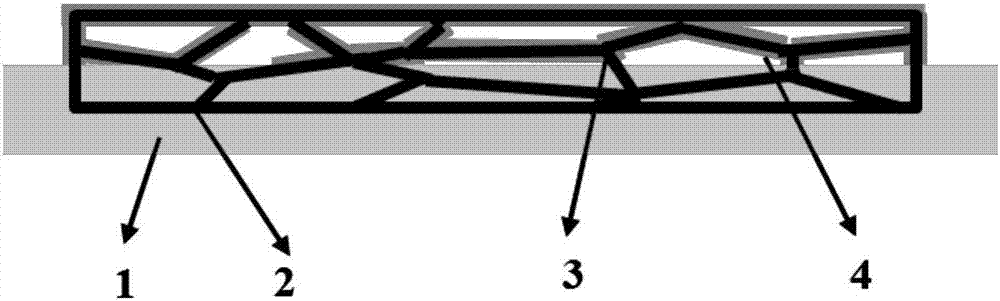

[0050] b) Coating polydimethylsiloxane colloid on the surface of the polydimethylsiloxane film, placing a part of the three-dimensional graphene current collector in the colloid, heating and curing to form an integrated substrate-collector;

[0051] c) Depositing electrode active materials on the three-dimensional graphene current collector in the integrated substrate-current collector by using an electrochemical deposition method to obtain a graphene flexible composite electrode.

[0052] According to the present invention, a metal...

Embodiment 1

[0072] 1.1 Preparation of graphene flexible composite electrode:

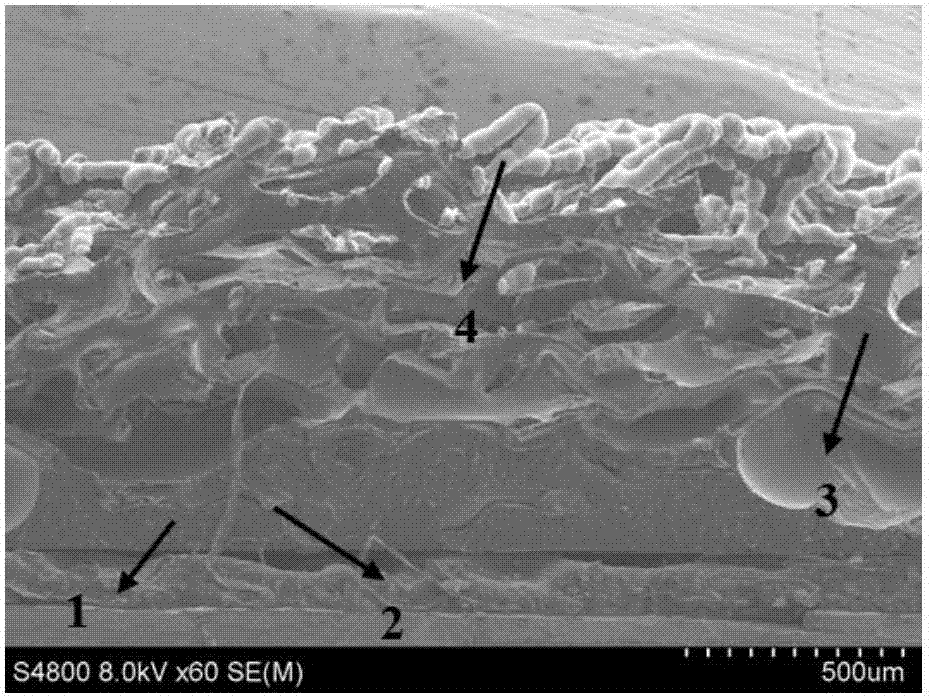

[0073] Put the foamed nickel sheet in the tube furnace, pass hydrogen gas at 180 sccm and raise the temperature to 1000°C, then pass methane at 18 sccm for 30 min; then move the furnace body through the slide rail to cool down at room temperature. The nickel foam sheet grown with three-dimensional graphene was placed in FeCl 3 In a mixed solution with HCl, the nickel foam sheet was etched and removed at 80° C., and then washed and dried with ultrapure water and ethanol in sequence to obtain a three-dimensional graphene thin film current collector.

[0074] A mixture of PDMS prepolymer and curing agent (Dow Corning SYLGARD 184 silicone rubber) with a mass ratio of 10:1 was coated on the surface of a glass plate, and heated and cured at 90°C to form a transparent PDMS film. Coating PDMS colloid (Dow Corning SYLGARD 184 silicone rubber) on the surface of the obtained PDMS film, the thickness of the colloid is low...

Embodiment 2

[0083] 1.1 Preparation of graphene flexible composite electrode:

[0084] Put the foamed nickel sheet in the tube furnace, pass hydrogen gas at 180 sccm and raise the temperature to 1000°C, then pass methane at 18 sccm for 30 min; then move the furnace body through the slide rail to cool down at room temperature. The nickel foam sheet grown with three-dimensional graphene was placed in FeCl 3 In a mixed solution with HCl, the nickel foam sheet was etched and removed at 80° C., and then washed and dried with ultrapure water and ethanol in sequence to obtain a three-dimensional graphene thin film current collector.

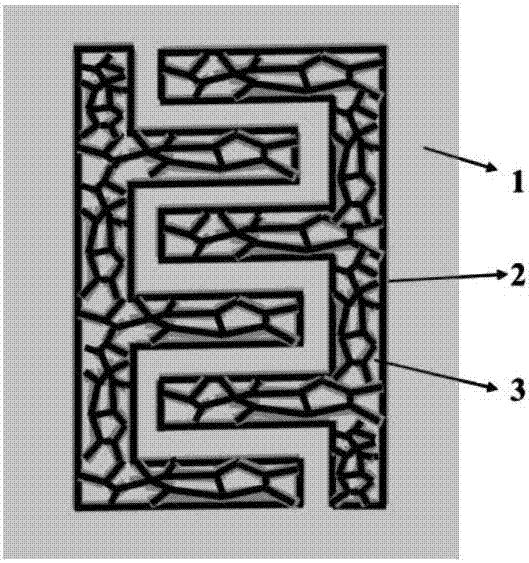

[0085] The obtained three-dimensional graphene thin film current collector was photolithographyed with a laser beam of 532nm, the spot size was 10 μm, and the photolithography power of the laser beam was 0.5W, to obtain an interdigitated current collector.

[0086] A mixture of PDMS prepolymer and curing agent (Dow Corning SYLGARD 184 silicone rubber) with a mass r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com