Non-heat insulation type composite fireproof glass and manufacturing method thereof

A technology for fireproof glass and glass layer, applied in chemical instruments and methods, glass/slag layered products, non-polymer adhesive additives, etc., can solve the problems of easy self-explosion, low sampling yield and high production cost, Achieve the effect of maintaining fire-resistant integrity, protecting life and property, and preventing conduction and radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

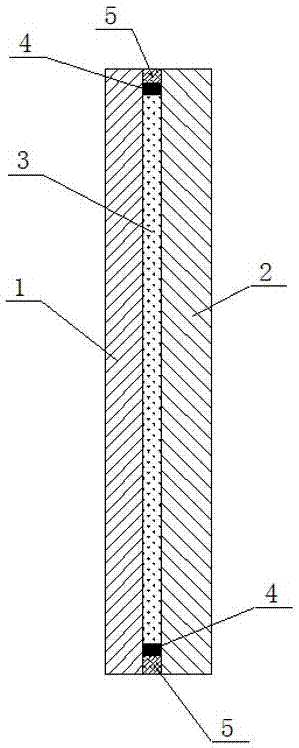

Embodiment 1

[0047] The structure of the non-heat-insulating composite fireproof glass in this embodiment: the fire-proof glass layer adopts 3mm float glass, the back-fire glass layer adopts 5mm toughened glass, and the thickness of the inorganic transparent fireproof adhesive layer is 1mm. The composite fire-resistant glass described in this example is suitable for fire-proof windows for building exterior windows, performance indicators: visible light transmittance 85%; fire-resistant integrity ≥ 60min; cold-resistant performance: no change in appearance at a constant temperature of -20°C for 6 hours; heat-resistant performance : There is no change in appearance at 50°C for 6 hours; after 100 hours of ultraviolet radiation resistance test, the visible light transmittance does not change more than 10%.

[0048] The preparation method of non-heat-insulating composite fireproof glass described in this embodiment:

[0049] 1. First, cut, edge and chamfer the fire-facing glass layer (3mm float...

Embodiment 2

[0054] The structure of the non-heat-insulating composite fireproof glass in this embodiment: the fireproof glass layer adopts 5mm tempered glass, the fireproof glass layer adopts 5mm tempered glass, and the thickness of the inorganic transparent fireproof adhesive layer is 2mm. The composite fire-resistant glass described in this example is suitable for fire-proof windows for building exterior windows, performance indicators: visible light transmittance 84%; fire-resistant integrity ≥ 60min; cold-resistant performance: no change in appearance at a constant temperature of -20°C for 6 hours; heat-resistant performance : There is no change in appearance at 50°C for 6 hours; after 100 hours of ultraviolet radiation resistance test, the visible light transmittance does not change more than 10%.

[0055] The preparation method of non-heat-insulating composite fireproof glass described in this embodiment:

[0056] 1. Cut, grind, chamfer, and physically toughen the fire-oriented glas...

Embodiment 3

[0061] The structure of the non-heat-insulating composite fireproof glass in this embodiment: 6mm float glass is used for the fire-facing glass layer, 6mm float glass is used for the back-fire glass layer, and the thickness of the inorganic transparent fireproof adhesive layer is 5mm. The composite fire-resistant glass described in this example is suitable for fire-proof windows for building exterior windows, performance indicators: visible light transmittance 80%; fire-resistant integrity ≥ 60min; heat insulation 30min; cold resistance: no change in appearance at a constant temperature of -20°C for 6h ; Heat resistance: No change in appearance at a constant temperature of 50°C for 6 hours; after 100 hours of ultraviolet radiation resistance test, the visible light transmittance does not change more than 10%.

[0062] The preparation method of non-heat-insulating composite fireproof glass described in this embodiment:

[0063]1. First, cut, grind, chamfer and physically toughe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com