Cuprous oxide nanometer pn homojunction material of core-shell structure and preparation method thereof

A core-shell structure, homojunction technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problem of unreported homojunction arrays, and achieve excellent photoelectrochemical performance, tight coating, and crystal lattice. Small mismatch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

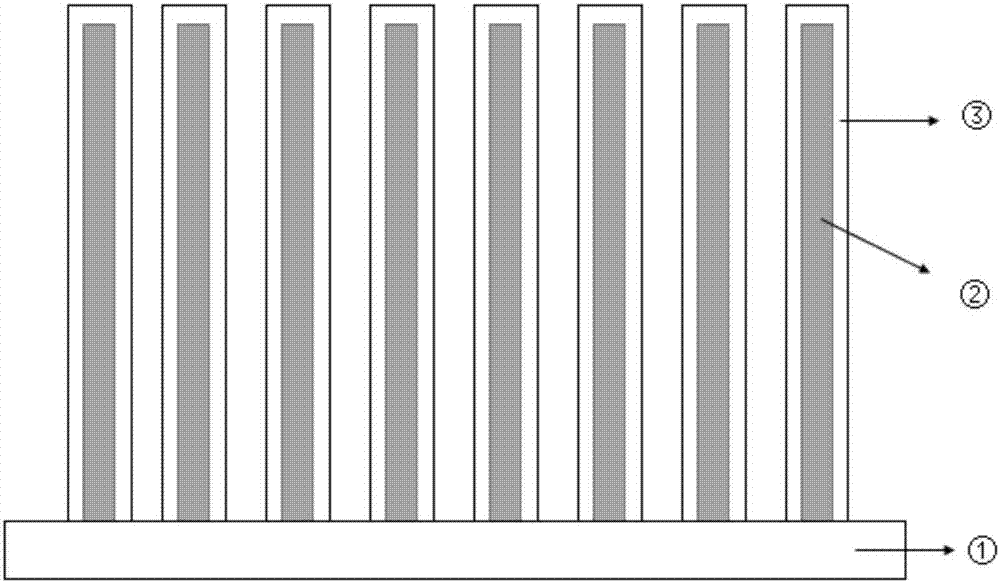

[0020] 1) Substrate pretreatment: Cut the copper sheet into 1cm×2cm size, strip the surface, place it in an ultrasonic cleaning machine with deionized water and ethanol for 10 minutes, and then dry it with nitrogen;

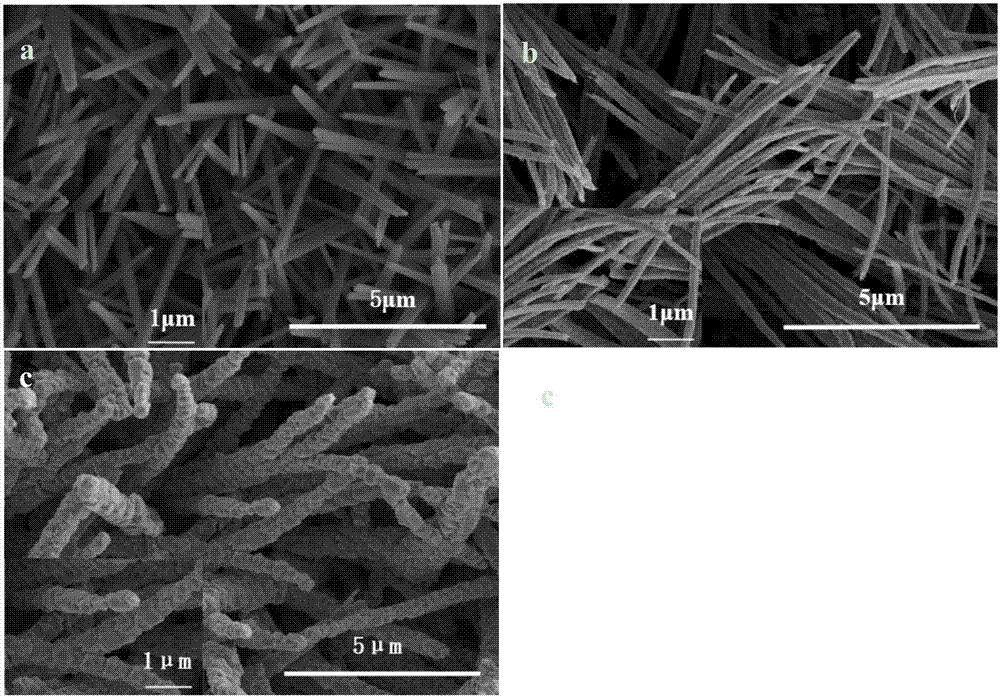

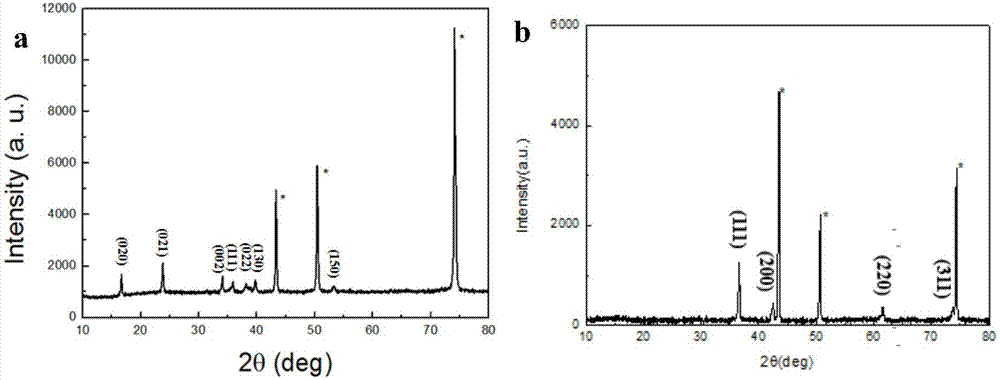

[0021] 2)p-Cu 2 O nanorod array preparation: configure 5M NaOH solution, pour the NaOH solution into the electrolytic cell, use the copper sheet substrate as the working electrode, Ag / AgCl as the reference electrode, and platinum wire as the counter electrode to form a standard three-electrode system ; At room temperature, a 30mA constant current is applied to the working electrode to obtain Cu(OH) 2 Nanorod array precursor; the Cu(OH) 2 The nanorod array precursor is placed in an inert protective gas, and the temperature is slowly raised to 500°C at 3°C / min for annealing treatment to obtain p-Cu 2 O nanorod arrays.

[0022] 3) n-Cu 2 Preparation of O coating layer: prepare 0.02M Cu(CH 3 COO) 2 solution, 0.08M CH 3 COOH solution and 5mM KCl solution were m...

Embodiment 2

[0024] 1) Substrate pretreatment: Cut the copper sheet into 1cm×2cm size, strip the surface, place it in an ultrasonic cleaning machine with deionized water and ethanol for 10 minutes, and then dry it with nitrogen;

[0025] 2)p-Cu 2 Fabrication of O nanorod arrays: Preparation of Cu(OH) by wet chemistry 2 Precursor, prepare 4ml of 8M NaOH solution and 2ml of 1M (NH 4 )S 2 o 8 solution, after stirring and mixing evenly, place the above-mentioned copper sheet at the bottom of the beaker, and react at room temperature; react for 4 minutes, immediately take out the copper sheet and rinse it repeatedly with deionized water, and air-dry it at room temperature to obtain Cu(OH) 2 Precursor; the Cu(OH) 2 The precursor is placed in a vacuum tube furnace for annealing, and argon is introduced, and the temperature is raised to 500°C at a rate of 5°C / min, and then cooled with the furnace to obtain p-type Cu 2 O nanorods.

[0026] 3) n-Cu 2 Preparation of O coating layer: prepare 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com