Method for coloring magnesium material micro-arc oxidation coating through weak acid dye

A weak acid dye, micro-arc oxidation technology, applied in anodizing and other directions, can solve problems such as complex operation, corrosion, environmental pollution, etc., achieve high binding force and wear resistance, simple production process, and improve corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

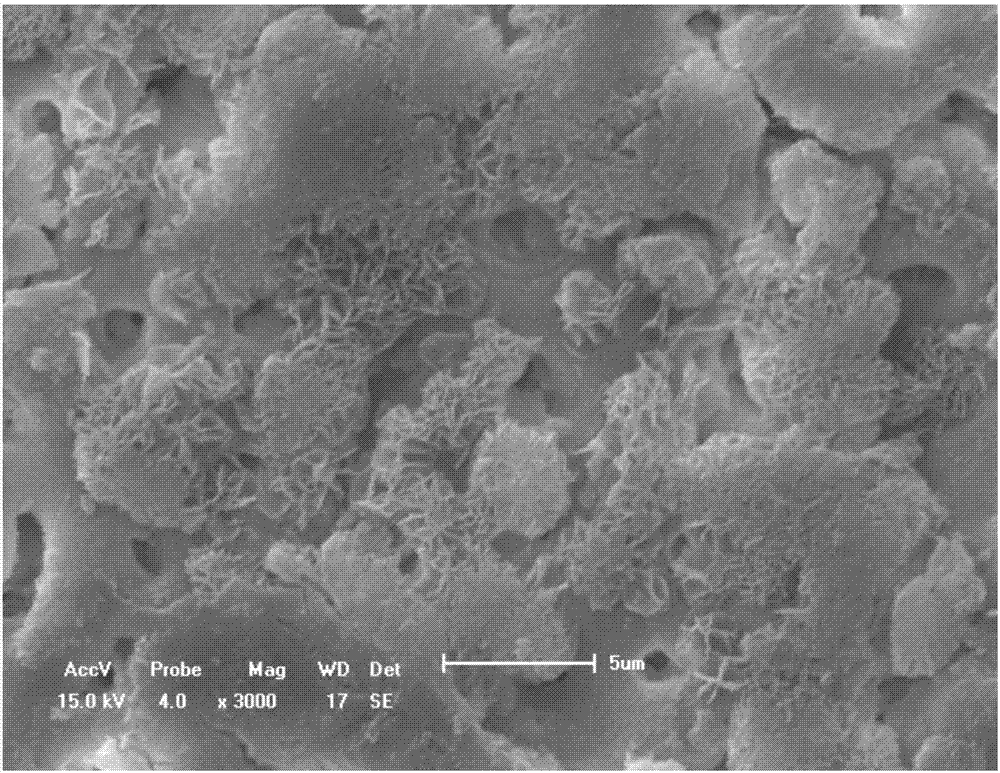

[0023] (1) Use dyeing solution to soak and color the in-situ grown micro-arc oxidation film layer on the surface of the magnesium material. The soaking time for soaking and coloring is 1 to 12 hours, and the soaking time can be freely adjusted according to the depth of the required staining. The longer the dyeing, the deeper the dyeing, so that the magnesium micro-arc oxidation film layer can present various bright and bright colors.

[0024] (2) adopt dyeing solution to carry out immersion coloring to the in-situ growth micro-arc oxidation film layer on the surface of the magnesium material, it is best to carry out on the coloring equipment; Coloring equipment, and in the soaking and coloring process, the stirring speed of the stirring device of the coloring equipment is 500-1000r / min, the temperature of the constant temperature device of the coloring equipment is 20-40°C, and the ultrasonic generation of the coloring equipment The power of the device can be adjusted from 100...

Embodiment 1

[0033]A kind of method that utilizes weak acid dyestuff to be the method for the magnesium material micro-arc oxidation coating coloring, adopts the AZ31 magnesium alloy disk that radius is 15mm, thickness is 3mm as the magnesium material substrate to be treated, and its concrete procedure comprises:

[0034] (1) Pretreatment process: use 400#, 600#, 800#, 1000#, 1200#, 1500# sandpaper to grind the surface of the AZ31 magnesium alloy disc from coarse to fine, and then polish it in turn , ultrasonic cleaning (absolute ethanol or acetone can be used for ultrasonic cleaning), and drying, so as to obtain the pretreated AZ31 magnesium alloy disc.

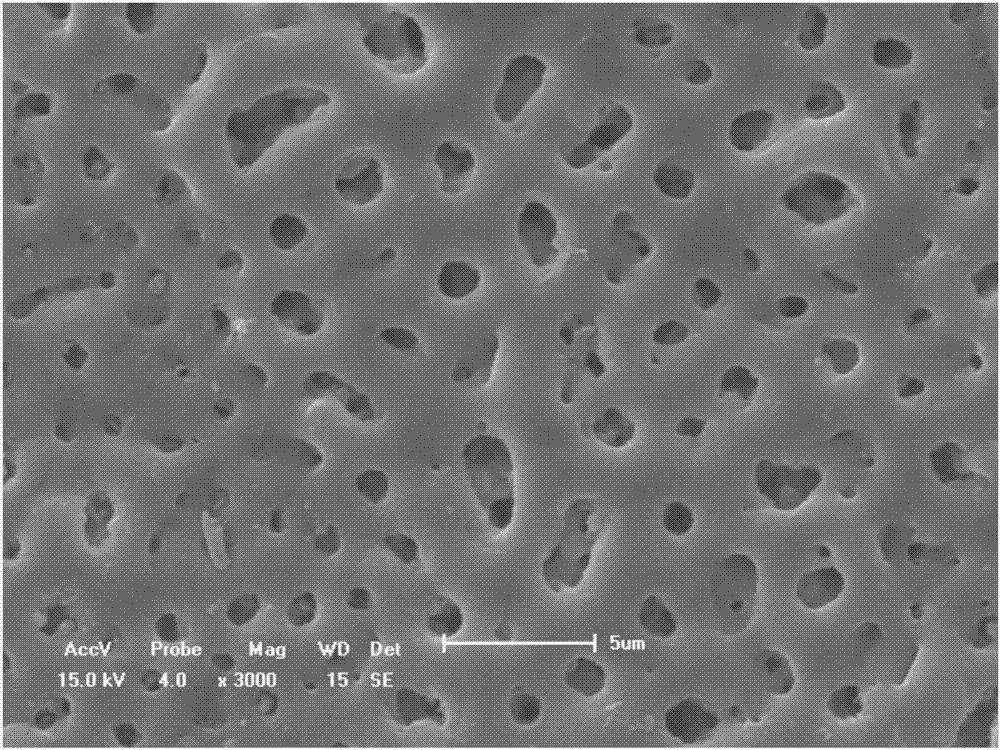

[0035] (2) Micro-arc oxidation process: use micro-arc oxidation technology to carry out surface treatment on the pretreated AZ31 magnesium alloy disc to grow a white micro-arc oxidation film on the surface of the AZ31 magnesium alloy disc in situ.

[0036] Specifically, the micro-arc oxidation electrolyte is poured into the reaction tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com