Modified ethylene propylene terpolymer and preparation method

A modification technology of EPDM rubber, which is applied in the field of rubber, can solve the problems of poor dispersion of modified EPDM rubber, and achieve the effects of enhanced flame resistance, high reactivity, and improved polymer strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

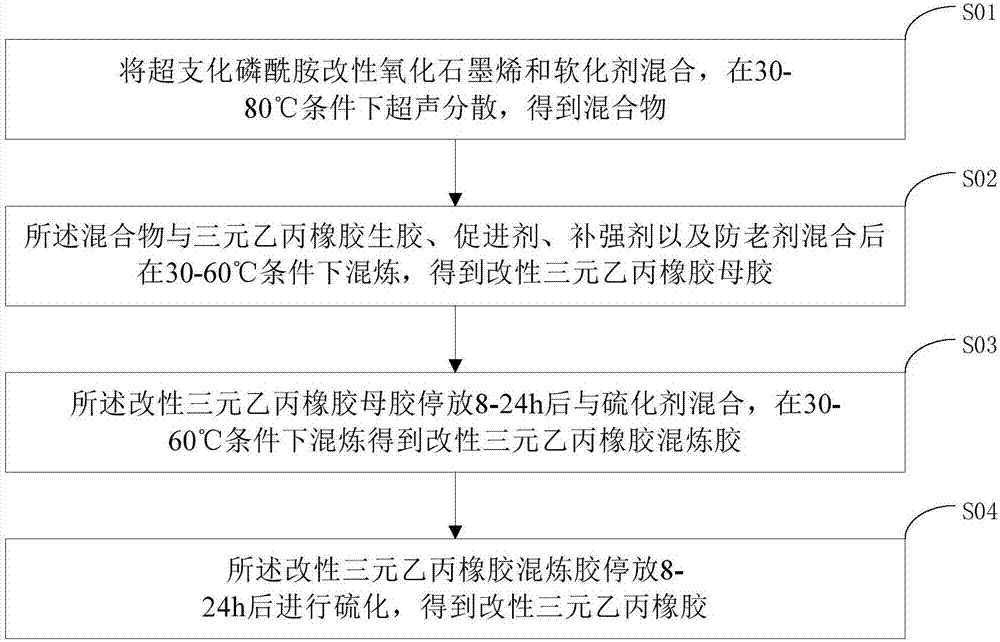

Method used

Image

Examples

Embodiment 1

[0041] The embodiment of the present invention provides a modified EPDM rubber, the modified EPDM rubber includes:

[0042] 100 parts of raw EPDM rubber, 6 parts of accelerator, 40 parts of reinforcing agent, 1.5 parts of antiaging agent, 15 parts of softener, 5 parts of hyperbranched phosphoramide modified graphene oxide, and 1 part of vulcanizing agent.

[0043] The embodiment of the present invention also provides a preparation method of the modified EPDM rubber. In the specific description of the method, the usage content of each raw material is as shown above. The method provided by the embodiment of the present invention specifically includes:

[0044] S101: Weigh graphene oxide, and dissolve graphene oxide in chloroform. The mixture of graphene oxide and chloroform was ultrasonically exfoliated for 2 hours at a temperature of 30° C. and an ultrasonic power of 400 W to obtain a graphene oxide suspension. Phosphorus oxychloride, ethylenediamine and anhydrous ferric chl...

Embodiment 2

[0051] The embodiment of the present invention provides a modified EPDM rubber, the modified EPDM rubber includes:

[0052] 100 parts of raw EPDM rubber, 6 parts of accelerator, 40 parts of reinforcing agent, 1.5 parts of antiaging agent, 15 parts of softener, 8 parts of hyperbranched phosphoramide modified graphene oxide, and 1 part of vulcanizing agent.

[0053] The embodiment of the present invention also provides a preparation method of the modified EPDM rubber. In the specific description of the method, the usage content of each raw material is as shown above. The specific steps of the method provided in the embodiment of the present invention are the same as in embodiment 1, except that the mass fraction of the hyperbranched phosphoramide-modified graphene oxide is 8 parts.

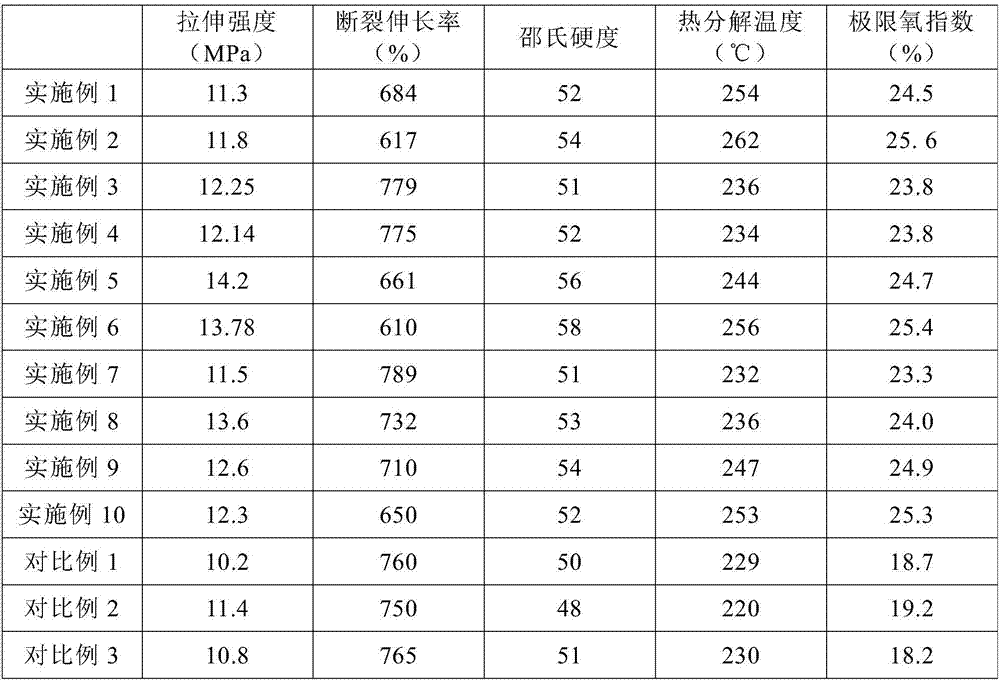

[0054] After testing, the modified EPDM rubber prepared in the embodiment of the present invention has a tensile strength of 11.8 MPa, an elongation at break of 617%, a Shore hardness of 54, a maxi...

Embodiment 3

[0056] The embodiment of the present invention provides a modified EPDM rubber, the modified EPDM rubber includes:

[0057] 100 parts of raw EPDM rubber, 6 parts of accelerator, 40 parts of reinforcing agent, 1.5 parts of antiaging agent, 15 parts of softener, 3 parts of hyperbranched phosphoramide modified graphene oxide, and 1 part of vulcanizing agent.

[0058] The embodiment of the present invention also provides a preparation method of the modified EPDM rubber. In the specific description of the method, the usage content of each raw material is as shown above. The specific steps of the method provided in the embodiment of the present invention are the same as in embodiment 1, except that the mass fraction of the hyperbranched phosphoramide-modified graphene oxide is 3 parts, and the vulcanizing agent is benzoyl peroxide.

[0059] After testing, the modified EPDM rubber prepared in the embodiment of the present invention has a tensile strength of 12.25MPa, an elongation a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Maximum thermal decomposition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com