ZnFe2O4/C composite nanometer fiber super capacitor electrode material and preparation method thereof

A technology of composite nanofibers and supercapacitors, which is applied in the fields of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nanotechnology, etc., can solve the problems of poor rate performance and cycle stability, and easy falling off of electrode materials, and achieves a simple preparation method easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

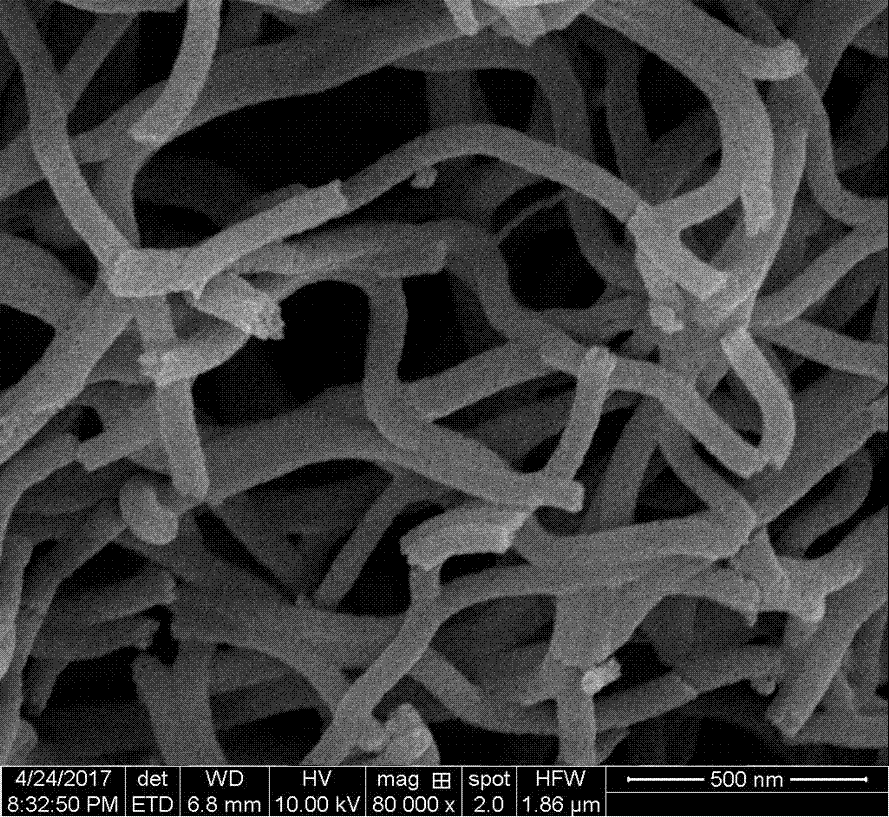

[0029] 0.4 mmol ferric chloride hexahydrate, 0.2 mmol anhydrous zinc chloride, 0.5 g PAN and 10 mL DMF were mixed and stirred evenly to fully dissolve the solid matter to obtain the precursor sol. The above precursor sol was placed in a syringe connected to a high-voltage DC power supply. The diameter of the pinhole nozzle was 0.5 nm, the applied voltage was set to 15 kV, and the injection speed was set to 0.04 mm / min. Electrospinning was started to prepare PAN / ZnCl 2 / FeCl 3Precursor composite nanofiber mat, drying. The dried samples were placed in a tube furnace to undergo three steps of pre-oxidation treatment, calcination in a low-temperature air atmosphere, and calcination in a high-temperature Ar atmosphere: the first step was pre-oxidation heat treatment, and the temperature was kept at 250 °C for 4 h in an air atmosphere. 5 ℃ / min; the second step is calcination in low-temperature air atmosphere, 400 ℃ for 4 h, and the heating rate is 5 ℃ / min; the third step is calci...

Embodiment 2

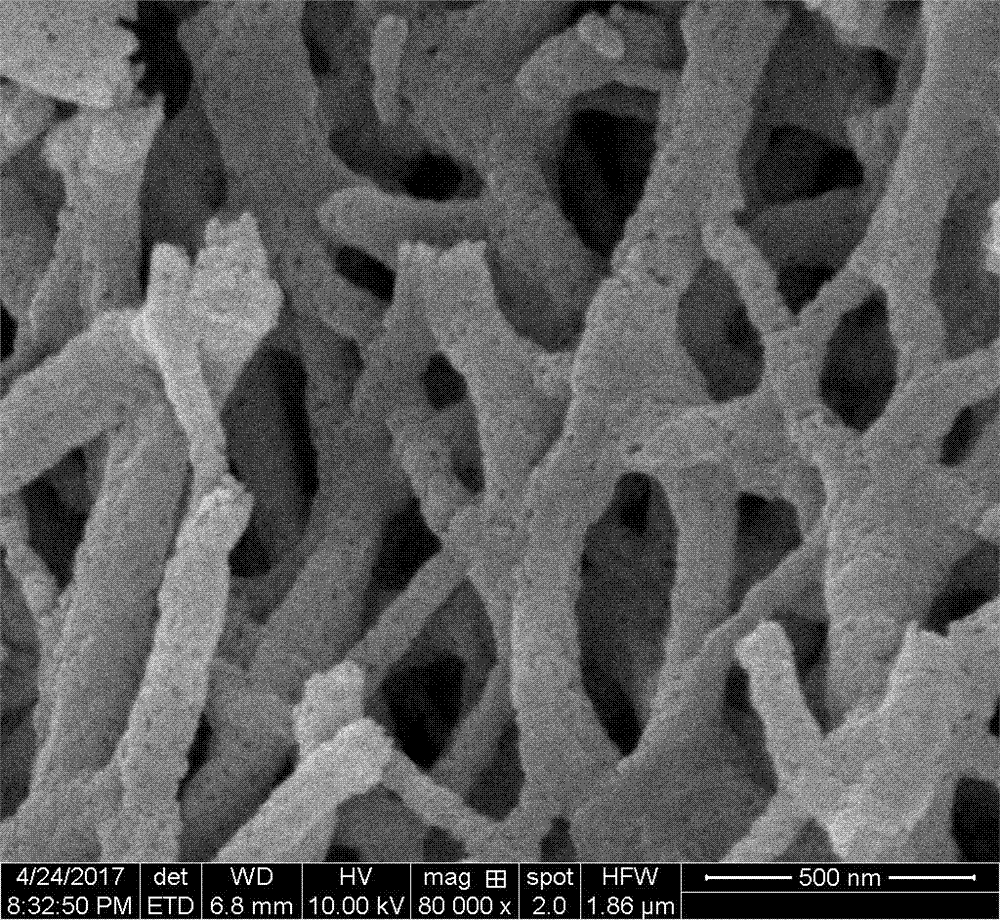

[0031] 0.4 mmol ferric chloride hexahydrate, 0.2 mmol anhydrous zinc chloride, 1 g PAN and 10 mL DMF were mixed and stirred evenly to fully dissolve the solid matter to obtain the precursor sol. The above precursor sol was placed in a syringe connected to a high-voltage DC power supply. The diameter of the pinhole nozzle was 0.6 nm, the applied voltage was set to 16 kV, and the injection speed was set to 0.07 mm / min. Electrospinning was started to prepare PAN / ZnCl 2 / FeCl 3 Precursor composite nanofiber mat, drying. The dried samples were placed in a tube furnace and gradually underwent three-step heat treatment: pre-oxidation treatment, calcination in a low-temperature air atmosphere, and calcination in a high-temperature Ar atmosphere: the first step was pre-oxidation heat treatment, and the temperature was kept at 270 °C for 3 h in an air atmosphere. 5 ℃ / min; the second step is calcination in low-temperature air atmosphere, 450 ℃ for 3 h, and the heating rate is 5 ℃ / min;...

Embodiment 3

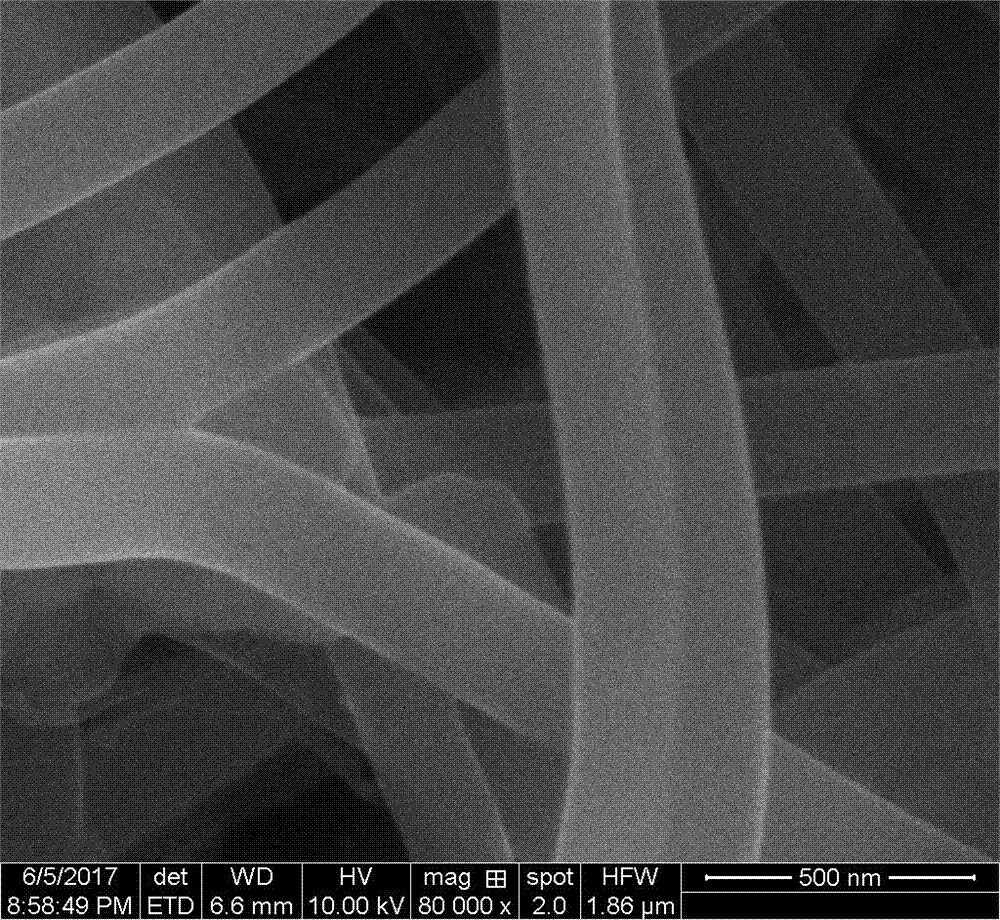

[0033] 0.4 mmol ferric chloride hexahydrate, 0.2 mmol anhydrous zinc chloride, 1.5 g PAN and 10 mL DMF were mixed and stirred evenly to fully dissolve the solid matter to obtain the precursor sol. The above precursor sol was placed in a syringe connected to a high-voltage DC power supply. The diameter of the pinhole nozzle was 0.7 nm, the applied voltage was set to 17 kV, and the injection speed was set to 0.1 mm / min. Electrospinning was started to prepare PAN / ZnCl 2 / FeCl 3 Precursor composite nanofiber mat, drying. The dried samples were placed in a tube furnace and gradually underwent three-step heat treatment: pre-oxidation treatment, calcination in a low-temperature air atmosphere, and calcination in a high-temperature Ar atmosphere: the first step was pre-oxidation heat treatment, and the temperature was kept at 300 °C for 2 h in an air atmosphere. 5 ℃ / min; the second step is calcination in low-temperature air atmosphere, holding at 500 ℃ for 2 h, and the heating rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com