A method for growing large-domain graphene using hexagonal boron nitride as point seeds

A technology of hexagonal boron nitride and graphene, which is applied in the field of graphene preparation to achieve the effect of improving growth quality, ensuring nucleation density and uniform layer number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

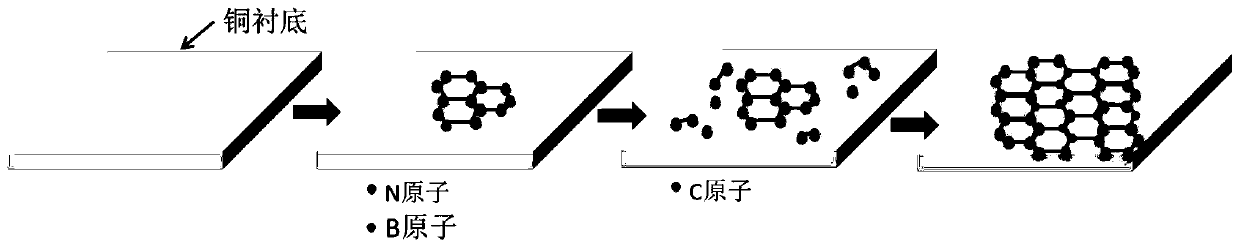

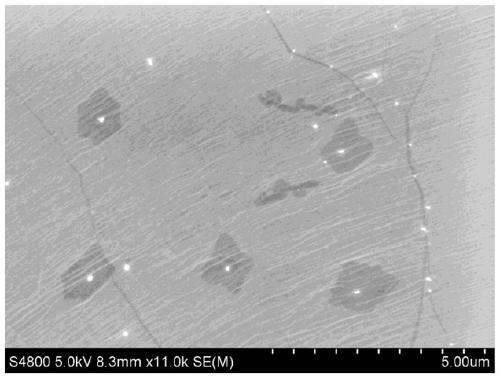

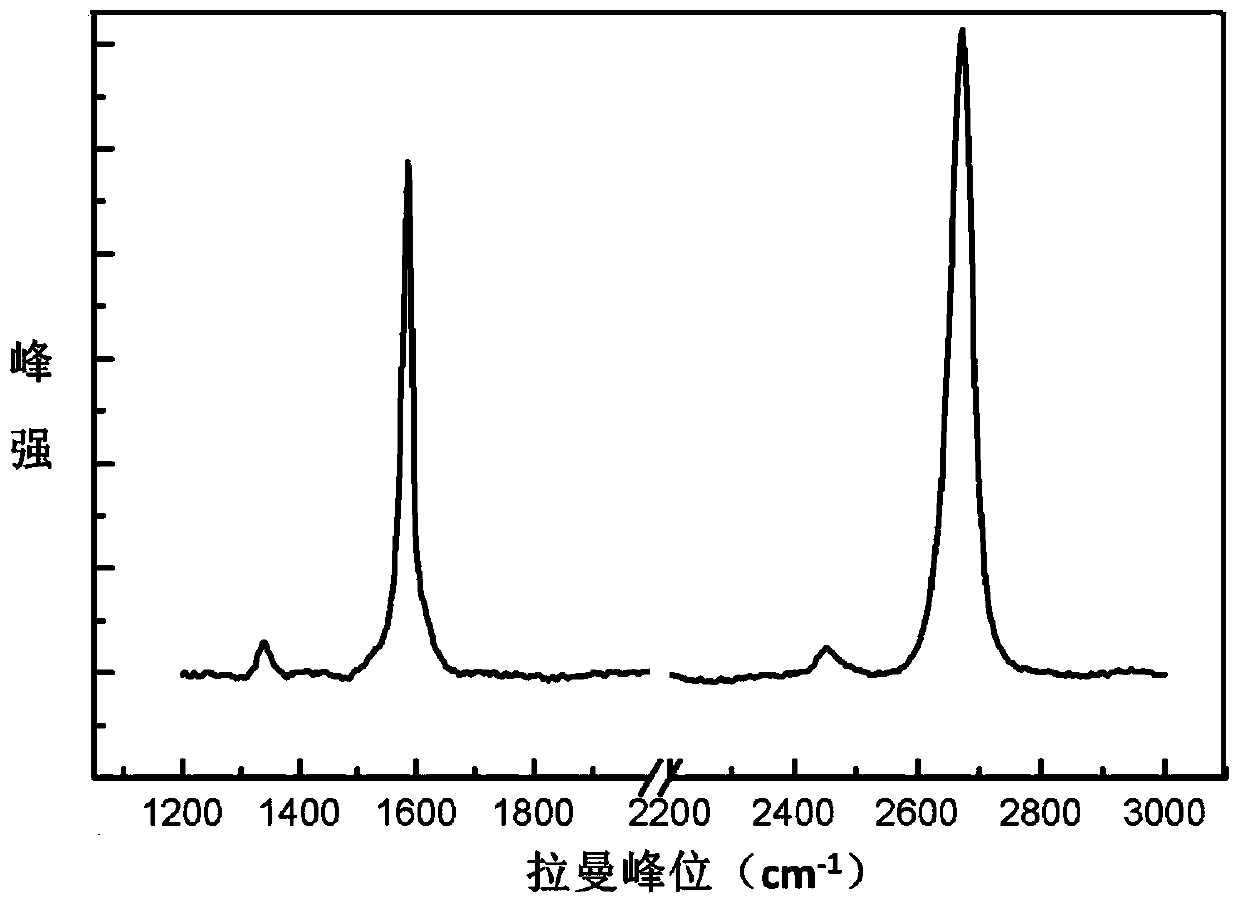

[0039] A method for positioning and growing large-domain graphene by using hexagonal boron nitride as a point seed crystal, taking a copper substrate as an example, comprising the following steps:

[0040] (1) The copper foil with a thickness of 25 μm is polished and cleaned; the hexagonal boron nitride powder is dissolved in 60ml of ethanol solution, and then stirred and ultrasonically treated. The stirring and ultrasonic time are 10min and 20min, so that the boron nitride particles are evenly dispersed , and then let it stand for 3 hours, and then use Scotch tape to peel and transfer the boron nitride to the surface of the copper foil.

[0041] (2) Place the processed copper foil in (1) flat in the quartz boat of the CVD tube furnace, and the vacuum degree of the high-temperature CVD graphene growth furnace chamber is 10 -3 Pa, the temperature is raised to 300°C, and the heating rate is 10°C / min; high-purity argon and hydrogen are introduced, the flow rates of argon and hydr...

Embodiment 2

[0045] A method for positioning and growing large-domain graphene by using hexagonal boron nitride as a point seed crystal, taking a copper substrate as an example, comprising the following steps:

[0046] (1) The copper foil with a thickness of 25 μm is polished and cleaned; the hexagonal boron nitride powder is dissolved in 40ml of ethanol solution, and then stirred and ultrasonically treated. The stirring and ultrasonic time are 10min and 20min, so that the boron nitride particles are evenly dispersed , and then let it stand for 3 hours, and then use Scotch tape to peel and transfer the boron nitride to the surface of the copper foil.

[0047] (2) Place the processed copper foil in (1) flat in the quartz boat of the CVD tube furnace, and the vacuum degree of the high-temperature CVD graphene growth furnace chamber is 10 -3 Pa, the temperature is raised to 300°C, and the heating rate is 10°C / min; high-purity argon and hydrogen are introduced, the flow rates of argon and hydr...

Embodiment 3

[0050] A method for positioning and growing large-domain graphene by using hexagonal boron nitride as a point seed crystal, taking a copper substrate as an example, comprising the following steps:

[0051] (1) The copper foil with a thickness of 25 μm is polished and cleaned; the hexagonal boron nitride powder is dissolved in 40ml of acetone solution, and then stirred and ultrasonically treated. The stirring and ultrasonic time are 10min and 20min, so that the boron nitride particles are evenly dispersed , and then let it stand for 3 hours, and then use Scotch tape to peel and transfer the boron nitride to the surface of the copper foil.

[0052] (2) Place the processed copper foil in (1) flat in the quartz boat of the CVD tube furnace, and the vacuum degree of the high-temperature CVD graphene growth furnace chamber is 10 -3 Pa, the temperature is raised to 300°C, and the heating rate is 10°C / min; high-purity argon and hydrogen are introduced, the flow rates of argon and hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com