Nano-copper array cathode for reductive degradation of organic pollutants as well as preparation and application thereof

A technology of organic pollutants and nano-copper, applied in water pollutants, water/sewage treatment, water/sludge/sewage treatment, etc. Problems such as being too scattered, achieving the effect of being suitable for large-scale production, compact arrangement, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Take 6×2.5cm 2 Copper foam, ultrasonically soaked with acetone for 15 minutes, cleaned with ultrapure water, then ultrasonically soaked with 1% sulfuric acid for 15 minutes, cleaned with ultrapure water, and dried;

[0039] (2) Get 250mL electrolyte in 260mL electrolytic cell, take step (1) copper foam as working electrode, mixed oxide (MMO) electrode as counter electrode, Ag / AgCl saturated KCl as reference electrode, form three-electrode system; The electrolyte composition is: 0.03mol / L copper sulfate (CuSO 4 ·5H 2O), 0.0025mol / L nickel sulfate (NiSO 4 ·6H 2 O), 0.24mol / L sodium dihydrogen phosphate (NaH 2 PO 4 ·H 2 O), 0.05mol / L sodium citrate (Na 3 C 6 h 5 o 7 2H 2 O), 0.50mol / L boric acid (H 3 BO 3 );

[0040] (3) Set the cathode potential to -0.92V, carry out constant potential deposition at room temperature, the deposition time is 10 minutes, wash with ultrapure water and dry for later use.

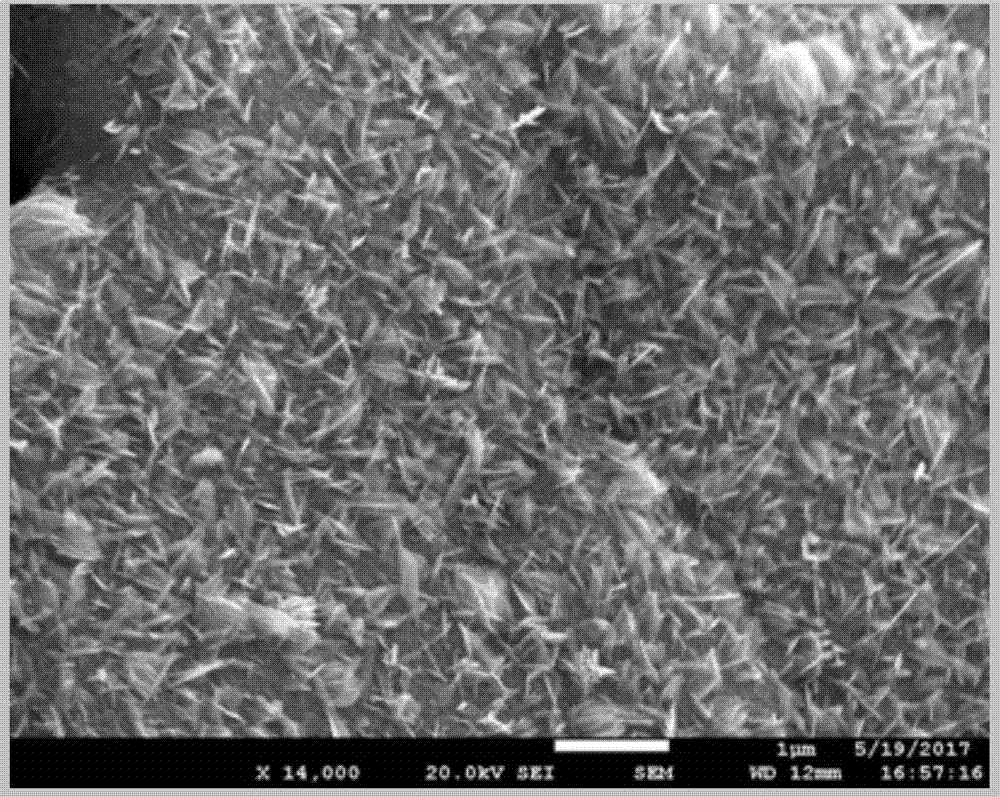

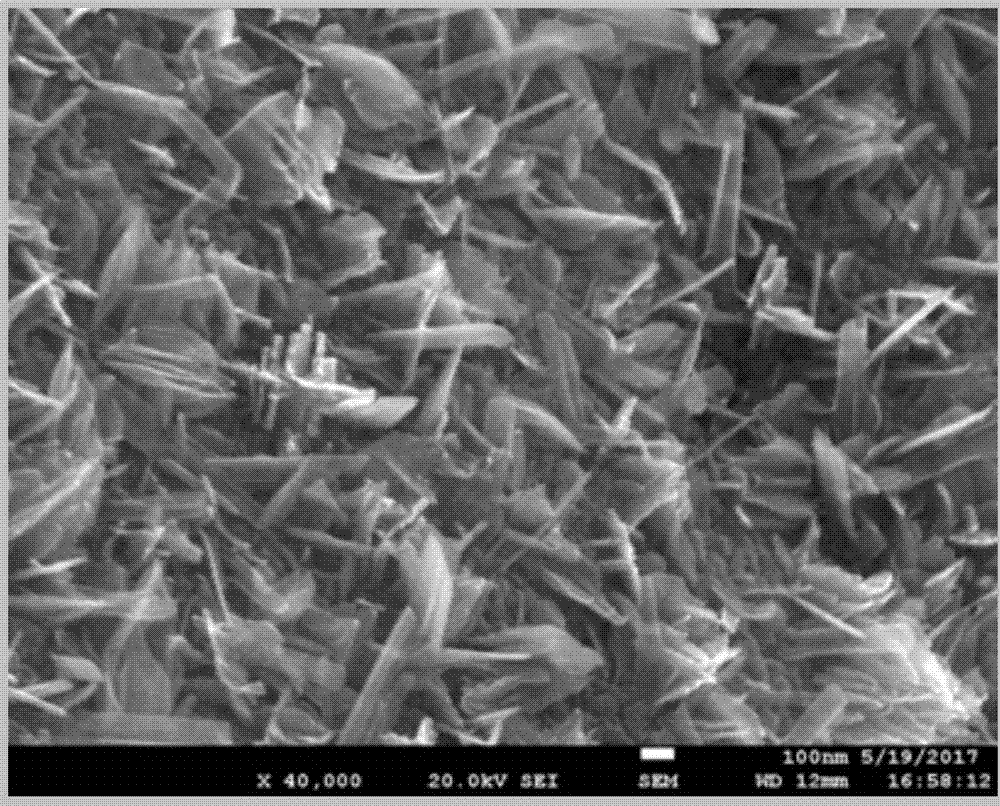

[0041] Figure 1 ~ Figure 2 Shown is the topography ...

Embodiment 2

[0045] (1) Take 6×2.5cm 2 Copper foam, ultrasonically soaked with acetone for 15 minutes, cleaned with ultrapure water, then ultrasonically soaked with 1% sulfuric acid for 15 minutes, cleaned with ultrapure water, and dried;

[0046] (2) Get 250mL electrolyte in 260mL electrolytic cell, take step (1) copper foam as working electrode, mixed oxide (MMO) electrode as counter electrode, Ag / AgCl saturated KCl as reference electrode, form three-electrode system; The electrolyte composition is: 0.03mol / L copper sulfate (CuSO 4 ·5H 2 O), 0.0025mol / L nickel sulfate (NiSO 4 ·6H 2 O), 0.24mol / L sodium dihydrogen phosphate (NaH 2 PO 4 ·H 2 O), 0.05mol / L sodium citrate (Na 3 C 6 h 5 o 7 2H 2 O), 0.50mol / L boric acid (H 3 BO 3 );

[0047] (3) Set the cathode potential to -0.92V, carry out constant potential deposition at room temperature, the deposition time is 15 minutes, wash with ultrapure water and dry for later use.

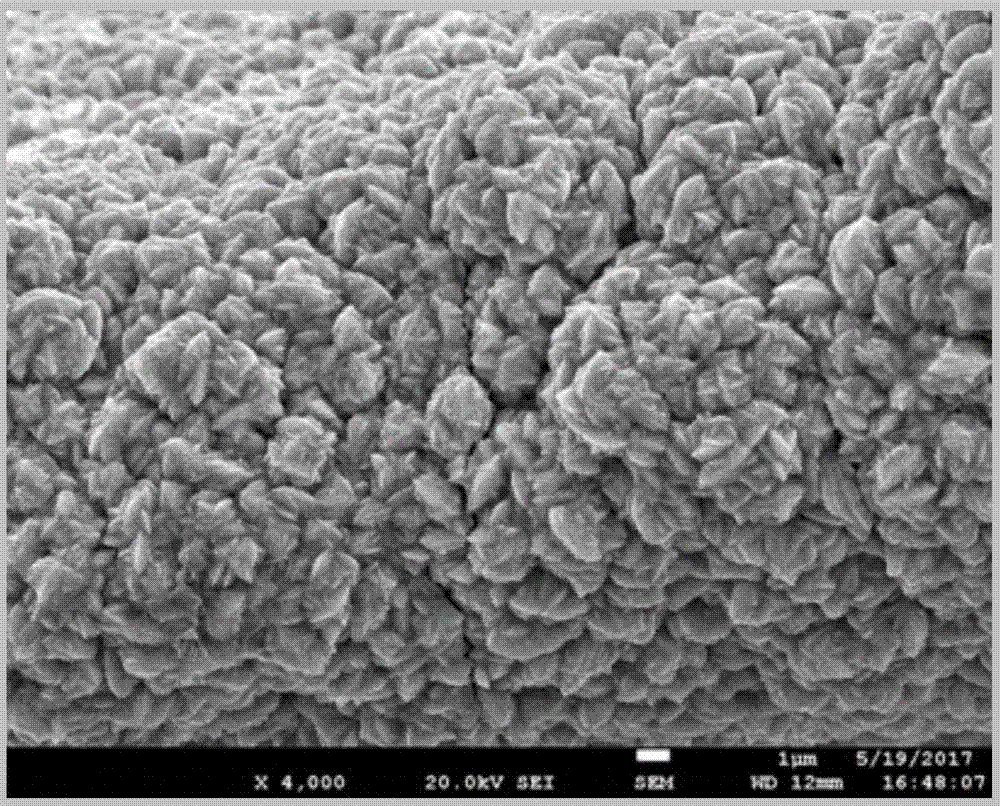

[0048] The morphology of the nano-copper array catho...

Embodiment 3

[0052] (1) Take 6×2.5cm 2 Copper foam, ultrasonically soaked with acetone for 15 minutes, cleaned with ultrapure water, then ultrasonically soaked with 1% sulfuric acid for 15 minutes, cleaned with ultrapure water, and dried;

[0053] (2) Get 250mL electrolyte in 260mL electrolytic cell, take step (1) copper foam as working electrode, mixed oxide (MMO) electrode as counter electrode, Ag / AgCl saturated KCl as reference electrode, form three-electrode system; The electrolyte composition is: 0.03mol / L copper sulfate (CuSO 4 ·5H 2 O), 0.0025mol / L nickel sulfate (NiSO 4 ·6H 2 O), 0.24mol / L sodium dihydrogen phosphate (NaH 2 PO 4 ·H 2 O), 0.05mol / L sodium citrate (Na 3 C 6 h 5 o 7 2H 2 O), 0.50mol / L boric acid (H 3 BO 3 );

[0054] (3) Set the cathode potential to -0.92V, carry out constant potential deposition at room temperature, the deposition time is 5 minutes, wash with ultrapure water and dry for later use.

[0055] The nano-copper array cathode prepared in Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com