Universal environment-friendly building glue and preparation method thereof

A construction glue, general-purpose technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of bonding strength not as good as 801 glue, easy to fluff and roll, high manufacturing cost, and achieve environmentally friendly curing time , The effect of high raw material utilization and low equipment demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

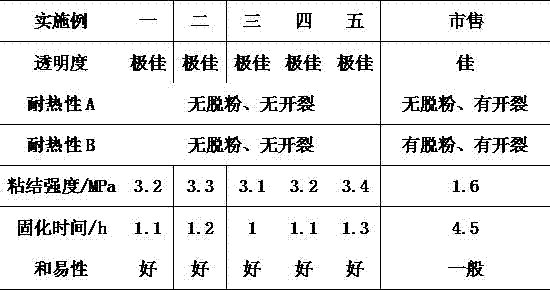

Examples

Embodiment 1

[0021] A kind of universal environment-friendly construction glue proposed by the present invention comprises the following raw materials in parts by weight: 60 parts of epoxy resin, 30 parts of acrylic resin, 10 parts of aluminum hydroxide gel, 12 parts of xanthan gum, 16 parts of glycerin, polyethylene glycol 6 parts of diol 300, 4 parts of sodium dodecylbenzenesulfonate, 12 parts of sodium carboxymethyl cellulose, 4 parts of dibenzylidene sorbitol, 1 part of antioxidant, 2 parts of water retaining agent, 4 parts of stabilizer, the composition 4 parts of nuclear agent, 4 parts of antifungal agent, 50 parts of ethanol, 20 parts of water.

[0022] Its preparation method comprises the following steps:

[0023] S1: Put the corresponding weight parts of epoxy resin and acrylic resin in a pulverizer to pulverize into particles with a particle size of 100 mesh or more, and then put the pulverized particles in a melting machine for 20 minutes at 80°C to obtain a resin solution;

[...

Embodiment 2

[0027] A kind of universal environment-friendly building glue proposed by the present invention comprises the following raw materials in parts by weight: 45 parts of epoxy resin, 50 parts of acrylic resin, 10 parts of aluminum hydroxide gel, 10 parts of xanthan gum, 12 parts of glycerin, polyethylene glycol 8 parts of diol 600, 5 parts of sodium dodecylbenzenesulfonate, 10 parts of sodium carboxymethyl cellulose, 3 parts of dibenzylidene sorbitol, 0.8 parts of antioxidant, 3 parts of water-retaining agent, 6 parts of stabilizer. 4 parts of nuclear agent, 4 parts of antifungal agent, 42 parts of ethanol, 25 parts of water.

[0028] Its preparation method comprises the following steps:

[0029] S1: Put the corresponding weight parts of epoxy resin and acrylic resin in a pulverizer to pulverize into particles with a particle size of 100 mesh or more, and then put the pulverized particles in a melting machine for 15 minutes at 70°C to obtain a resin solution;

[0030] S2: Put the...

Embodiment 3

[0033] A kind of universal environment-friendly building glue proposed by the present invention comprises the following raw materials in parts by weight: 40 parts of epoxy resin, 30 parts of acrylic resin, 14 parts of aluminum hydroxide gel, 5 parts of xanthan gum, 14 parts of glycerin, polyethylene 10 parts of diol 1000, 3 parts of sodium dodecylbenzene sulfonate, 10 parts of sodium carboxymethyl cellulose, 4 parts of dibenzylidene sorbitol, 0.5 parts of antioxidant, 4 parts of water retaining agent, 2 parts of stabilizer. 4 parts of nuclear agent, 2 parts of antifungal agent, 32 parts of ethanol, 28 parts of water.

[0034] Its preparation method comprises the following steps:

[0035] S1: Put the corresponding weight parts of epoxy resin and acrylic resin in a pulverizer to pulverize into particles with a particle size of 100 mesh or more, and then put the pulverized particles in a melting machine at 80°C for 10 minutes to obtain a resin solution;

[0036] S2: Put the corr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com