Preparation process and application of beta-carotene nano-emulsion

A technology of carotene and preparation process, which is applied in the direction of application, skin care preparations, medical preparations of non-active ingredients, etc., which can solve the problems of poor product stability, poor stability requirements, safety risks, etc., and achieve the goal of overcoming poor stability , Improve production efficiency, no safety risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

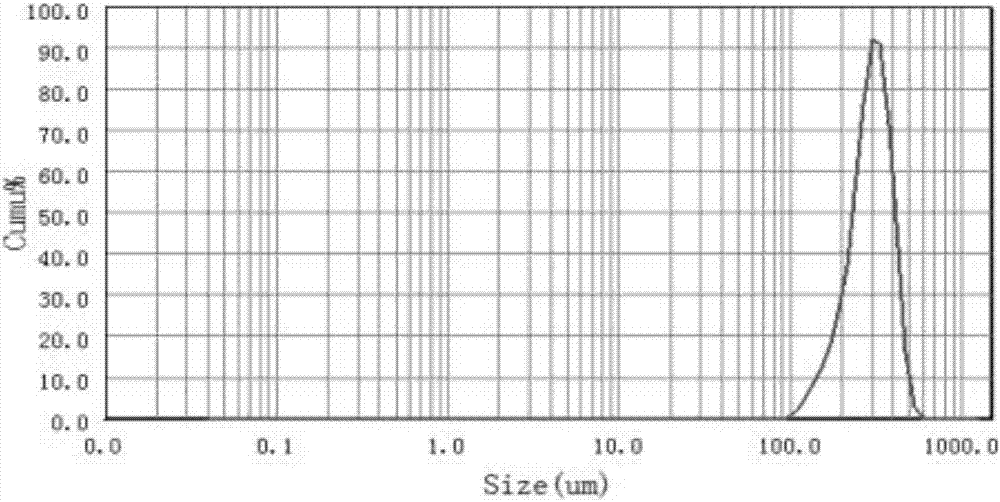

[0030] Embodiment 1: Traditional technology produces β-carotene emulsion

[0031] 1. Stir 10 kg of β-carotene (96% content), 75 kg of soybean oil, 75 kg of medium-chain triglycerides and 0.5 kg of vitamin E to form an oil phase, and heat to 130-140°C to dissolve it Obtain oil phase material, stand-by;

[0032] 2. Add 50 kg of soybean lecithin, 0.5 kg of sodium sulfite, and 80 kg of glycerin into 600L of water, heat up to 70°C under normal pressure to fully dissolve, and set aside;

[0033] 3. Add the oil phase to the water phase, then shear and emulsify for 20 minutes, and homogenize at 50Mpa-70Mpa for 3 times to make the final emulsion.

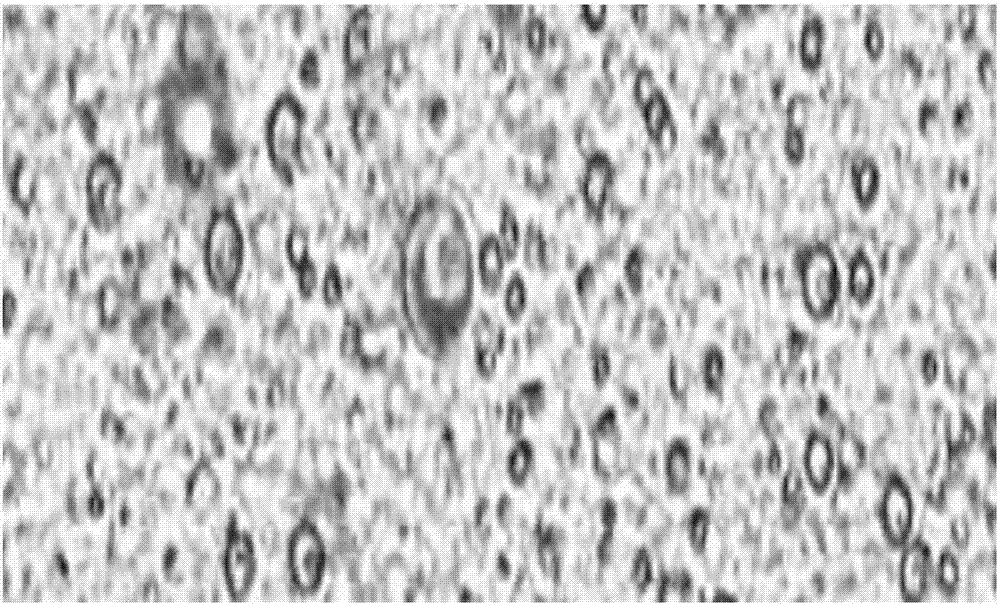

Embodiment 2

[0034] Embodiment 2: the preparation method of a kind of β-carotene nanoemulsion of the present invention

[0035] (1) 140 kilograms of glycerin, 15 kilograms of modified soybean lecithin, 14.5 kilograms of polyglycerol fatty acid esters, and 70 kilograms of high HLB auxiliary emulsifiers are added to 1000 kilograms of water, and the temperature is raised to 70 ° C under normal pressure to fully dissolve and stand-by;

[0036] (2) take by weighing 10 kilograms of β-carotene (content is 96%), 8 kilograms of sucrose fatty acid lipids, 10 kilograms of caprylic acid glycerides, 20 kilograms of Span 60, 0.4 kilograms of oil phase antioxidant vitamin E dissolved in 151.6 Kg of sunflower oil, stir quickly to dissolve it when heated to 130-140°C, stir evenly to obtain oil phase material, set aside;

[0037] (3) Discharge the dissolved water phase material and oil phase material at the same time, respectively control the flow rate of the water phase and the oil phase, according to the ...

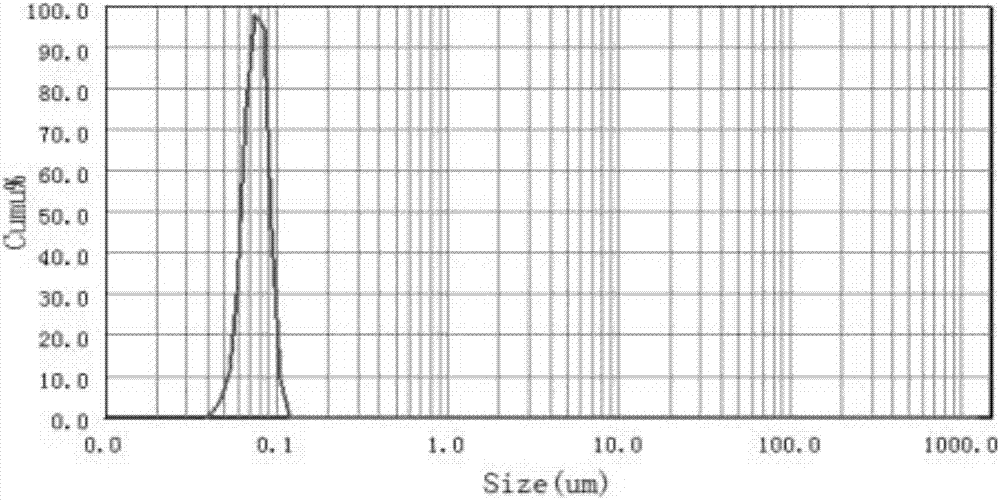

Embodiment 3

[0038]Embodiment 3: the preparation method of a kind of β-carotene nanoemulsion of the present invention

[0039] (1) 180 kilograms of glycerin, 45 kilograms of modified soybean lecithin, 15 kilograms of polyglycerol fatty acid esters, and 75 kilograms of high HLB auxiliary emulsifiers are added to 1000 kilograms of water, and the temperature is raised to 70 ° C under normal pressure to fully dissolve, and it is ready to use;

[0040] (2) take by weighing 35 kilograms of β-carotene (content is 96%), 18 kilograms of sucrose fatty acid lipids, 28 kilograms of caprylic acid glycerides, 52 kilograms of Span 60 and 0.8 kilograms of oil phase antioxidant vitamin E dissolved in 166 Kg of olive oil, stir quickly to dissolve when heated to 130-140°C, stir evenly to obtain oil phase material, set aside;

[0041] (3) Discharge the dissolved water phase material and oil phase material at the same time, respectively control the flow of the water phase and the oil phase, according to the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com