Rubber composition for tire tread and preparation method of rubber composition

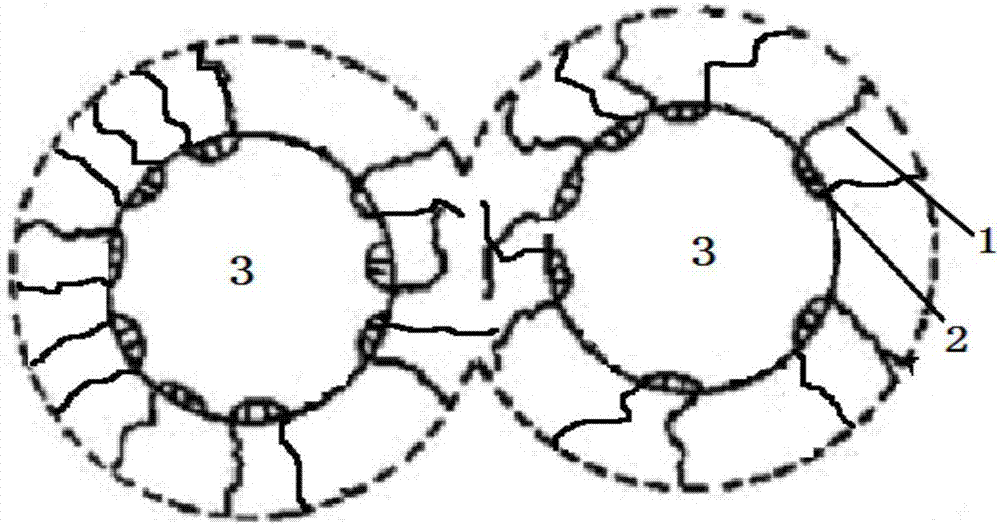

A technology of rubber composition and tire tread, which is applied to special tires, tire parts, vehicle parts, etc., and can solve problems such as uneven dispersion, poor bonding between nano-silica and rubber matrix, and easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

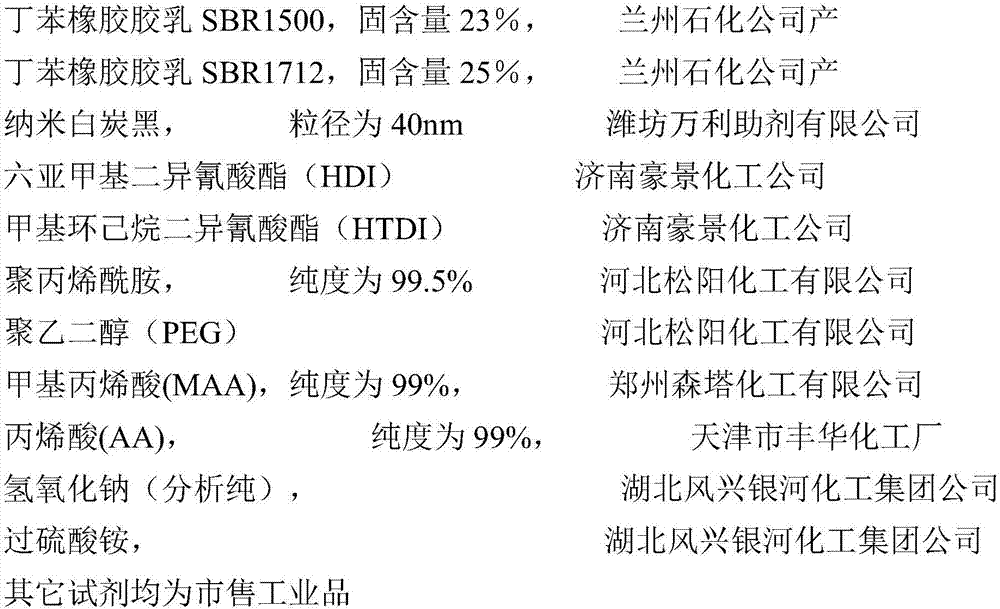

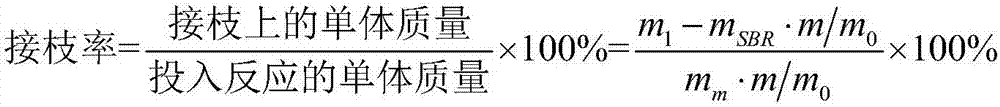

[0035] (1) Preparation of grafted styrene-butadiene latex: according to the mass parts of styrene-butadiene latex SBR1500, first add 120 parts of deionized water in the polymerization kettle, then add 100 parts of styrene-butadiene latex SBR1500, 2.0 parts of dodecylbenzene Sodium sulfonate, 0.3 parts of dodecyl mercaptan, after replacing with nitrogen, then add 5.5 parts of MAA, stir and heat, add 0.2 parts of ammonium persulfate when the temperature of the polymerization kettle reaches 35 °C, react for 3.5 hours, add 0.2 parts of diethylhydroxylamine to prepare grafted styrene-butadiene latex (SBR-g-MAA). Sampling analysis: the measured grafting rate of SBR-g-MAA was 2.1%.

[0036] (2) Preparation of modified nano-silica: according to the mass parts of nano-silica, 100 parts of nano-silica and 220 parts of deionized water were added to the polymerization kettle and stirred and mixed for 15 minutes; Methyl diisocyanate (HDI), 1.2 parts of sodium hydroxide, stir and heat up t...

Embodiment 2

[0039] (1) Preparation of grafted styrene-butadiene latex: with embodiment 1.

[0040] (2) Preparation of modified nano white carbon black: with embodiment 1.

[0041] (3) Preparation of the styrene-butadiene rubber composition for tire tread: according to the mass parts of styrene-butadiene latex SBR1500 (dry matrix), get 100 parts of styrene-butadiene latex SBR1500 and 2.0 parts of SBR-g-MAA (grafting rate 2.1%), 3.0 parts of sodium dodecylbenzenesulfonate, and 230 parts of deionized water were added to the coagulation kettle and stirred and mixed for 15 minutes, then 30 parts of modified nano-silica were added, and the pH value of the system was adjusted with sodium bicarbonate 8.5, when the temperature is raised to 60°C, stir and mix for 40 minutes, then add 3.5 parts of hydrochloric acid for coagulation, and finally wash, dehydrate, dry, and briquette to obtain a styrene-butadiene rubber composition for tire treads. Sampling analysis: standard samples were made by vulcan...

Embodiment 3

[0043] (1) Preparation of grafted styrene-butadiene latex: according to the mass parts of styrene-butadiene latex SBR1500, first add 150 parts of deionized water in the polymerization kettle, then add 100 parts of styrene-butadiene latex SBR1500, 5.0 parts of dodecylbenzene Sodium sulfonate, 0.5 parts of dodecyl mercaptan, after replacing with nitrogen, then add 7 parts of MAA, stir and heat, add 0.3 parts of ammonium persulfate when the temperature of the polymerization kettle reaches 35 °C, react for 3.5 hours, add 0.4 parts of diethylhydroxylamine to prepare grafted styrene-butadiene latex (SBR-g-MAA). Sampling analysis: the measured grafting rate of SBR-g-MAA was 2.9%.

[0044] (2) Preparation of modified nano-silica: according to the mass parts of nano-silica, 100 parts of nano-silica and 300 parts of deionized water were added to the polymerization kettle and stirred for 20 minutes; Methyl diisocyanate (HDI), 1.4 parts of sodium hydroxide, stir and heat up to 50°C, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com