One-component low-viscosity dealcoholized silicone potting adhesive and preparation method thereof

A low-viscosity technology of silicone potting glue, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of application limitations, short storage period of glue, metal copper polycarbonate plastic corrosion, etc. , to achieve good economic and social benefits, good adhesion of potting adhesive, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

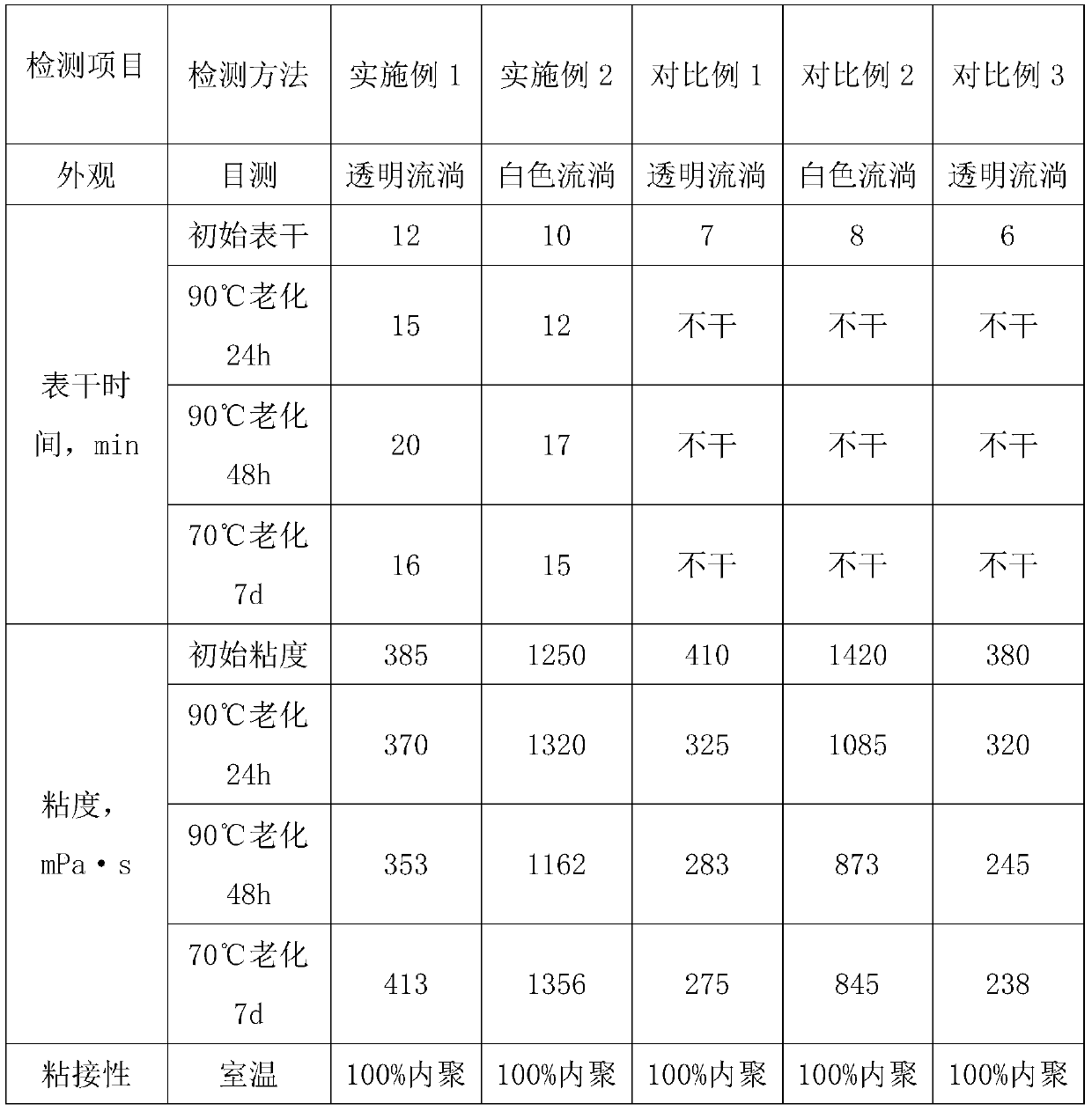

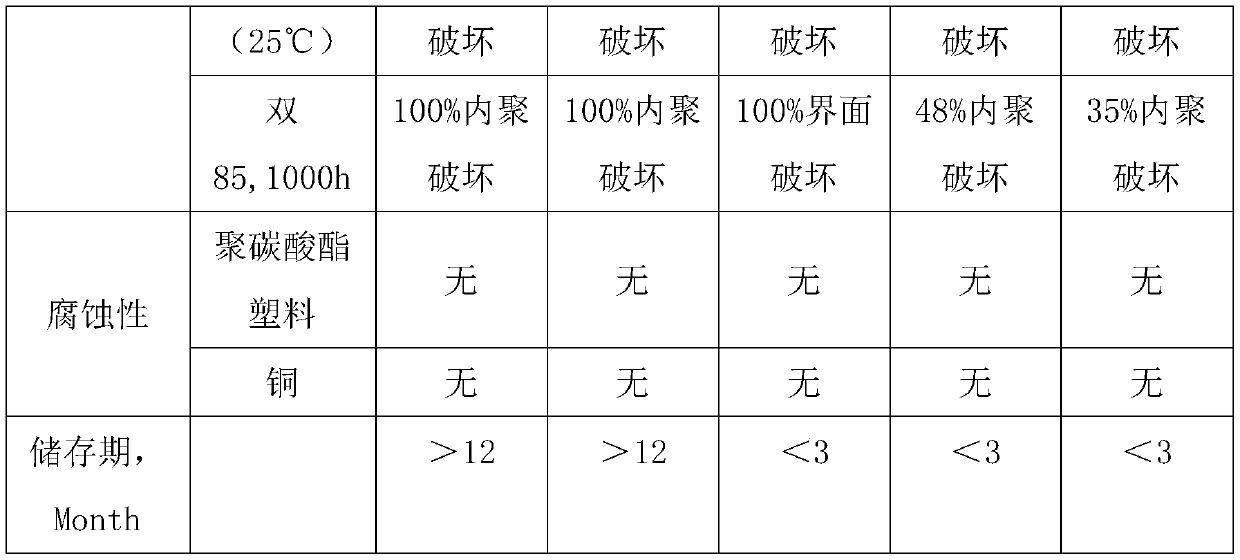

Examples

Embodiment 1

[0030] (1) Put 100 parts of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 400mPa·s and 2 parts of tetramethoxysilane into a stirring tank, stir evenly under vacuum, and then add 0.003 parts Sodium hydroxide, stirred in vacuum for 40 minutes, then added 0.008 parts of acetic acid, and continued to stir in vacuum for 60 minutes to obtain alkoxy-terminated polydimethylsiloxane.

[0031] (2) the chelated tin catalyst is the reflux of dibutyltin dilaurate and ethyl acetoacetate, and the preparation process is: in the reactor, add dibutyltin dilaurate and ethyl acetoacetate in a weight ratio of 1:1, Reflux at 60°C for 60 minutes. After cooling, the chelated tin catalyst is obtained.

[0032] (3) Add 100 parts of alkoxy-terminated polydimethylsiloxane, 4 parts of dimethyl silicone oil, and 5 parts of methyltrimethoxysilane into the stirred tank, stir in vacuum for 30 minutes, and then add 1 part in turn N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane, 0.5 part of γ-glycidyl...

Embodiment 2

[0035] (1) Put 100 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 1000mPa·s and 2.5 parts of vinyltrimethoxysilane into a stirring tank, stir evenly under vacuum, and then add 0.004 part of potassium hydroxide, stirred in vacuum for 40 minutes, then added 0.01 part of phosphoric acid, and continued to stir in vacuum for 60 minutes to obtain alkoxy-terminated polydimethylsiloxane.

[0036] (2) The chelated tin catalyst is the reflux of dibutyltin dilaurate and ethyl acetoacetate, and the preparation process is: in the reactor, add dibutyltin dilaurate and ethyl acetoacetate in a mass ratio of 1:2, Reflux at 80°C for 60 minutes. After cooling, the chelated tin catalyst is obtained.

[0037] (3) Add 100 parts of alkoxy-terminated polydimethylsiloxane and 6 parts of silicon micropowder into the kneader, heat up to 120°C under vacuum conditions, dehydrate for 3 hours, and cool to room temperature to obtain Binder.

[0038] (4) Add 106 parts of base material, 5 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com