Automobile air-conditioning compressor lubricating oil

A technology for automotive air conditioners and lubricating oils, applied in lubricating compositions, the petroleum industry, etc., can solve problems such as compressor wear and tear, compressor abnormal noise, etc., and achieve the effects of reducing friction, reducing abnormal noise, and prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

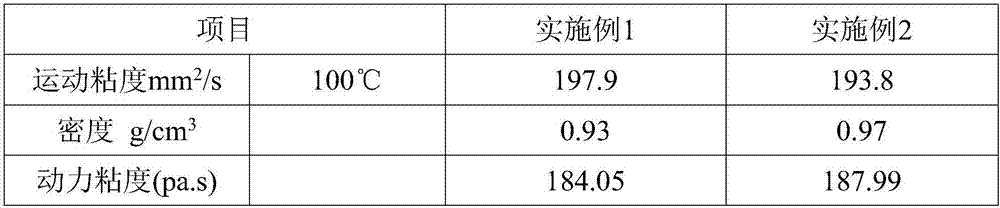

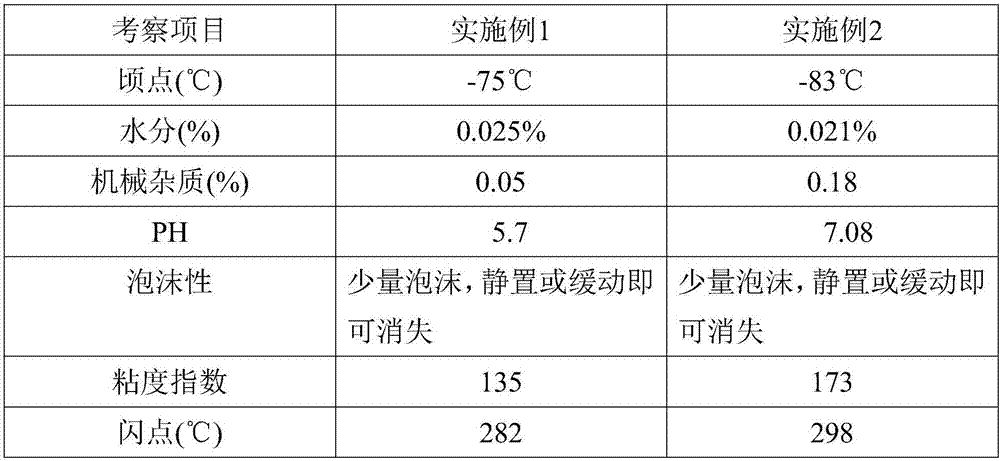

Embodiment 1

[0021] A kind of automotive air-conditioning compressor lubricating oil:

[0022] 45 parts of isopropyl acetate, 37 parts of anthracene sesame oil, 21 parts of triethylene glycol di-n-heptanoate, 18 parts of antibacterial agent, 19 parts of epoxy butyl furfurate, 39 parts of mineral oil, 27 parts of honey, carbomer 18 parts, 8015 parts of Tween, 11 parts of microcrystalline cellulose, 9 parts of gum arabic, 13 parts of garlic oil, 12 parts of ethylparaben alcohol solution, 9 parts of geranium extract, 14 parts of peanut oil, 7 parts of Keinting .

[0023] The microcrystalline cellulose is prepared from cellulose through an acidification method. The preparation method is as follows: mix the cellulose with a certain amount of deionized water, place it in an ice bath, and add concentrated sulfuric acid dropwise while stirring until 0.1mol / L, heat the mixture to 40°C, heat for 1 min, stir rapidly after reaching the temperature until the acid hydrolysis reaction for 20 min to obt...

Embodiment 2

[0034] A kind of automotive air-conditioning compressor lubricating oil:

[0035] 45 parts of isopropyl acetate, 29 parts of anthracene sesame oil, 18 parts of triethylene glycol di-n-heptanoate, 22 parts of antibacterial agent, 11 parts of epoxy butyl furfurate, 32 parts of mineral oil, 25 parts of honey, carbomer 11 parts, 8017 parts of Tween, 12 parts of microcrystalline cellulose, 8 parts of gum arabic, 13 parts of garlic oil, 17 parts of ethylparaben alcohol solution, 9 parts of geranium extract, 16 parts of peanut oil, 9 parts of Keinting .

[0036] The microcrystalline cellulose is prepared from cellulose through an acidification method. The preparation method is as follows: mix the cellulose with a certain amount of deionized water, place it in an ice bath, and add concentrated sulfuric acid dropwise while stirring until 0.5mol / L, heat the mixed solution to 60°C for 2 minutes, stir rapidly after reaching the temperature until the acid hydrolysis reaction for 20 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com