Device and method for detecting thickness of thermal barrier coating through employing laser transmission method to excite IR thermal wave

A technology of thermal barrier coating and laser transmission, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low energy density of flash lamps, unsuitable for non-contact rapid detection, poor thermal conductivity, etc., to improve the quality of laser beams, Effect of reduced thermal lens effect and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

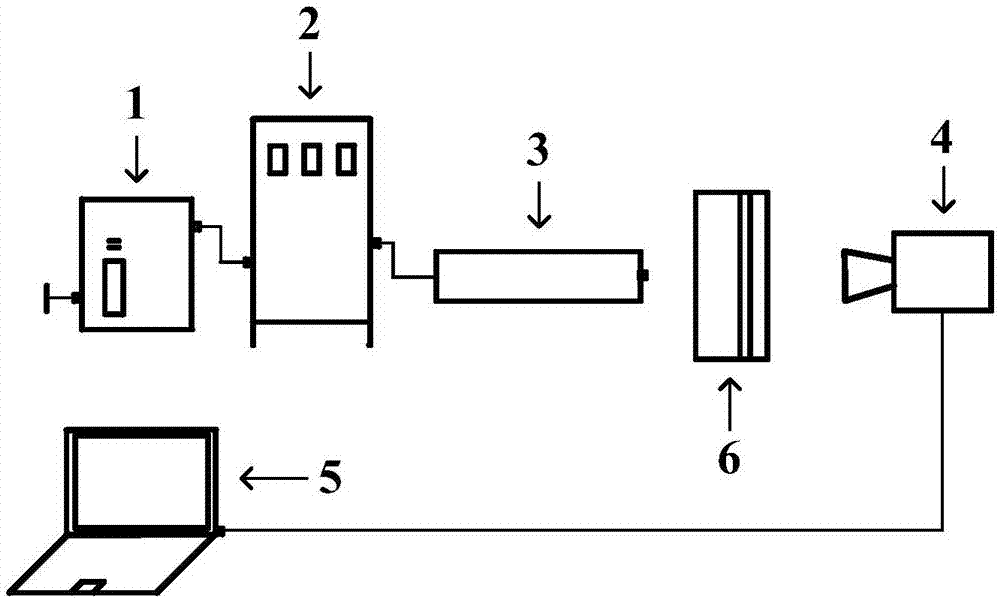

[0046] Refer to attached figure 1 , the thermal barrier coating thickness laser transmission method excitation infrared thermal wave detection device provided by the present invention includes a signal generator 1, which can output arbitrary waveforms with a frequency of 0.01 μHz to 500 KHz and sine waves with a frequency of 0.01 μHz to 15 MHz, and the number of channels is 2. The waveform vertical resolution is 16 bits; the power amplifier 2, the maximum output voltage is 400Vp-p, the maximum output current is 2Ap-p, the working frequency range is 0-7KHz, and the nonlinear distortion is 2 0 3 Stabilized ZrO 2 , the design thickness is 150μm. The base alloy is K438 nickel-based equiaxed superalloy with a thickness of 15 mm. In the working state, the pulsed laser 3 is placed on the side of the base alloy of the thermal barrier coating component 6 , and the pulsed laser 3 is connected to the output end of the signal generator 1 through the power amplifier 2 . The thermal imag...

Embodiment 2

[0056] Refer to attached figure 1 , the thermal barrier coating thickness laser transmission method excitation infrared thermal wave detection device provided by the present invention includes a signal generator 1, which can output arbitrary waveforms with a frequency of 0.01 μHz to 500 kHz and sine waves with a frequency of 0.01 μHz to 15 MHz, and the number of channels is 2. The vertical resolution of the waveform is 14 bits; power amplifier 2, the maximum output voltage is 400Vp-p, the maximum output current is 2Ap-p, the operating frequency range is 0-7KHz, and the nonlinear distortion is less than 2%; the pulse laser 3 is Semiconductor-pumped solid-state laser, the maximum power is 100W, the spot diameter is 5mm, the pulse width is adjustable from 1ms to 5s, and the wavelength is 1064nm; the infrared thermal imager 4 is an uncooled thermal imager, the image size is 160×120 pixels, and the response The wave band is 8μm-14μm, the acquisition frame frequency is 8.5Hz, and th...

Embodiment 3

[0066] Refer to attached figure 1 , the thermal barrier coating thickness laser transmission method excitation infrared thermal wave detection device provided by the present invention includes a signal generator 1, which can output arbitrary waveforms with a frequency of 0.01 μHz to 500 kHz and sine waves with a frequency of 0.01 μHz to 15 MHz, and the number of channels is 1. The vertical resolution of the waveform is 16 bits; the power amplifier 2, the maximum output voltage is 400Vp-p, the maximum output current is 1.5Ap-p, the working frequency range is 0-7KHz, the nonlinear distortion is less than 2%; the pulse laser 3, It is a semiconductor-pumped solid-state laser with a maximum power of 100W, a spot diameter of 5mm, an adjustable pulse width of 1ms to 5s, and a wavelength of 1064nm; the infrared thermal imager 4 is an uncooled thermal imager, and the image size is 160×120 pixels. The response band is 8 μm to 14 μm, the acquisition frame frequency is 8.5 Hz, and the the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spot diameter | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com