Preparation method of copper-silicon composite electrode material

A composite electrode, copper-silicon technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor cycle stability of composite materials, difficulty in suppressing the volume effect of silicon cores, and high preparation costs, and achieve improved cycle stability. The effect of improving the residual capacity and good resistance to rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

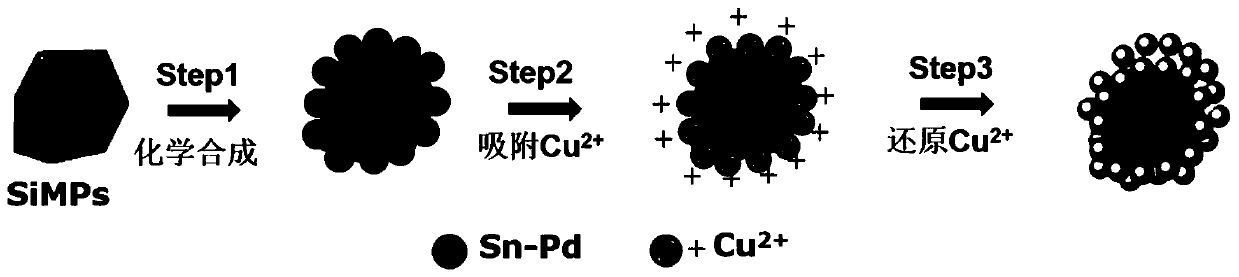

[0046](1) Disperse 0.5g of SiMPs (average particle size of 1 μm, purity of 99.9%, purchased from Aladdin Reagent Co., Ltd.) into 100mL of deionized water, and ultrasonicate for 30min to make the dispersion uniform.

[0047] (2) Add 1.6mL tris-hydrochloric acid buffer solution (1.0M, pH8.5) and 320mg dopamine hydrochloride to the solution obtained in step (1), stir and react at room temperature for 1h to make dopamine polymerize, and obtain mixture.

[0048] (3) Take 20mL of SnCl 2 Solution (SnCl 2 SnCl in solution 2 The concentration is 5g / L, and also contains 10ml / L HCl aqueous solution) was added to the mixed solution, stirred for 1h.

[0049] (4) Add 30mL PdCl 2 Solution (PdCl 2 PdCl in solution 2 The concentration is 0.5g / L, and also contains 6.25ml / L HCl aqueous solution), stirred for 1h, centrifuged to collect solid particles, and then washed 3 times with deionized water to obtain palladium-coated silicon particles.

[0050] (5) Preparation of CuSO 4 ·5H 2 O sol...

Embodiment 2

[0055] (1) Disperse 0.5g of SiMPs (average particle size of 1 μm, purity of 99.9%, purchased from Aladdin Reagent Co., Ltd.) into 100mL of deionized water, and ultrasonicate for 30min to make the dispersion uniform.

[0056] (2) Add 1.6mL tris-hydrochloric acid buffer solution (1.0M, pH8.5) and 320mg dopamine hydrochloride to the solution obtained in step (1), stir and react at room temperature for 1h to make dopamine polymerize, and obtain mixture.

[0057] (3) Take 20mL of SnCl 2 Solution (SnCl 2 SnCl in solution 2 The concentration is 5g / L, and also contains 10ml / L HCl aqueous solution) was added to the mixed solution, stirred for 1h.

[0058] (4) Add 30mL PdCl 2 Solution (PdCl 2 PdCl in solution 2 The concentration is 0.5g / L, and also contains 6.25ml / L HCl aqueous solution), stirred for 1h, centrifuged to collect solid particles, and then washed 3 times with deionized water to obtain palladium-coated silicon particles.

[0059] (5) Preparation of CuSO 4 ·5H 2 O so...

Embodiment 3

[0064] (1) Disperse 0.5g of SiMPs (average particle size of 1 μm, purity of 99.9%, purchased from Aladdin Reagent Co., Ltd.) into 100mL of deionized water, and ultrasonicate for 30min to make the dispersion uniform.

[0065] (2) Add 1.6mL tris-hydrochloric acid buffer solution (1.0M, pH8.5) and 320mg dopamine hydrochloride to the solution obtained in step (1), stir and react at room temperature for 1h to make dopamine polymerize, and obtain mixture.

[0066] (3) Take 20mL of SnCl 2 Solution (SnCl 2 SnCl in solution 2 The concentration is 5g / L, and also contains 10ml / L HCl aqueous solution) was added to the mixed solution, stirred for 1h.

[0067] (4) Add 30mL PdCl 2 Solution (PdCl 2 PdCl in solution 2 The concentration is 0.5g / L, and also contains 6.25ml / L HCl aqueous solution), stirred for 1h, centrifuged to collect solid particles, and then washed 3 times with deionized water to obtain palladium-coated silicon particles.

[0068] (5) Preparation of CuSO 4 ·5H 2 O so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com