Fluorine-containing porous carbon material as well as preparation method and application thereof

A porous carbon material and carbon dioxide technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve problems such as limited applications, and achieve the effects of low skeleton density, narrow pore size distribution, and excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

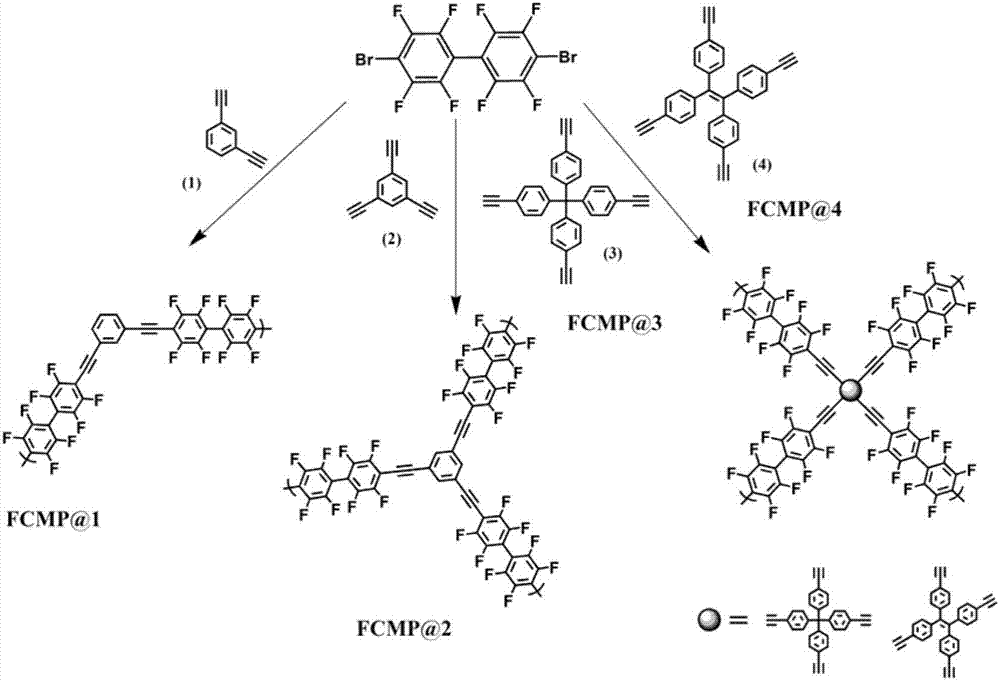

[0035] In this example, a fluorine-containing porous carbon material, the specific preparation process is: 4,4'-dibromooctafluorobiphenyl (114mg, 0.25mmol) and 1,3-diethynylbenzene monomer (47mg, 0.375mmol) Under the catalysis of tetrakis(triphenylphosphine)palladium(0), DMF and triethylamine were used as the reaction solvent, and the reaction was carried out at 120℃ for 48h under the protection of nitrogen, and the conjugated microporous polymer materials containing fluorine heteroatoms were prepared by Sonogashira coupling reaction (FCMP@1). Then, the material was calcined at 600 °C for 2 h under the protection of nitrogen to obtain a novel porous carbon material (FCMP-600@1) loaded with heteroatom fluorine.

Embodiment 2

[0037]In this example, a fluorine-containing porous carbon material, the specific preparation process is as follows: 4,4'-dibromooctafluorobiphenyl (114mg, 0.25mmol) and 1,3,5-triethynylbenzene monomer (45mg, 0.25 mmol) was catalyzed by tetrakis(triphenylphosphine)palladium(0), DMF and triethylamine were used as reaction solvents, and reacted at 120°C for 48h under nitrogen protection, and prepared conjugated microporous polymers containing fluorine heteroatoms by Sonogashira coupling reaction materials (FCMP@2). Then, the material was calcined at 600 °C for 2 h under the protection of nitrogen to obtain a novel porous carbon material (FCMP-600@2) loaded with heteroatom fluorine.

Embodiment 3

[0039] In this example, a fluorine-containing porous carbon material, the specific preparation process is: 4,4'-dibromooctafluorobiphenyl (114mg, 0.25mmol) and tetraethynylbenzenemethane monomer (78mg, 0.188mmol) in tetra( Under the catalysis of triphenylphosphine) palladium (0), DMF and triethylamine were used as the reaction solvent, and the reaction was carried out at 120 °C for 48 h under the protection of nitrogen, and the conjugated microporous polymer material containing fluorine heteroatoms (FCMP@ 3). Then, the material was calcined at 600 °C for 2 h under the protection of nitrogen to obtain a novel porous carbon material (FCMP-600@3) loaded with heteroatom fluorine.

[0040] It should be noted that the raw material tetraethynylbenzenemethane monomer used in this example is reference S1.Li, P.Z.; Wang, X.J.; Liu, J.; Lim, J.S.; Zou, R.; Zhao, Y.J.Am .Chem.Soc.,2016,138,2142-2145. Self-synthesized in the laboratory.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore size distribution | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com