Green method for recovering rare earth from waste fluorescent powder and application of green method

A fluorescent powder and rare earth technology, which is applied in the field of rare earth recovery from waste fluorescent powder, can solve the problems affecting rare earth extraction, rare earth recovery rate and purity guarantee, etc., to achieve improved leaching rate, good physical phenomena, and no acid and alkali consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

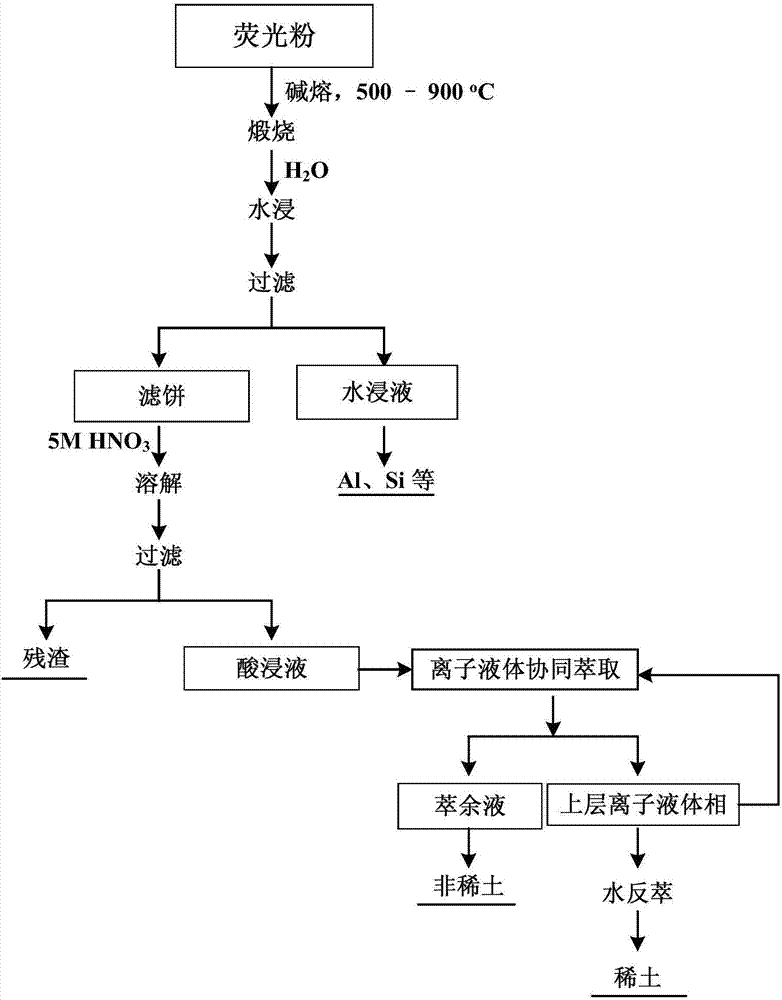

Image

Examples

Embodiment 1

[0049] A green method for recovering rare earths from waste fluorescent powder, the steps are as follows:

[0050] 1) Mix waste fluorescent powder consisting of 40wt% red powder, 25wt% blue powder, and 35wt% green powder with sodium hydroxide at a mass ratio of 1:0.3, and melt at 500°C for 3 hours to obtain an alkali melt;

[0051] 2) According to the mass ratio of 1:10, add water to the alkali melt obtained in step 1) and carry out water immersion at 80°C, and separate to obtain the water insoluble matter and water immersion liquid, according to the mass of the water insoluble matter and 2mol / L nitric acid The ratio is 1:10, adding acid to the water insoluble matter for acid leaching, and separating to obtain the acid leaching insoluble matter and acid leaching solution;

[0052] 3) Extracting the rare earth ions in the pickling solution with an extractant, the volume ratio of the extractant to the pickling solution is 1:20, the ionic strength of the water phase is 0.5mol / L, ...

Embodiment 2

[0056] A green method for recovering rare earths from waste fluorescent powder, the steps are as follows:

[0057] 1) Mix waste fluorescent powder consisting of 40wt% red powder, 25wt% blue powder, and 35wt% green powder with sodium carbonate at a mass ratio of 1:1, and melt at 900°C for 0.5h to obtain an alkali melt;

[0058] 2) According to the mass ratio of 10:1, add water to the alkali melt obtained in step 1) and carry out water immersion at 20°C, and separate to obtain the water insoluble matter and water immersion liquid, according to the mass of the water insoluble matter and 8mol / L nitric acid The ratio is 10:1, adding acid to the water insoluble matter to carry out acid leaching and separation to obtain the acid leaching insoluble matter and acid immersion liquid;

[0059] 3) Add salting-out agent sodium nitrate to the acid dipping solution to make its concentration in the feed liquid 5mol / L, and extract the rare earth ions in the pickling solution with an extractant...

Embodiment 3

[0063] A green method for recovering rare earths from waste fluorescent powder, the steps are as follows:

[0064] 1) Mix waste fluorescent powder consisting of 40wt% red powder, 25wt% blue powder, and 35wt% green powder with sodium peroxide at a mass ratio of 1:0.8, and melt at 700°C for 2 hours to obtain an alkali melt;

[0065] 2) According to the mass ratio of 1:5, add water to the alkali melt obtained in step 1) and carry out water immersion at 50°C, and separate to obtain the water insoluble matter and water immersion liquid. According to the ratio of water insoluble matter and 3mol / L nitric acid The mass ratio is 1:5, adding acid to the water-leaching insolubles for acid leaching, and separating to obtain the acid-leaching insolubles and pickling liquid;

[0066] 3) adding salting-out agent sodium nitrate to the acid dipping solution to make its concentration in the feed solution 1mol / L, and extracting the rare earth ions in the pickling solution with an extractant, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com