Optical fiber pressure sensor based on micro ellipsoidal air cavity and manufacturing method thereof

A technology of a pressure sensor and a manufacturing method, which is applied in the direction of measurement, instrumentation, and force measurement by measuring the change in optical properties of a material when it is stressed, and can solve the problem of large optical transmission loss, insufficient pressure measurement accuracy, and reflection spectrum fringes Low contrast and other issues, to achieve the effect of low cost, strong realizability, and small temperature crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

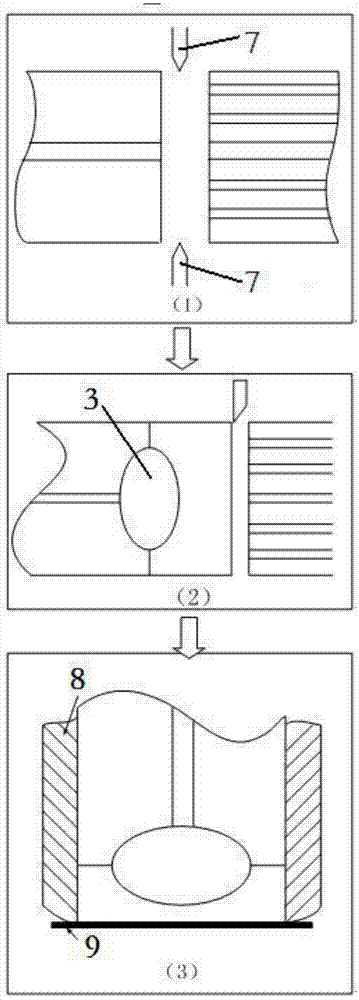

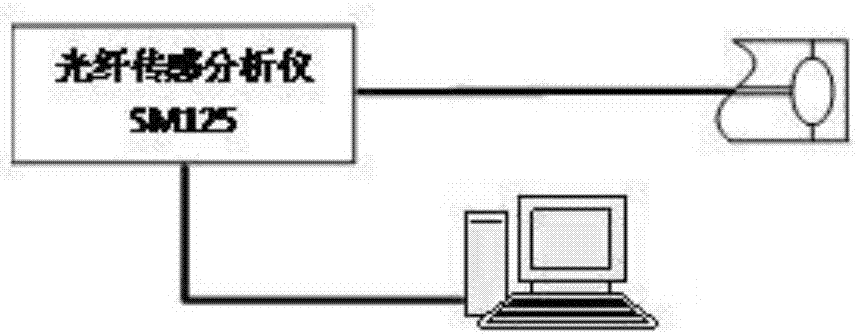

[0038] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

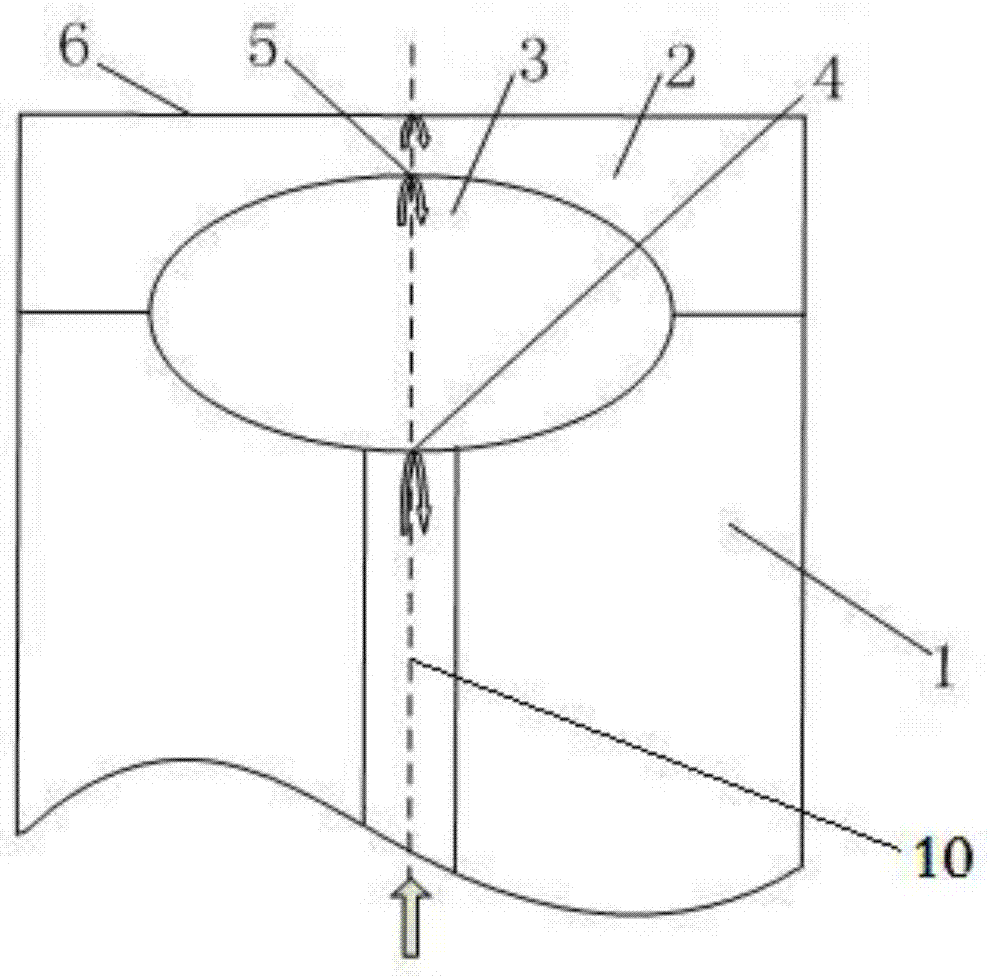

[0039] An optical fiber pressure sensor based on a micro-ellipsoid air cavity, comprising a single-mode optical fiber and a pressure-sensitive membrane; the upper end of the single-mode optical fiber is fixedly connected to the lower end of the pressure-sensitive membrane, and the connection between the single-mode optical fiber and the pressure-sensitive membrane Open the air Fabry-Perot cavity.

[0040] Further, the air Fabry-Perot cavity is a micro-ellipsoid, and the air Fabry-Perot cavity is a confocal cavity.

[0041] Further, the cavity length of the air Fabry-Perot cavity is 40 μm-50 μm.

[0042] Further, the thickness of the pressure sensitive film is 6-12 μm.

[0043] Further, the mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cavity length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com