Silicon negative electrode material and preparation method therefor, negative electrode plate and lithium ion battery

A technology of silicon negative electrode and carbon material, applied in the direction of lithium battery, negative electrode, battery electrode, etc., can solve the problems of complex production process and lack of fast charging performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

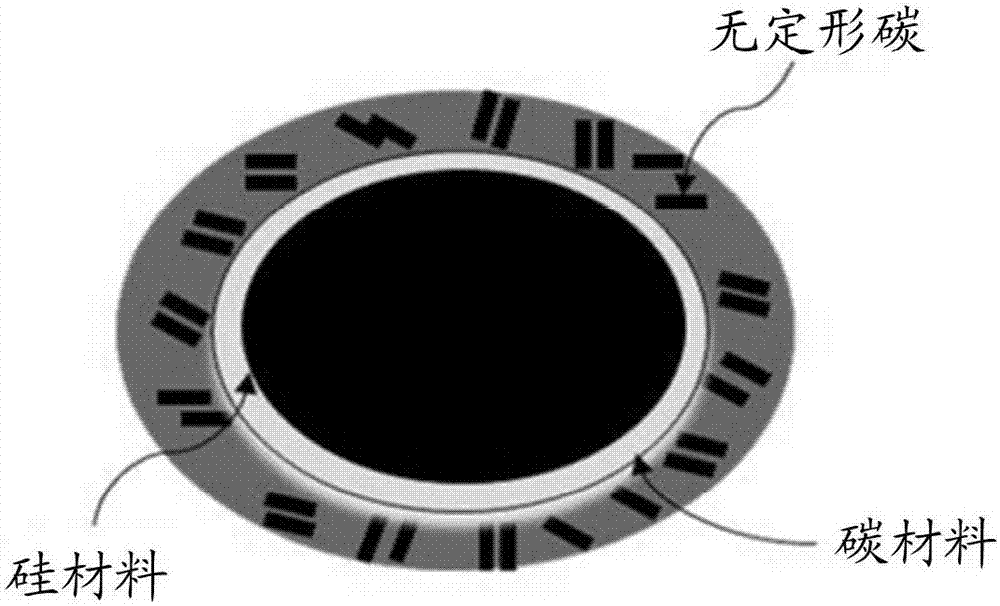

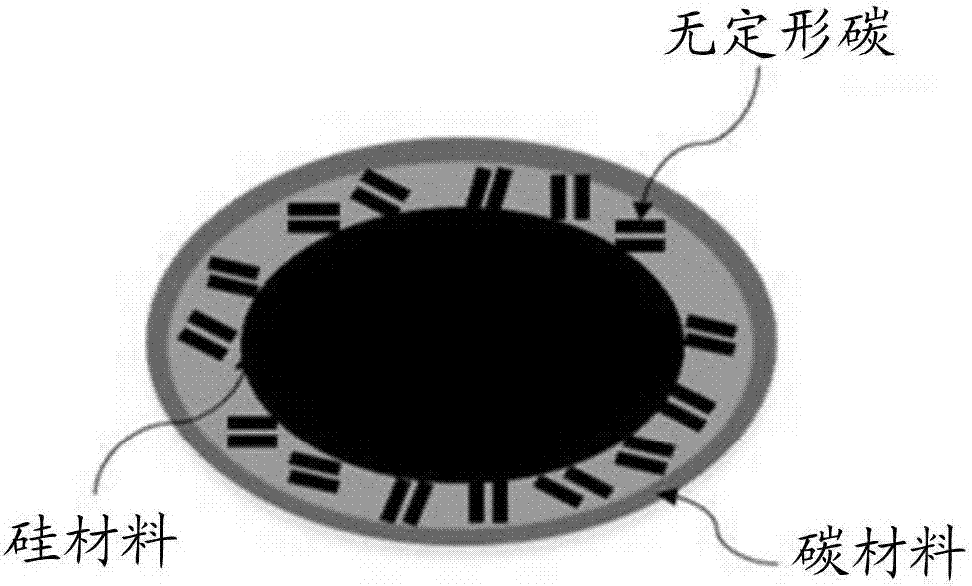

[0050] In the preparation method of the silicon negative electrode material in the embodiment of the present invention, by doping the surface of the silicon core with a carbon material, the doping elements in the carbon material are used to form lattice defects in the carbon layer, which improves the mobility of cloud electrons and reduces the lithium storage capacity. The reaction barrier increases the lithium storage binding sites, greatly increases the lithium ion migration speed, improves the lithium storage space and channels, and thus improves the fast charging performance of the silicon negative electrode material as the battery negative electrode.

[0051] It should be understood that when making the first silicon negative electrode material and the second silicon negative electrode material, the following requirements are met:

[0052] The silicon core material can be at least one of pure silicon, oxide compound silicon material, carbon compound silicon material and he...

Embodiment 1

[0060] Embodiment 1, using the silicon core as a raw material to make the silicon negative electrode material whose inner cladding layer is amorphous carbon and the outer cladding layer is N element, the specific steps are as follows:

[0061] 301. Mix 3.0kg of silicon powder with a particle size of 200nm, 0.3kg of petroleum pitch crushed to be below 0.1mm, and 0.02kg of quinoline insoluble matter, stir evenly, and put it into the reaction kettle;

[0062] 302. Heat and coat the mixture obtained in step 301 at 500°C for 2 hours, and then perform carbonization treatment at 1000°C for 4 hours under nitrogen protection;

[0063] 303. Cool the reaction product obtained in step 302 to room temperature to obtain amorphous carbon-coated silicon powder;

[0064] 304. Dissolve cetyltrimethylammonium bromide (CTAB, (C16H33)N(CH3)3Br, 0.5kg) in HCl (8L, 1mol / L) solution in an ice-water bath to obtain mixed solution A;

[0065] 305. Take 2.0 kg of the amorphous carbon-coated silicon powd...

Embodiment 2

[0069] Embodiment 2, using the silicon core as a raw material to make the silicon negative electrode material whose inner cladding layer is N element and the outer cladding layer is amorphous carbon, the specific steps are as follows:

[0070] 401. Dissolve cetyltrimethylammonium bromide (CTAB, (C16H33)N(CH3)3Br, 0.5kg) in HCl (8L, 1mol / L) solution in an ice-water bath to obtain mixed solution A;

[0071] 402. Take 2.0kg of silicon powder with a particle size of 200nm and put it into the above mixed solution A, disperse it by ultrasonic for 30 minutes, then add ammonium persulfate (APS, 0.8kg) into it, immediately form a white suspension, stir for 0.5 hours Afterwards, add pyrrole monomer (Pyrrole, 0.5 L), keep warm at 4°C for 24 hours and then filter;

[0072] 403. Wash the black precipitate obtained by filtering in step 402 with 1 mol / L HCl solution three times, and then wash with pure water until the solution is colorless and neutral, and then dry the precipitate at 80° C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com