Medical ti-based composite coating with bone repair function and antibacterial performance and preparing method of coating

A composite coating and titanium-based technology, applied in the field of medical materials, can solve problems such as insufficient bone repair ability, poor antibacterial properties, limited vascularization of implants and surrounding tissues, etc., to solve the problems of osseointegration ability and antibacterial performance Good antibacterial ability, the effect of improving osseointegration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

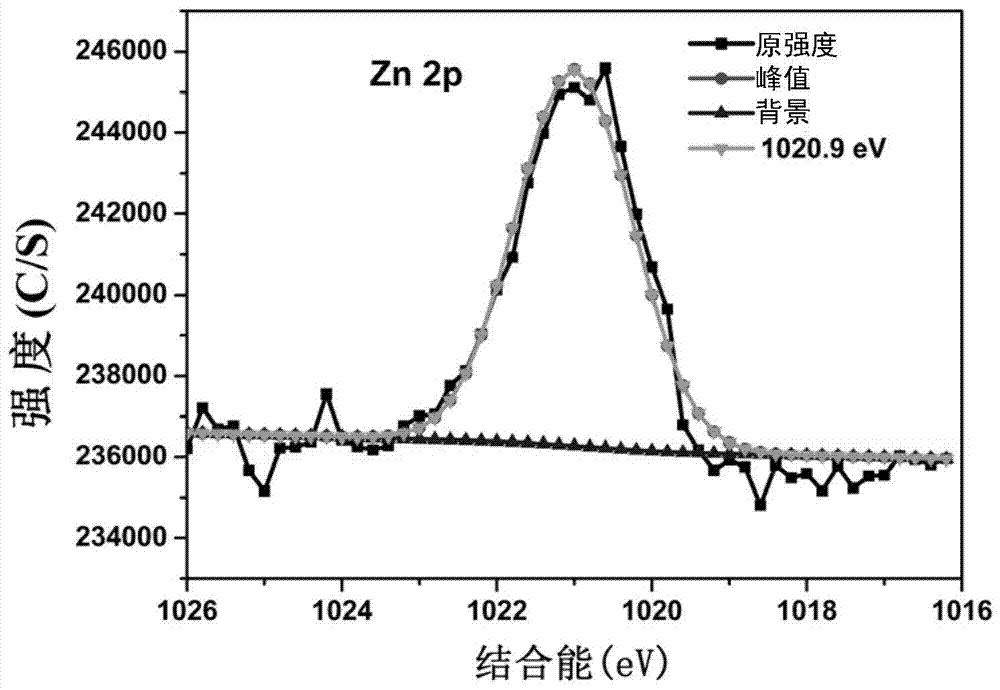

[0037] After the pure titanium sheet of 10mm×10mm×1mm is polished, it is ultrasonically cleaned with acetone, absolute ethanol and deionized water in sequence, each time for 10 minutes. Using plasma immersion ion implantation / plating technology, zinc and copper are implanted into the titanium substrate in the form of zinc-copper co-injection (Zn+Cu-PIII), and the ion implantation depth in the obtained titanium-based composite coating is 0-70nm. The atomic percentage of zinc on the titanium surface is 9.78%, and the atomic percentage of copper is 2.56%. Its concrete process parameter is shown in Table 1:

[0038] Table 1 Zinc / copper binary ion implantation parameters

[0039] Injection voltage (kV)

15

High voltage pulse width (μs)

500

Co-injection time of zinc and copper (minutes)

60

Pulse arc pulse width (μs)

800

Frequency (Hz)

5

Vacuum

5.0×10 -3

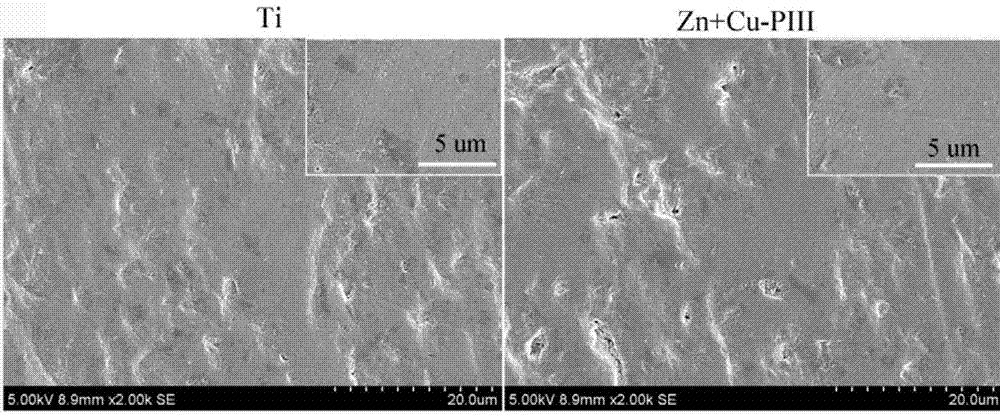

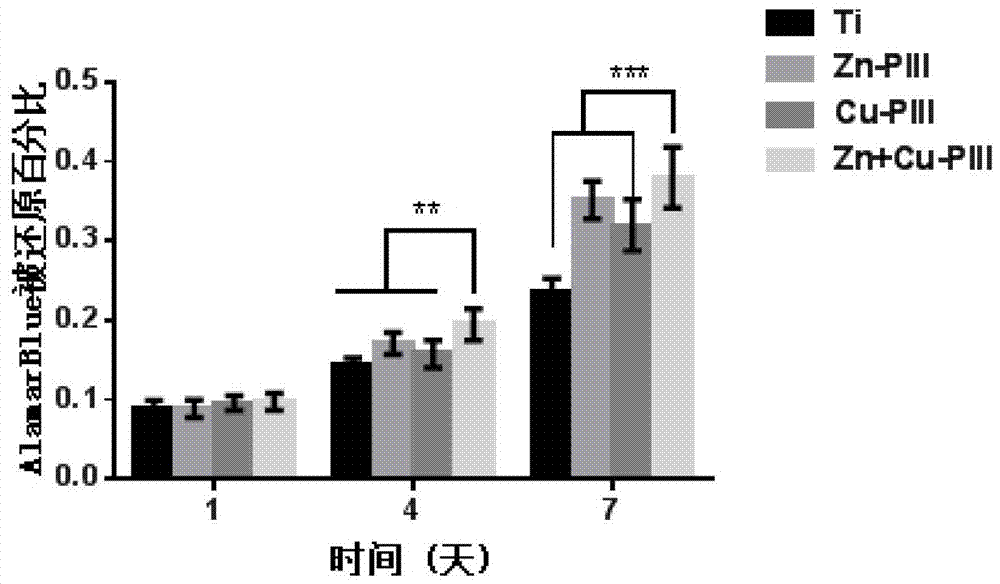

[0040] figure 1 It is a comparison diagram of the scanning electro...

Embodiment 2

[0043] After the pure titanium sheet of 10mm×10mm×1mm is polished, it is ultrasonically cleaned with acetone, absolute ethanol and deionized water in sequence, each time for 10 minutes. Using plasma immersion ion implantation / plating technology, zinc and copper are implanted into the titanium substrate in the form of zinc-copper co-injection (Zn+Cu-PIII), and the ion implantation depth in the obtained titanium-based composite coating is 0-70nm. The atomic percent of zinc on the titanium surface is 0.91%, and the atomic percent of copper is 0.04%. Its concrete process parameter is shown in Table 2:

[0044] Table 2 Zinc / copper binary ion implantation parameters

[0045]

[0046]

Embodiment 3

[0048] After the pure titanium sheet of 10mm×10mm×1mm is polished, it is ultrasonically cleaned with acetone, absolute ethanol and deionized water in sequence, each time for 10 minutes. Using plasma immersion ion implantation / coating technology, zinc and copper are implanted into the titanium substrate in the way of co-injection of copper first and then zinc (Zn+Cu-PIII), and the ion implantation depth in the obtained titanium-based composite coating is 0-100nm. The atomic percentage of zinc on the titanium surface is 26.33%, and the atomic percentage of copper is 0.01%. Its concrete process parameter is shown in Table 2:

[0049] Table 3 Zinc / copper binary ion implantation parameters

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com