Astaxanthin micro nanometer solid preparation

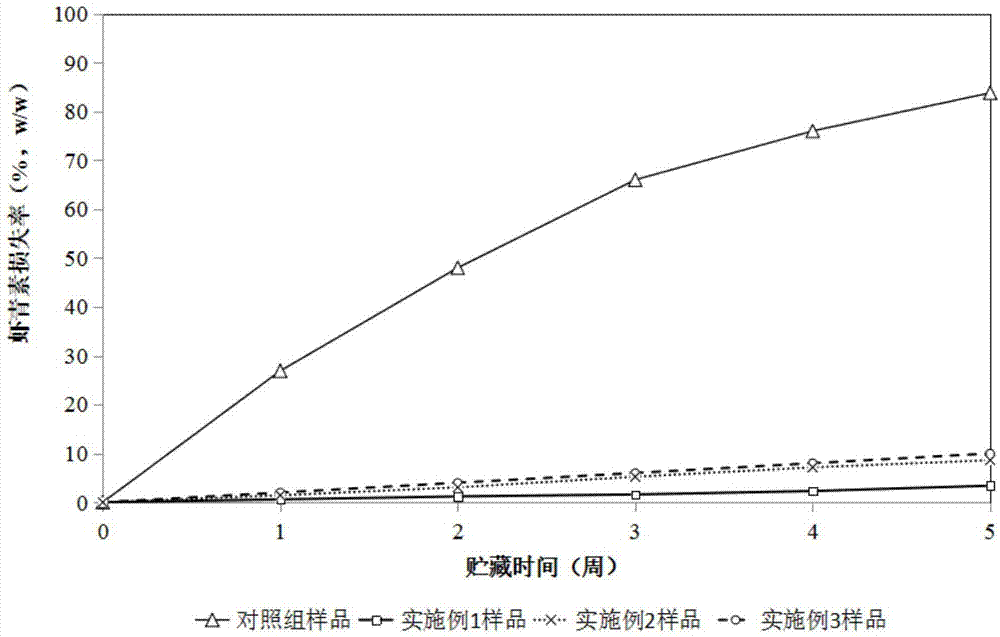

A solid preparation, astaxanthin technology, which is applied in skin care preparations, anti-inflammatory agents, anti-toxic agents, etc., can solve the problems of natural astaxanthin dosage forms such as single form, low bioavailability, and poor water dispersibility, and achieve processing And the effects of excellent storage stability, simple and mild process, and good flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

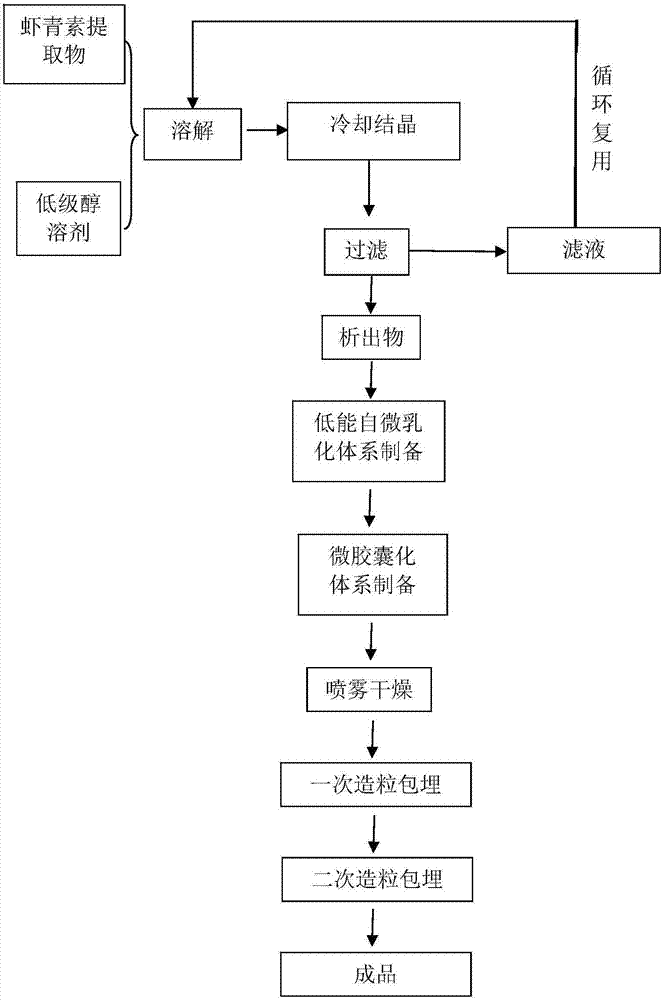

[0041] 1) Low temperature treatment of natural astaxanthin extract

[0042] Weigh 1kg of natural astaxanthin extract, add 5L of absolute ethanol, fully stir and dissolve at 60°C, then slowly cool it down to 16°C at a cooling rate of 0.5°C / min, and keep it for 3 hours, filter Collect the solid precipitate.

[0043] 2) Preparation of natural astaxanthin low-energy self-microemulsification system

[0044] The solid precipitate obtained in step 1) and 0.3 g of tocopherol were uniformly dissolved in 3 L of ethyl acetate solution at 50° C. to obtain an astaxanthin-ethyl acetate oil phase system; then 10 L of astaxanthin was added to the oil phase system Tween 80 / absolute ethanol (2:1) mixed solution was uniformly stirred for 01h under the condition of 200r / min; after the stirring was completed, it was concentrated with a rotary evaporator until no solvent flowed out, and low-energy self-microbial protein rich in natural astaxanthin was obtained. emulsifying system.

[0045] 3) Pr...

Embodiment 2

[0052] 1) Low temperature treatment of natural astaxanthin extract

[0053] Weigh 1kg of natural astaxanthin extract, add 3L of methanol, fully stir and dissolve at 65°C, then slowly cool it down to 18°C at a cooling rate of 0.8°C / min, keep it for 4 hours, and collect the solid by filtration Precipitate.

[0054] 2) Preparation of natural astaxanthin low-energy self-microemulsification system

[0055] The solid precipitate obtained in step 1) and 0.1 g of carnosic acid were uniformly dissolved in 3 L of ethyl acetate solution at 55° C. to obtain an oil phase system of astaxanthin-ethyl acetate; and then added to the oil phase system 10L of Tween 80 / absolute ethanol (2:1) mixed solution was uniformly stirred for 01h under the condition of 300r / min; after the stirring was completed, it was concentrated with a rotary evaporator until no solvent flowed out, and a low-energy self-contained product rich in natural astaxanthin was obtained. microemulsion system.

[0056] 3) Prep...

Embodiment 3

[0063] 1) Low temperature treatment of natural astaxanthin extract

[0064] Weigh 1kg of natural astaxanthin extract, add 4L of n-butanol, fully stir and dissolve at 60°C, then slowly cool it down to 14°C at a cooling rate of 1°C / min, and keep it for 2 hours, filter Collect the solid precipitate.

[0065] 2) Preparation of natural astaxanthin low-energy self-microemulsification system

[0066] Dissolve the solid precipitate obtained in step 1) and 0.5g of coenzyme Q in 3L of ethyl acetate solution at 60°C to obtain an astaxanthin-ethyl acetate oil phase system; then add 10L of Tween 80 / absolute ethanol (2:1) mixed solution was uniformly stirred for 01h under the condition of 200r / min; after the stirring was completed, it was concentrated with a rotary evaporator until no solvent flowed out, and low-energy self-microbial protein rich in natural astaxanthin was obtained. emulsifying system.

[0067] 3) Preparation of natural astaxanthin microencapsulation system

[0068] Mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com