Activated carbon preparation method and activated carbon

An activated carbon, protective gas technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of environmental pollution, non-renewable resources, etc., achieve large specific surface area, reduce preparation costs, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of activated carbon and the activated carbon will be further described in detail in combination with specific embodiments below.

[0030] The preparation method of the gac of an embodiment, comprises the following steps:

[0031] Step S110 , carbonizing the straw at 300° C. to 400° C. under a protective gas atmosphere to obtain carbides.

[0032] In one embodiment, the stalks are corn stalks. Of course, in other embodiments, the straw can also be the remaining part of wheat, rice, potatoes, rapeseed, cotton, sugar cane or other coarse grain crops after the seeds are harvested.

[0033] In one embodiment, the straw is crushed, and the crushed straw is carbonized at 300° C. to 400° C. to obtain carbides. Preferably, the straw is pulverized to a particle size of 10 microns to 30 microns.

[0034] In one embodiment, the protective gas is selected from at least one of nitrogen, argon and helium.

[0035] In one embodiment, the straw is placed in a ...

Embodiment 1

[0065] The preparation of activated carbon comprises the following steps:

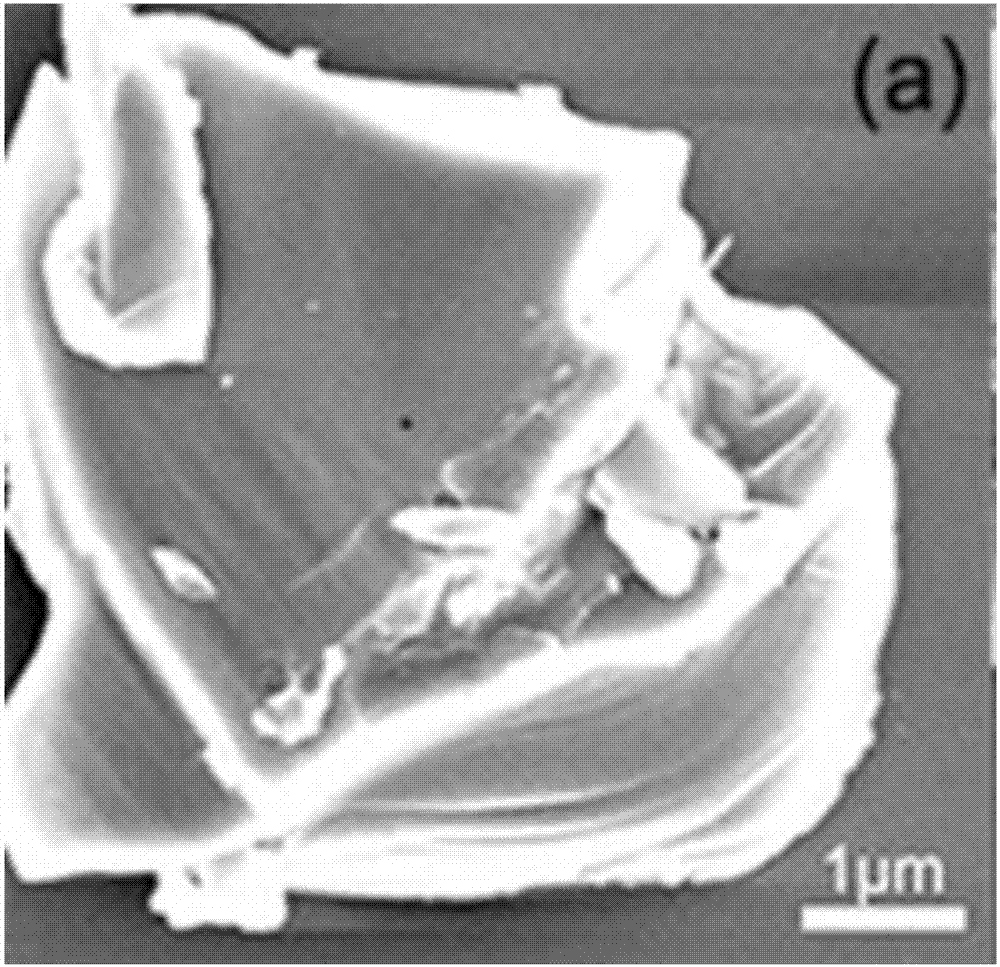

[0066] (1) Put 2 grams of crushed corn stalk cores in a tube furnace, and carry out carbonization at 350° C. under the protection of nitrogen to obtain 0.4 g of carbides, and the carbonization time is 3 hours;

[0067] (2) the carbide obtained in step (1) is placed in an agate mortar and ground for 0.5 hour to grind evenly, and the carbide by mass ratio: KOH=1:3 takes by weighing potassium hydroxide 1.2g and mixes with the carbide to obtain a mixture;

[0068] (3) Move the mixture in step (2) to a tube furnace, heat the mixture to 700° C. at a heating rate of 5° C. / min under nitrogen protection, and hold the temperature for 1 hour to obtain a pre-product;

[0069] (4) After the pre-product prepared by step (3) is placed in an agate mortar and ground for 0.5 hours, it is mixed with 40 mL of 2mol / L hydrochloric acid, bathed in water for 1 hour at 90° C., and the filter residue obtained after filtration i...

Embodiment 2

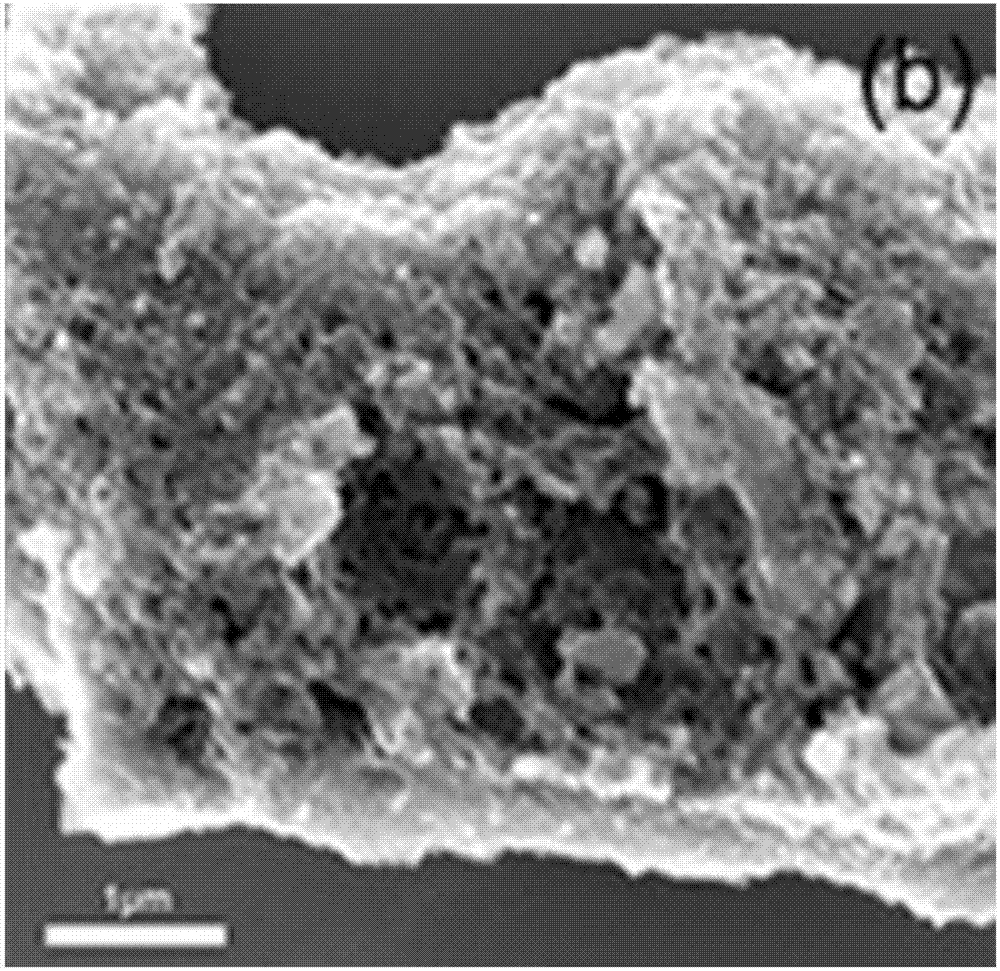

[0075] (1) Put 1 gram of crushed corn stalks in a tube furnace, and carbonize at 300° C. to obtain 0.2 g of carbides, and the carbonization time is 2 hours;

[0076] (2) Place the carbide obtained in step (1) in an agate mortar and grind for 1 hour to grind evenly, get 0.6g of potassium hydroxide by mass ratio carbide: KOH=1:3 and mix with carbide to obtain a mixture;

[0077] (3) Move the mixture in step (2) to a tube furnace, heat the mixture to 500° C. at a heating rate of 5° C. / min under nitrogen protection, and hold the temperature for 1 hour to obtain a pre-product;

[0078] (4) After the pre-product prepared in step (3) is placed in an agate mortar and ground for 1 hour, it is mixed with 40 mL of 1mol / L hydrochloric acid, and water bathed for 1 hour at 80° C., and the filter residue obtained after filtration is washed with deionized water until Neutral, and dry at 60 ° C for 12 hours, you can get the amorphous activated carbon material.

[0079] The specific surface ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com