Method for preparing arsenic-containing cured glass by arsenic-containing waste slag

A technology of waste slag and glass, which is applied in the field of preparing arsenic-containing solidified glass to achieve the effects of high hardness, energy saving, and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

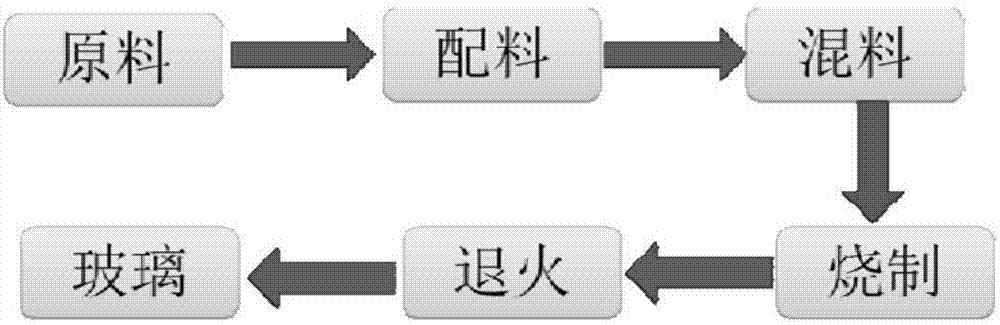

Method used

Image

Examples

Embodiment 1

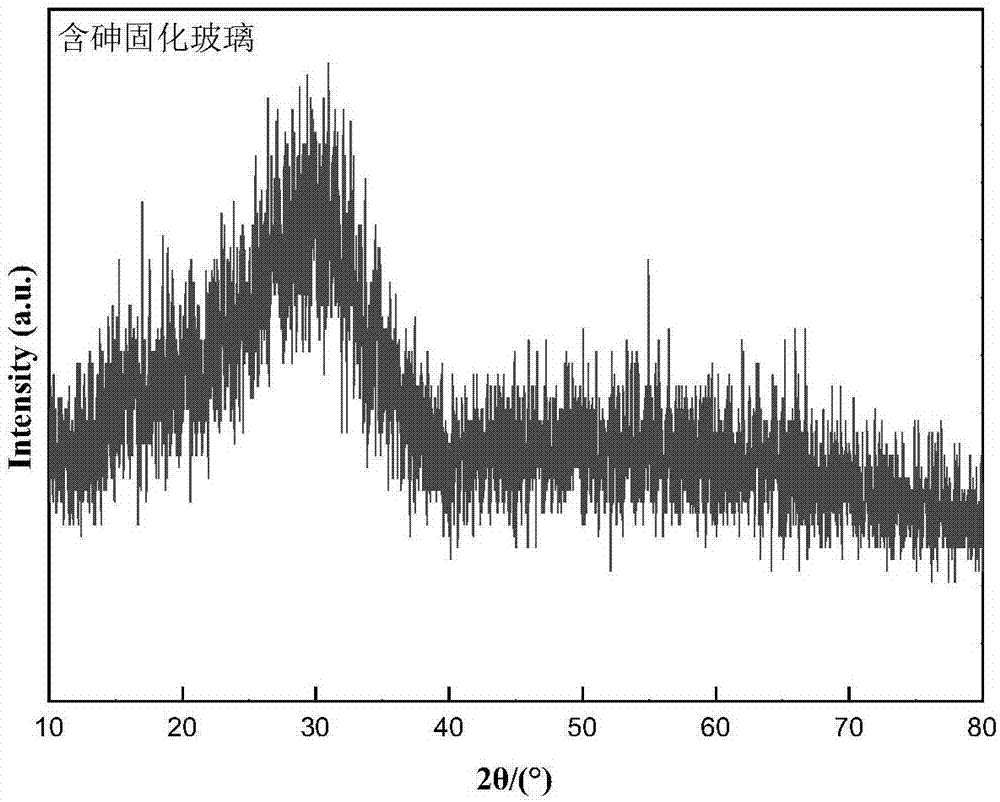

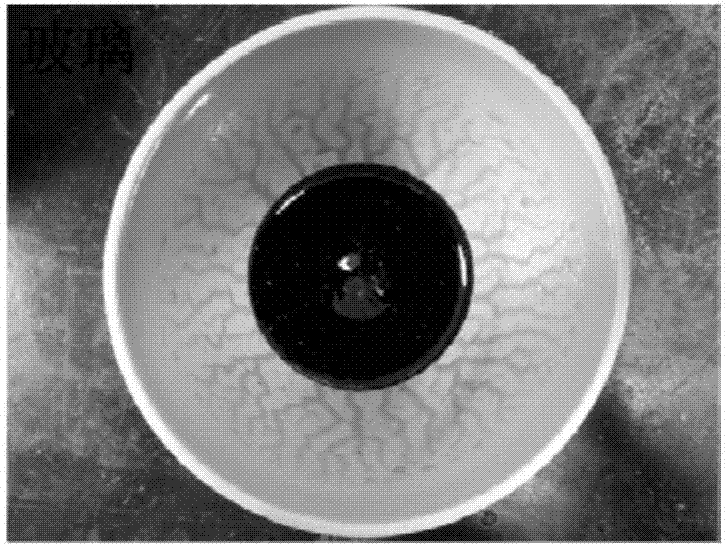

[0024] Copper smelting slag, arsenic-containing waste slag, silicon-based materials and boric acid are used as raw materials, and the compositions of arsenic-containing waste slag, copper smelting slag and silicon-based materials are shown in the table below. Copper smelting slag, arsenic-containing waste slag, silicon-based materials and boric acid were ball-milled for 1 hour according to the mass ratio of 40:20:31:9, passed through 150 mesh and placed in a ceramic crucible, and the ceramic crucible was placed in a muffle furnace. Fire in an air atmosphere, keep the heating rate at 10°C / min to 1100°C, and keep it warm for 1h. After the reaction is over, the ceramic crucible is taken out and cooled in air to obtain arsenic-containing solidified glass. X-ray diffraction analysis was performed on the synthesized glass material, and the results are shown in the figure; at the same time, the leaching characteristics and compressive strength were tested using the American TCLP meth...

Embodiment 2

[0034] Copper smelting slag, arsenic-containing waste slag, silicon-based materials and boric acid are used as raw materials, and the compositions of arsenic-containing waste slag, copper smelting slag and silicon-based materials are shown in the table below. Copper smelting slag, arsenic-containing waste slag, silicon-based materials, and boric acid were ball-milled for 1 hour according to the mass ratio of 31:27:33:9, and the raw materials over 200 mesh were placed in a ceramic crucible, and the ceramic crucible was placed in a muffle furnace Fire in an air atmosphere, keep the heating rate from 10°C / min to 1150°C, and keep it warm for 1.5h. After the reaction is over, the ceramic crucible is taken out and placed in water for cooling to obtain arsenic-containing solidified glass. Meanwhile, US TCLP method and GB_T17671-1999 cement mortar strength testing method were used to test the leaching characteristics and compressive strength, and the results are shown in the table bel...

Embodiment 3

[0044] Copper smelting slag, arsenic-containing waste slag, silicon-based materials and boric acid are used as raw materials, and the compositions of arsenic-containing waste slag, copper smelting slag and silicon-based materials are shown in the table below. Copper smelting slag, arsenic-containing waste slag, silicon-based materials, and boric acid are ball-milled for 1 hour according to the mass ratio of 44:18:28:10, and the raw materials over 300 mesh are placed in a corundum crucible, and the corundum crucible is placed in a muffle furnace Fire in an air atmosphere, keep the heating rate from 10°C / min to 1100°C, and keep it warm for 1h. After the reaction, the ceramic crucible was taken out and cooled in liquid nitrogen to obtain arsenic-containing solidified glass. Meanwhile, US TCLP method and GB_T17671-1999 cement mortar strength testing method were used to test the leaching characteristics and compressive strength, and the results are shown in the table below.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com