Method for preparing organic fertilizer by bean meal microbial fermentation and application of method

A technology of microbial fermentation and organic fertilizer, applied in the field of organic fertilizer, can solve the problem that organic fertilizer can not satisfy organic crops well, and achieve the effects of effective control of growth, rapid fruit expansion and significant yield increase effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

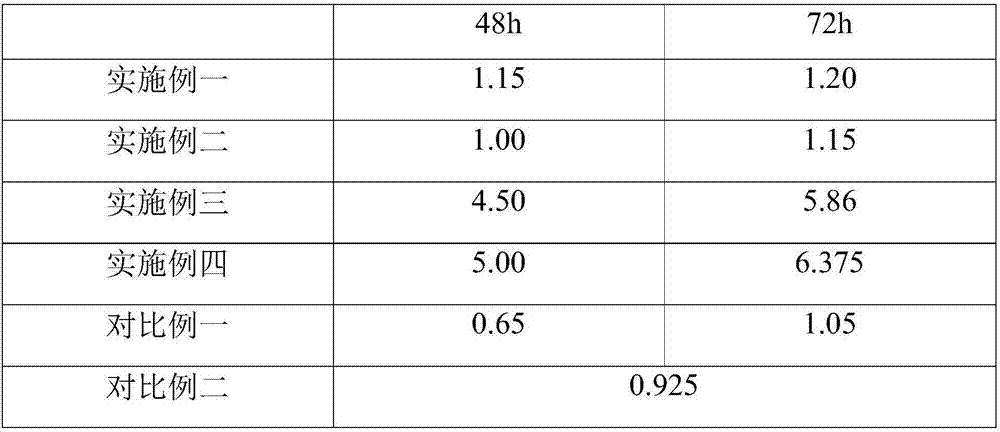

Examples

preparation example Construction

[0032] Preferably, the fermented strains include a first fermented strain and a second fermented strain, the raw material components of the first fermented strain include actinomycetes and Bacillus subtilis, and the raw material components of the second fermented strain include yeast. Wherein, the preparation method of the first fermentation strain includes: S201: Inoculate actinomycetes and Bacillus subtilis into sterilized soybean meal, and make the content of Bacillus subtilis be (3~6)×10 6 cfu / mL, the content of actinomycetes is (1~3)×10 5cfu / m, and then carry out the first-generation culture; wherein, the temperature of the first-generation culture is 25°C-30°C, and the time is 5h-8h; S202: Inoculate the product after the first-generation culture in S201 into the sterilized In the soybean meal, the second-generation culture is then carried out; wherein, the inoculum amount of the product after the first-generation culture is 1% to 2%, the temperature of the second-generat...

Embodiment 1

[0037] The invention provides a method for preparing organic fertilizer by microbial fermentation of soybean meal, comprising the following steps:

[0038] S101: Mix the soybean meal and water evenly according to the material-water ratio of 1:1.5, and then add the first fermentation strain and the second fermentation strain for fermentation; wherein, the amount of the fermentation strain is 1% of the mass of the soybean meal, and the second The mass of the first starter and the first starter is 1:10; the fermentation is aerobic fermentation of bar piles, and the time is 72 hours, and the piles are turned once during the fermentation process.

[0039] The fermented strains include first fermented strains and second fermented strains, the raw material components of the first fermented strains include actinomycetes and bacillus subtilis, and the raw material components of the second fermented strains include yeast. The preparation method of the first fermentation strain includes:...

Embodiment 2

[0042] The invention provides a method for preparing organic fertilizer by microbial fermentation of soybean meal, comprising the following steps:

[0043] S101: Mix the soybean meal and water evenly according to the material-to-water ratio of 1:1, and then add the first fermentation strain and the second fermentation strain to ferment; wherein, the added amount of the fermentation strain is 2% of the mass of the soybean meal, and the second The mass of the first starter and the first starter is 1:5; the fermentation is bar pile aerobic fermentation, the time is 100h, and the pile is turned once during the fermentation process.

[0044] The fermented strains include first fermented strains and second fermented strains, the raw material components of the first fermented strains include actinomycetes and bacillus subtilis, and the raw material components of the second fermented strains include yeast. The preparation method of the first fermentation strain includes: S201: inocula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com