Triarrhena lutarioriparia based modified charcoal preparation method, triarrhena lutarioriparia based modified charcoal and application

A biochar and modification technology, applied in chemical instruments and methods, restoration of polluted soil, other chemical processes, etc., can solve problems that have not yet been reported in research, and achieve the effect of rich pore structure and high adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

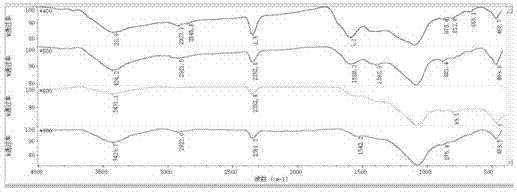

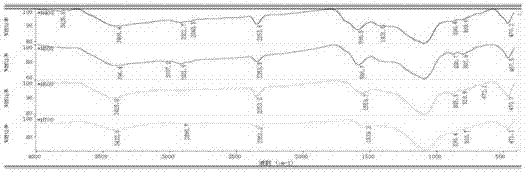

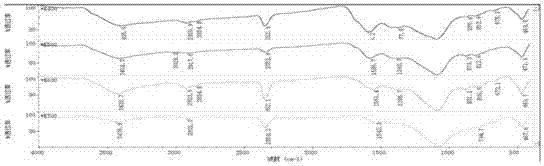

Image

Examples

Embodiment 1

[0032] The preparation method of Nandi-based modified biochar, specifically, the method includes the following steps:

[0033] (1) Preparation of Nandi-based biochar: clean Nandi (collected from Miscanthus Plant Resource Nursery of Hunan Agricultural University), bake at 70°C for 4h, take out and cool, cut into 2cm sections and smash into powder, take 10g of the Nandi powder in The crucible is placed in a vacuum atmosphere furnace, carbonized at 400°C for 2 hours and then cooled to obtain biochar;

[0034] (2) Nandi-based biochar treatment: weigh 0.5g of the biochar described in step (1) into a 100mL beaker, add 60mL of 1mol / L HCl and soak for 12h, wash the soaked biochar with distilled water at 2h intervals Second, then suction filtration, drying at 70°C, weighing, grinding and sieving to obtain acid-treated biochar;

[0035] (3) Nandi-based biochar alkali treatment: weigh 0.5g of the acid-treated biochar in step (2) into a 100mL beaker, add 0.4g (that is, the mass of the acid-trea...

Embodiment 2

[0039] The preparation method of Nandi-based modified biochar, specifically, the method includes the following steps:

[0040] (1) Preparation of Nandi-based biochar: Wash Nandi (collected from Miscanthus Plant Resource Nursery of Hunan Agricultural University), bake at 90°C for 6h, take out and cool, cut into 10cm sections and smash into powder, take 80g of the Nandi powder in The crucible is placed in a vacuum atmosphere furnace, carbonized at 700°C for 2 hours and then cooled to obtain biochar;

[0041] (2) Nandi-based biochar treatment: weigh 0.5g of the biochar described in step (1) into a 100mL beaker, add 60mL1mol / L HCl soak for 12h, wash the soaked biochar twice with distilled water at 4h intervals Second, then suction filtration, drying at 90°C, weighing, grinding and sieving to obtain acid-treated biochar;

[0042] (3) Nandi-based biochar alkali treatment: weigh 0.5g of the acid-treated biochar in step (2) into a 100mL beaker, add 0.6g (that is, the mass of the acid-treate...

Embodiment 3

[0046] The preparation method of Nandi-based modified biochar, specifically, the method includes the following steps:

[0047] (1) Preparation of Nandi-based biochar: Clean Nandi (collected from Miscanthus Plant Resource Nursery of Hunan Agricultural University), bake at 80°C for 5h, take out and cool, cut into 4cm sections and smash into powder, take 30g of the Nandi powder in The crucible is placed in a vacuum atmosphere furnace, carbonized at 500°C for 2 hours and then cooled to obtain biochar;

[0048] (2) Nandi-based biochar treatment: Weigh 0.5g of the biochar described in step (1) into a 100mL beaker, add 60mL of 1mol / L HCl to soak for 12h, and wash the soaked biochar with distilled water at intervals of 3h. Second, then suction filtration, drying at 80°C, weighing, grinding, sieving to obtain acid-treated biochar;

[0049] (3) Nandi-based biochar alkali treatment: weigh 0.5g of the acid-treated biochar in step (2) into a 100mL beaker, add 0.5g (that is, the mass of the acid-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com