A kind of green high-efficiency palladium magnetic adsorbent preparation method and application

A magnetic adsorbent, high-efficiency technology, applied in the direction of chemical instruments and methods, adsorption water/sewage treatment, process efficiency improvement, etc., can solve the problems of secondary damage to the environment, complex production process, complex preparation process, etc., and achieve adsorption efficiency High, reduce production cost, simplify the effect of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

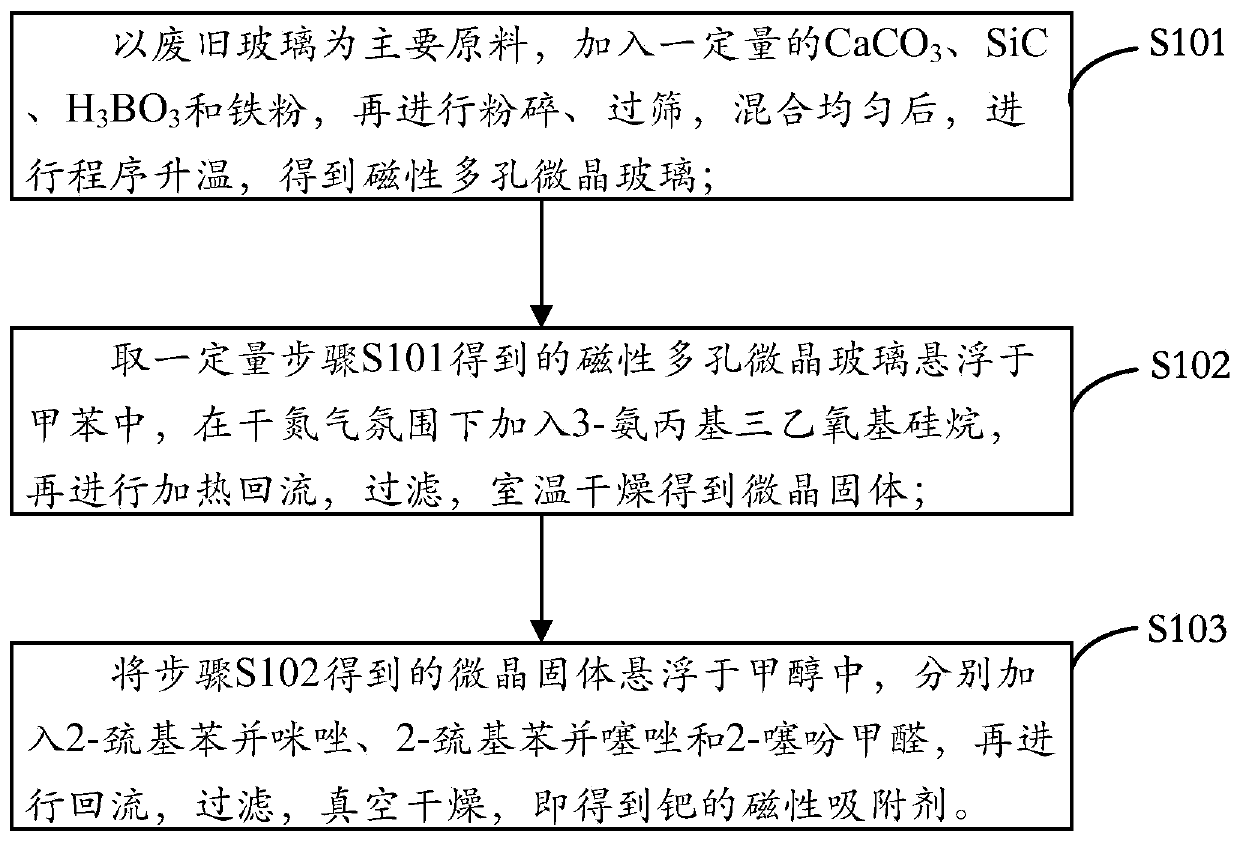

[0030] The preparation method of the invention is divided into two parts: preparation of magnetic porous glass-ceramics and loading of organic functional groups. Firstly, the magnetic porous glass-ceramic is prepared by temperature programming method, and secondly, organic functional groups are loaded by two-step loading method, and the obtained adsorbent is a high-efficiency specific magnetic adsorbent for palladium. see figure 1 , the preparation method of the green high-efficiency palladium magnetic adsorbent of the present invention specifically comprises the following steps:

[0031] Step S101, using waste glass as the main raw material, adding a certain amount of CaCO 3 , SiC, H 3 BO 3 and iron powder, then pulverized, sieved, mixed evenly, and then programmed to heat up to obtain magnetic porous glass-ceramics.

[0032] Porous glass-ceramics is a microcrystalline material containing closed pores or connected pores obtained by heat treatment of inorganic amorphous ma...

Embodiment 1

[0050] The preparation method of the high-efficiency specific magnetic adsorbent of palladium, using waste door and window glass as raw material, comprises the following processes:

[0051] (1) Preparation of magnetic porous glass-ceramics

[0052] Magnetic porous glass-ceramic was prepared by temperature programming method. First, grind and sieve the waste glass, and weigh the waste glass, CaCO 3 , SiC, H 3 BO 3 and iron powder. After mixing evenly, put it into the muffle furnace and carry out temperature programming. Raise to 800°C at a rate of 20°C / min, hold for 30 minutes, then rise to 1133°C at a rate of 20°C / min, and hold for 10 minutes to obtain magnetic porous glass-ceramics.

[0053] (2) Loading of organic functional groups

[0054] Suspend 2g of the above-mentioned magnetic porous glass-ceramics in 70mL of dry toluene, stir for 1 hour, add 1g of 3-aminopropyltriethoxysilane under a dry nitrogen atmosphere, heat and reflux for 12 hours, filter, ethanol or dichlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com