Combined machining system utilizing ultrashort pulse lasers

An ultra-short pulse laser and composite processing technology, which is used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of not being able to take into account accuracy and efficiency at the same time, achieve high processing accuracy, improve processing accuracy, and eliminate cut surface burrs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

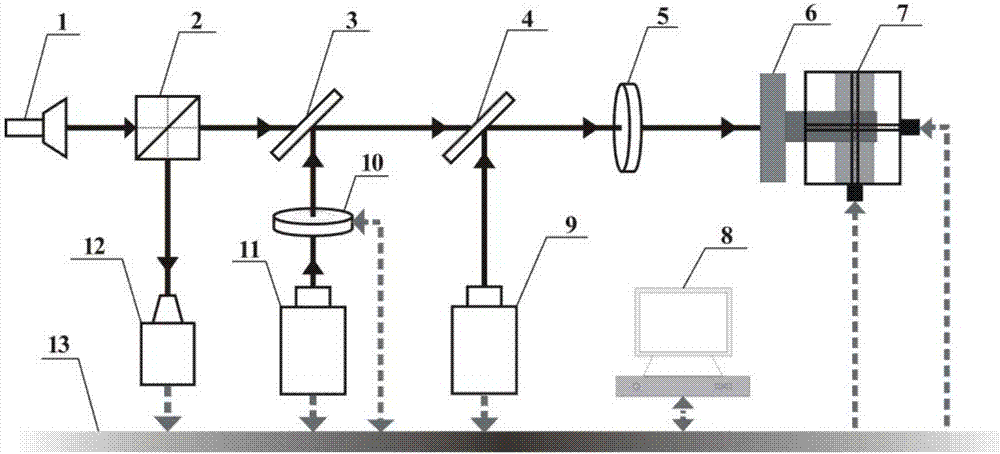

[0022] A compound processing system using ultrashort pulse laser of the present invention is shown in the figure figure 1 As shown, the illumination light emitted by the illumination source 1 passes through the dichroic prism 2 and irradiates to the first dichroic mirror 3, and the illumination light sequentially passes through the first dichroic mirror 3 and the second dichroic mirror 4, and then passes through the focusing lens 5 to irradiate on the fixed two-dimensional moving Processed sample 8 on stage 7.

[0023] The illuminating light reflected back from the surface of the processed sample 6 is reflected to the CCD image detector 12 through the second dichroic mirror 4, the first dichroic mirror 3, and the dichroic prism 2, and is used to monitor the microstructure of the processed sample surface. The image displayed on the sample surface is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com