Leather tanning agent and preparation method thereof

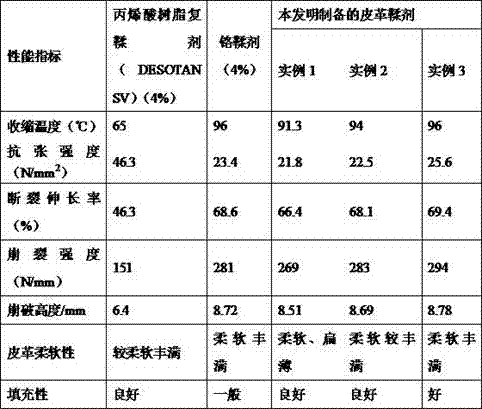

A technology for tanning agent and leather, applied in the field of leather tanning agent and its preparation, can solve the problems of rough grain surface and hard body of finished leather, and achieve the effects of improving filling performance, increasing shrinkage temperature, and soft and plump hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Take 20g of polyether diol with a molecular weight of 1000 and 300mL of toluene into a three-necked flask equipped with a thermometer and a reflux device, then add 50g of acrylic acid, and move the three-necked flask into a digital speed measuring constant temperature magnetic stirrer. , at a speed of 300r / min, stir and mix for 3min, then add 0.1mL sulfuric acid solution with a mass fraction of 96%, keep warm and stir for 3h, after the reaction is over, put the product in a rotary evaporator and concentrate for 30min , to obtain a concentrated solution, add the concentrated solution and 200mL water into a three-necked flask with a thermometer and a reflux device, place the flask in a water bath, control the temperature of the water bath to 60°C, and then add 50g of methacrylic acid and 0.1g sodium persulfate, heat preservation and stirring reaction 60min, obtain polyether glycol branched acrylic resin, finally by weight, get 30 parts of polyether glycol branched acrylic ...

example 2

[0024] Take 20g of polyether diol with a molecular weight of 1000 and 300mL of toluene into a three-necked flask equipped with a thermometer and a reflux device, then add 50g of acrylic acid, and move the three-necked flask into a digital speed measuring constant temperature magnetic stirrer. , at a speed of 300r / min, stir and mix for 3min, then add 0.1mL sulfuric acid solution with a mass fraction of 96%, keep warm and stir for 3h, after the reaction is over, put the product in a rotary evaporator and concentrate for 30min , to obtain a concentrated solution, add the concentrated solution and 200mL water into a three-necked flask with a thermometer and a reflux device, place the flask in a water bath, control the temperature of the water bath to 60°C, and then add 50g of methacrylic acid and 0.1g lauroyl peroxide, insulated and stirred for 60 minutes to obtain a polyether glycol branched acrylic resin, and graphite oxide was added to a freeze pulverizer to pulverize, and passe...

example 3

[0026]Take 30g of polyether diol with a molecular weight of 1000 and 400mL of toluene into a three-necked flask equipped with a thermometer and a reflux device, then add 60g of acrylic acid, and move the three-necked flask into a digital speed measuring constant temperature magnetic stirrer. , under the condition that the rotating speed is 400r / min, after stirring and mixing for 5min, add 0.3mL sulfuric acid solution with a mass fraction of 96%, and keep stirring for 4h. , to obtain a concentrated solution, add the concentrated solution and 300mL water into a three-necked flask with a thermometer and a reflux device, place the flask in a water bath, control the temperature of the water bath to 70°C, and then add 60g of methacrylic acid and 0.3g potassium persulfate, insulated stirring reaction 90min, obtains polyether glycol branched acrylic resin, graphite oxide is added in the freezing pulverizer and pulverizes, and crosses 100 mesh sieves, obtains graphite oxide powder, gets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com