A continuous centrifugal electrochemical reaction device and its operation method and application

A technology of electrochemical reaction and centrifugal pump, which is applied in the field of electrochemical reaction, can solve the problems of slow progress in the industrialization of the new centrifugal enhanced electrochemical method, and achieve the effects of industrial upgrading, accelerated rate and efficiency, and enhanced mass transfer of metal ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

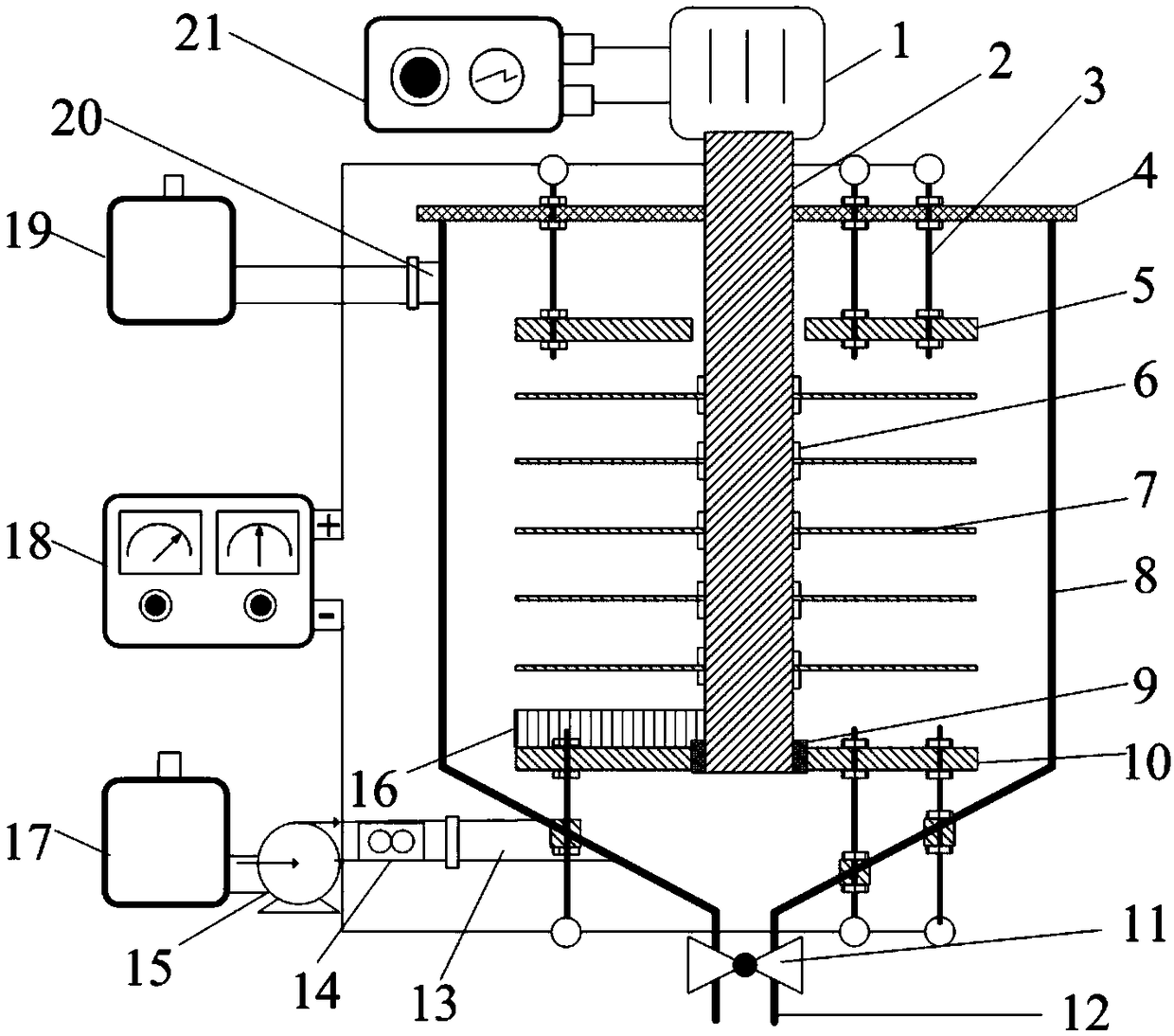

[0042] Continuous centrifugal electrochemical reaction device see figure 1 , the upper electrode 5 is fixed on the bottom of the electrolytic cell cover 4 through a hard copper wire, and the electrolytic cell cover 4 is a detachable structure; the lower electrode 10 is fixed on the bottom of the electrolytic cell body 8 through a hard copper wire; Fasteners are equidistantly fixed on the rotating shaft 2, and the middle electrode 7 and the upper and lower end electrodes 5, 10 form a disk electrode group.

[0043] The motor 1 drives the rotating shaft 2 to rotate. The display and adjustment of the rotating speed of the rotating shaft 2 are controlled by the motor controller 21. The rotating shaft 2 drives the high-speed rotation of the middle electrode 7 to form a centrifugal field at the interface micro-area between the electrode and the solution. The intensity of the centrifugal field is controlled by the motor 1. Speed regulation.

[0044] The positive and negative poles ...

Embodiment 2

[0048] The electrolytic cell of the continuous centrifugal electrochemical reaction device is made of polytetrafluoroethylene, the inner diameter is 300mm, the height is 400mm, the number of intermediate electrode sheets is 3, the diameter of the electrode plate is 200mm, the electrode spacing is 50mm, and the electrode is single-sided A titanium electrode with a noble metal coating, the side with the coating is the anode, and the side without the coating is the cathode. Turn on the centrifugal pump 15 before electrolysis to input the raw electrolytic solution into the reaction device. When the device is filled with electrolyte, turn on the motor 1 to rotate to drive the rotation of the intermediate electrode 7, adjust the rotation speed of the rotating shaft 2, and turn on the rectifier 18 at the same time to perform electrochemical reactions. It flows out from the overflow port 20 at the upper part of the shell, and the powdery electrolytic product is discharged from the disc...

Embodiment 3

[0050] Using the same device and operation method as in Example 2, for a 5g / L copper-containing solution, when the rotating shaft does not rotate, the current efficiency of the electrolytic copper is 32.1%, and the recovery rate of copper in the solution is 43%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com