Graphene thermal-conductive coating modified radiator and preparation method thereof

A thermal conductive coating, graphene technology, applied in graphene, chemical instruments and methods, coatings, etc., can solve problems such as performance bottlenecks, and achieve the effects of high production efficiency, rich raw material sources, and improved bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

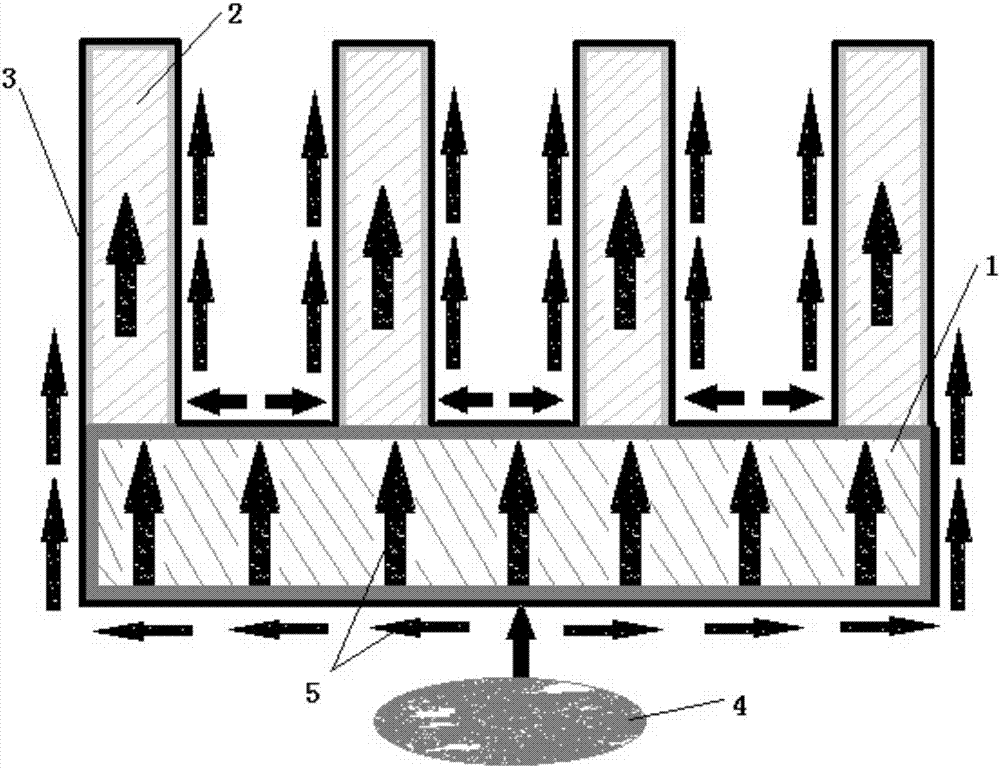

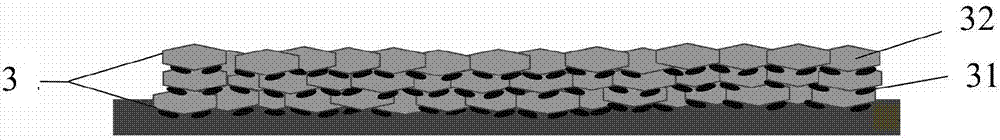

Method used

Image

Examples

Embodiment 1

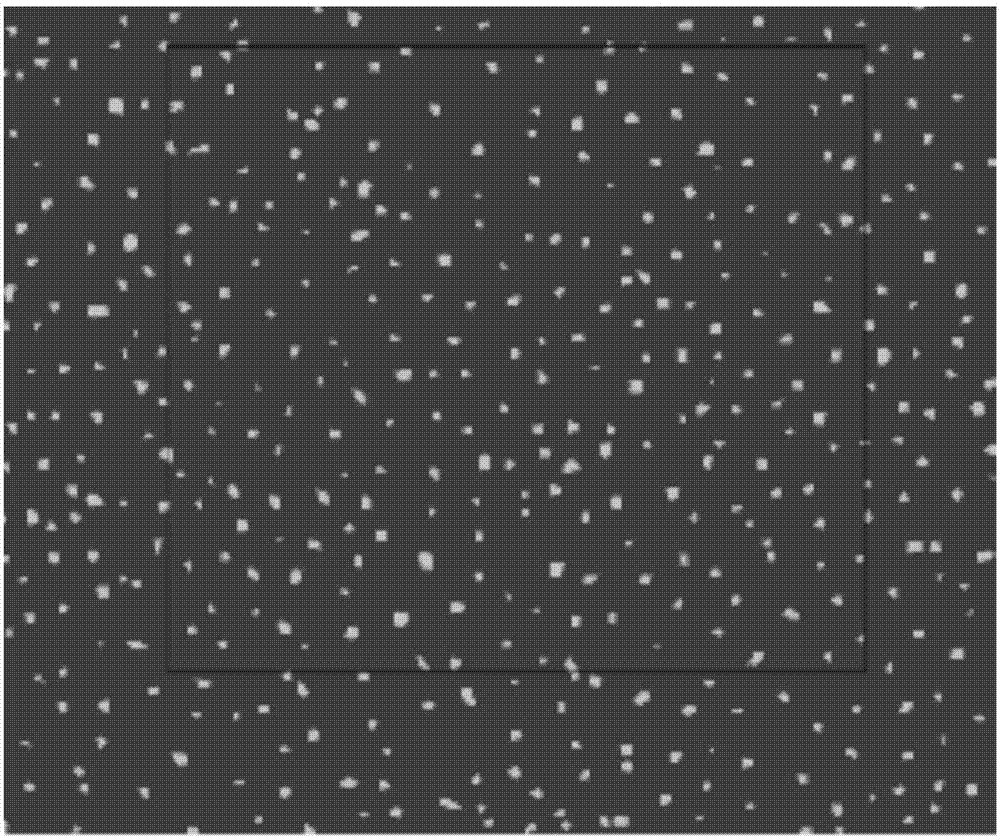

[0053] Firstly, a graphene oxide quantum dot solution is prepared. Using T700 12K (12,000 filaments) polyacrylonitrile-based carbon fiber tow as raw material, the carbon fiber has a monofilament diameter of 7 μm, which is composed of microcrystalline graphite sheet structure, and the three-dimensional size of the microcrystalline graphite is 10-40nm. The lamellar orientation is 90% compared to the fiber axis orientation. Cut the tip surfaces of the above 78 bundles of carbon fiber tows, and place vertically above the electrolytic cell filled with a 0.5M sodium hydroxide aqueous solution, and connect it as an anode to the positive pole of a DC power supply; 2 The SS 304 stainless steel mesh is completely immersed in the solution, and is used as the cathode to connect with the negative pole of the DC power supply; carefully adjust the parallel distance between the neat tip surface of the carbon fiber tow and the liquid surface of the solution before powering on, so that it just ...

Embodiment 2

[0058] The main difference from Example 1 is that only the outer surface within 1 cm of the root of the fin in contact with the heat dissipation substrate is coated with graphene oxide quantum dots and liquid phase exfoliated graphene by a spray coating process. The dispersion liquid of composite nanomaterials was dried at 120°C to form a graphene heat conduction layer with an average thickness of 0.5±0.1μm and an in-plane thermal conductivity of 1688W / m·K, and a heat sink modified with graphene heat conduction coating was obtained.

[0059] Similarly, a 150W LED lamp was installed as a heat source on the above-mentioned heat sink before and after modification of the graphene thermally conductive coating, and the natural heat dissipation effect was compared by detecting the surface temperature of the LED lamp under stable operation. The results showed that the LED before modification The surface temperature of the lamp is 85°C, and it is 78°C after modification.

Embodiment 3

[0061] The main difference from Example 1 is: after the heat dissipation base material and the fins are independently processed and formed, the dispersion liquid of the composite nanomaterial composed of graphene oxide quantum dots and liquid-phase exfoliated graphene is coated respectively by spraying process, After drying at 120°C, a graphene heat-conducting layer with an average thickness of 0.5±0.1μm and an in-plane thermal conductivity of 1688W / m·K is formed, and then the heat-dissipating base material and fins are connected into one body by a slotting process to obtain a graphene heat-conducting layer Coating modified radiator.

[0062] Similarly, a 150W LED lamp was installed as a heat source on the above-mentioned heat sink before and after modification of the graphene thermally conductive coating, and the natural heat dissipation effect was compared by detecting the surface temperature of the LED lamp under stable operation. The results showed that the LED before modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com