Metal complex flame retardant and preparation method thereof

A technology of metal complexes and flame retardants, which is applied in the field of metal complexes and flame retardants and its preparation, can solve problems such as rare research on complexes, achieve high yield, high thermal stability, and simple post-processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

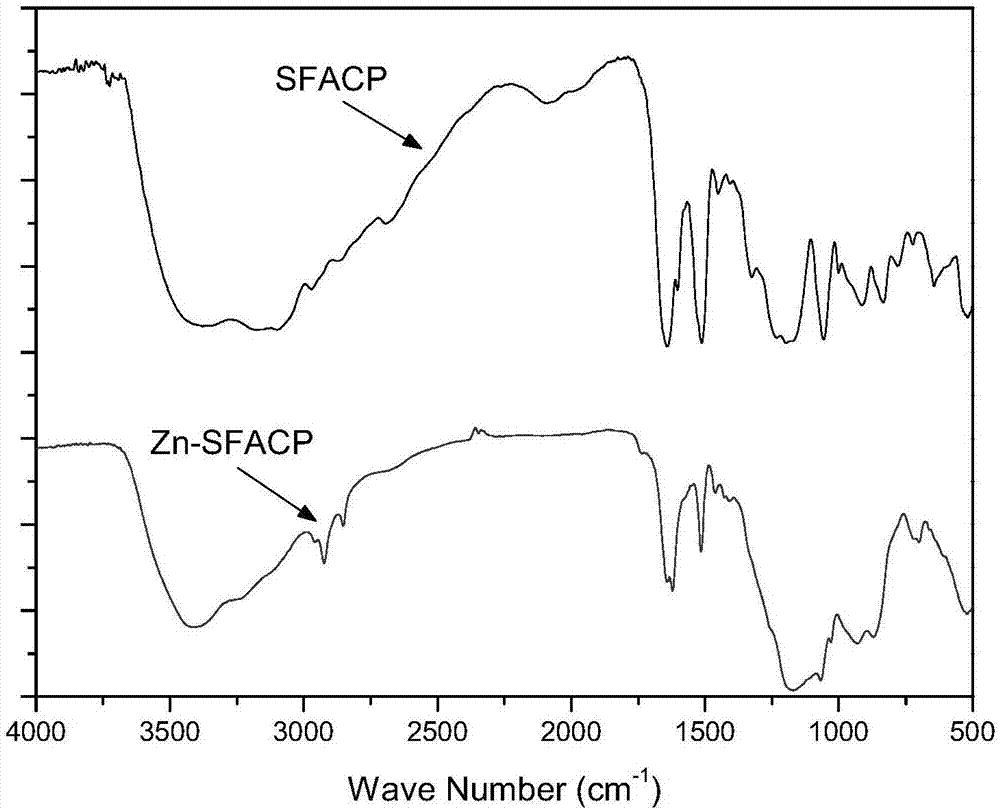

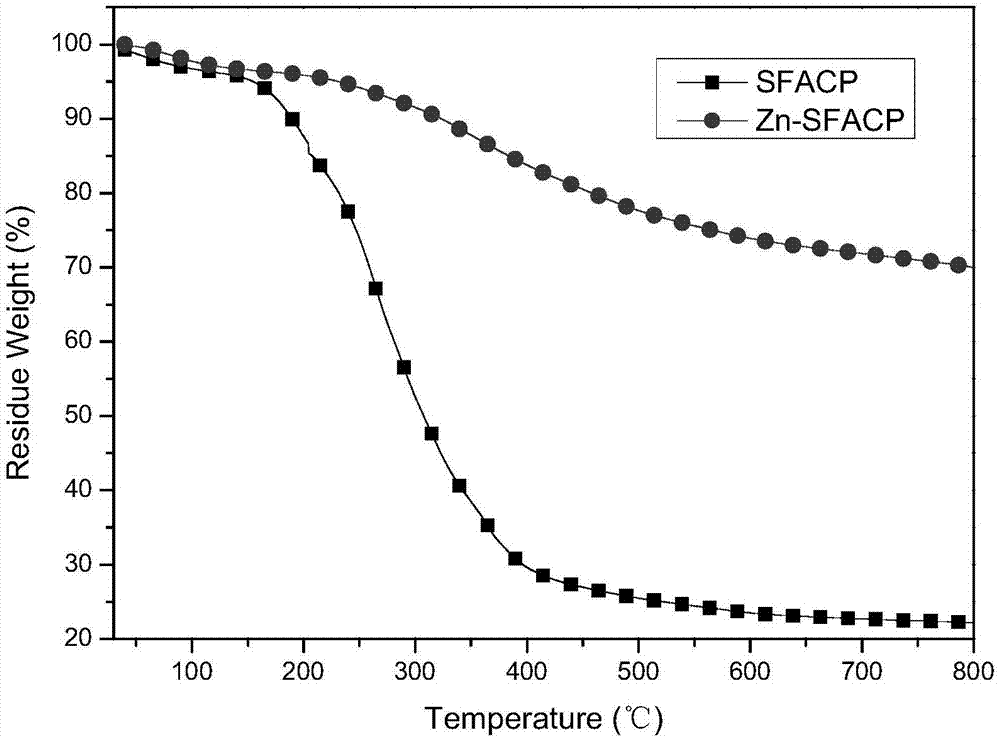

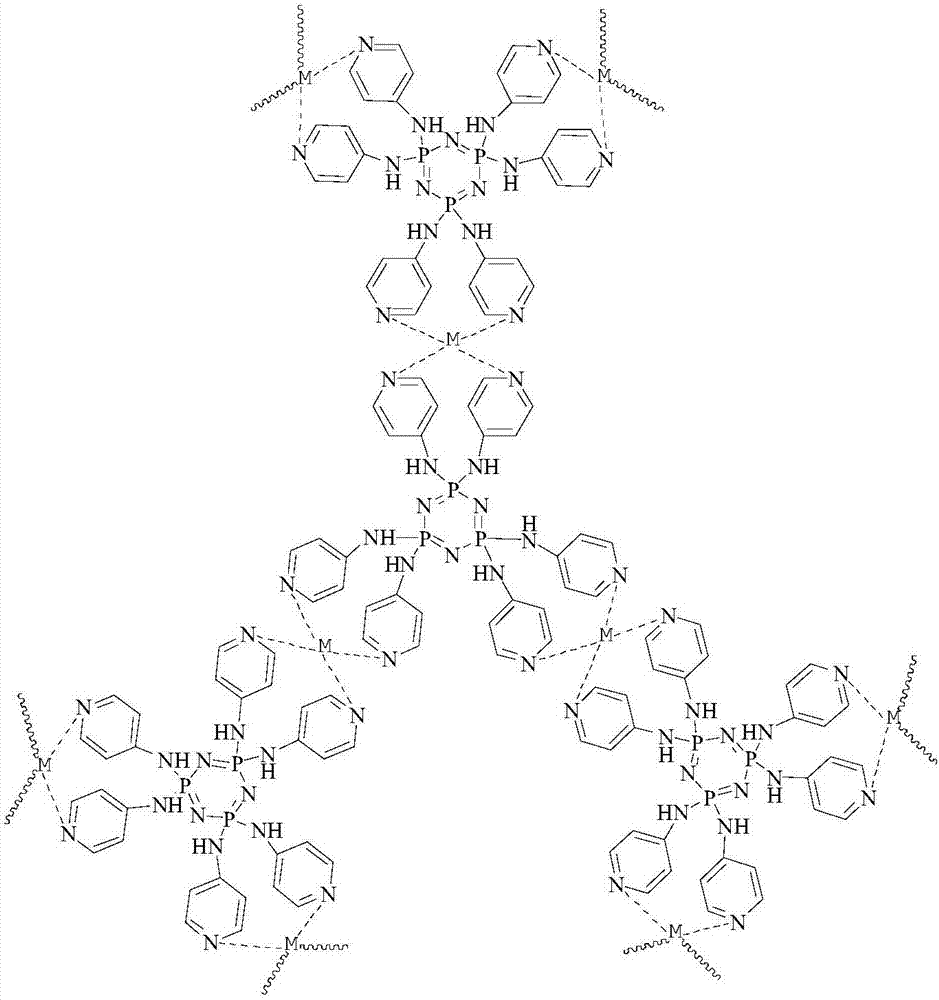

[0025] Fully dissolve 0.1mol HCCP in 60ml tetrahydrofuran, add 0.4mol sodium carbonate and stir evenly, fill with N 2 30min; then dropwise add 50ml of tetrahydrofuran solution containing 0.72mol 4-aminopyridine therein, heat up to reflux, react for 10h, cool the solution to room temperature, filter, wash three times with tetrahydrofuran, and vacuum-dry at 80°C for 24h to obtain the ligand six ( 4-aminopyridine) cyclotriphosphazene (SFACP), yield 95%. in N 2 Under protection, add 0.1mol SFACP, 0.55mol zinc acetate, and 300ml ethanol into a 500ml three-neck flask, stir thoroughly, and after completely dissolving, heat up to reflux. After reacting for 18 hours, slowly cool the solution to room temperature, filter, and wash with ethanol Wash twice, wash once with distilled water, and vacuum dry at 80° C. for 24 hours to obtain the target product metal complex flame retardant Zn-SFACP with a yield of 87%. (The infrared spectrograms of SFACP and Zn-SFACP are shown in figure 1 , t...

Embodiment 2

[0027] Fully dissolve 0.1mol HCCP in 60ml tetrahydrofuran, add 0.9mol sodium hydroxide and stir evenly, fill with N 2 30min; then dropwise add 60ml of tetrahydrofuran solution containing 0.74mol 4-aminopyridine, heat up to reflux, react for 17h, cool the solution to room temperature, filter, wash three times with tetrahydrofuran, and vacuum dry at 80°C for 24h to obtain the ligand six ( 4-aminopyridine) cyclotriphosphazene (SFACP), yield 97%. in N 2 Under protection, add 0.1mol SFACP, 0.45mol palladium acetate, and 300ml ethanol into a 500ml three-neck flask, stir thoroughly, and after completely dissolving, heat up to reflux. After 24 hours of reaction, slowly cool the solution to room temperature, filter, and wash with ethanol Wash twice, wash once with distilled water, and vacuum dry at 80° C. for 24 hours to obtain the target product metal complex flame retardant Pd-SFACP with a yield of 80%.

Embodiment 3

[0029] in N 2 Under protection, add 0.2mol HCCP, 1.3mol 4-aminopyridine, 0.7mol triethylamine, and 160ml tetrahydrofuran into the reaction vessel, raise the temperature to reflux for 12 hours, cool and filter, wash the filter cake twice with tetrahydrofuran and once with dichloromethane , 80 ° C vacuum drying for 24 hours to obtain the ligand six (4-aminopyridine) cyclotriphosphazene (SFACP), the yield of 96%. in N 2 Under protection, add 0.1mol SFACP, 0.2mol cobalt acetate, 0.2mol nickel acetate, and 300ml ethanol into a 500ml three-neck flask, fully stir and dissolve, heat up to reflux and continue the reaction for 24h, slowly cool the solution to room temperature, filter, and wash with ethanol Wash twice, wash once with distilled water, and vacuum dry at 80° C. for 24 hours to obtain the target product metal complex flame retardant with a yield of 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com