A kind of long-chain metal coordination expansion flame retardant and preparation method thereof

An intumescent flame retardant and metal coordination technology, which is applied in the field of long-chain metal coordination intumescent flame retardant and its preparation, can solve the damage of material mechanical properties and processing properties, and the processing and recycling of flame retardant polymers difficult, low flame retardant efficiency and other problems, to achieve the effect of high yield, simple product post-processing, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

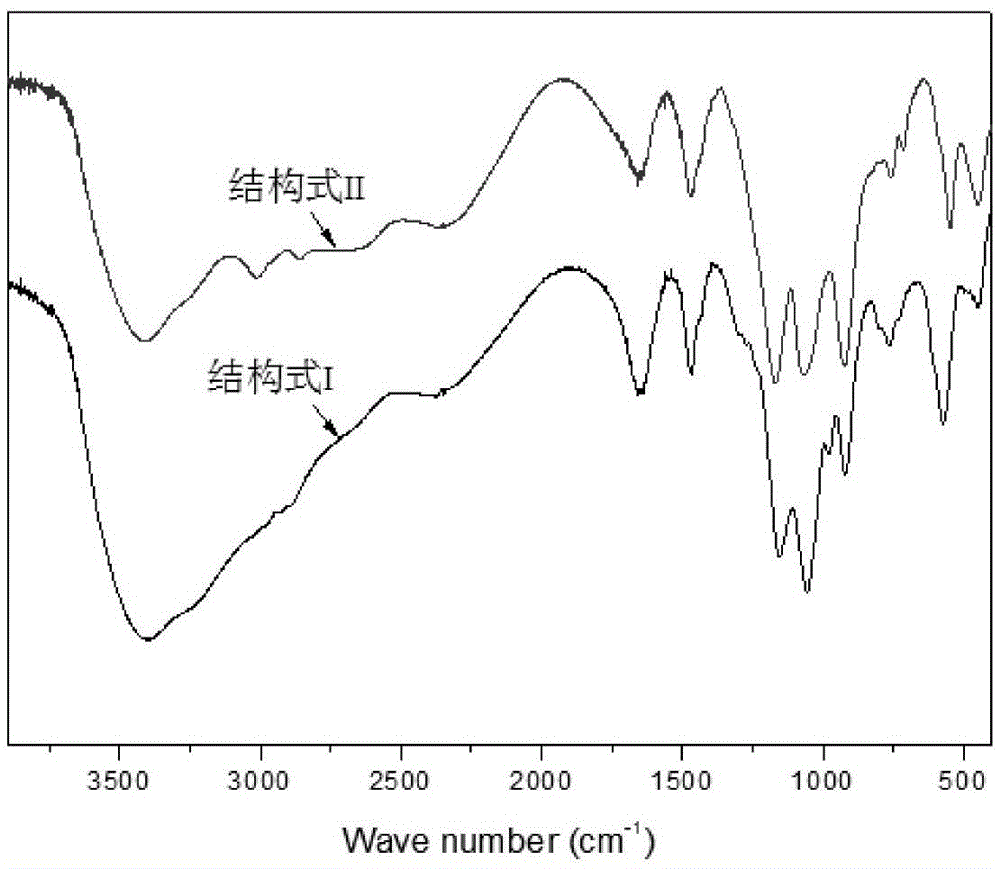

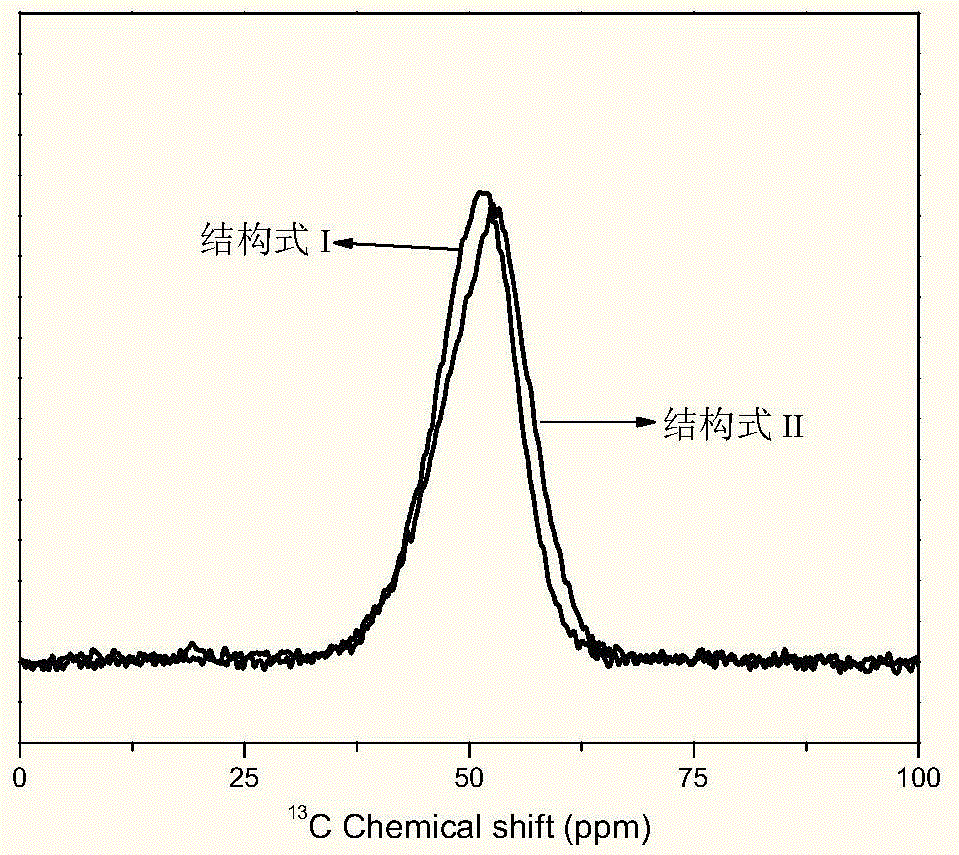

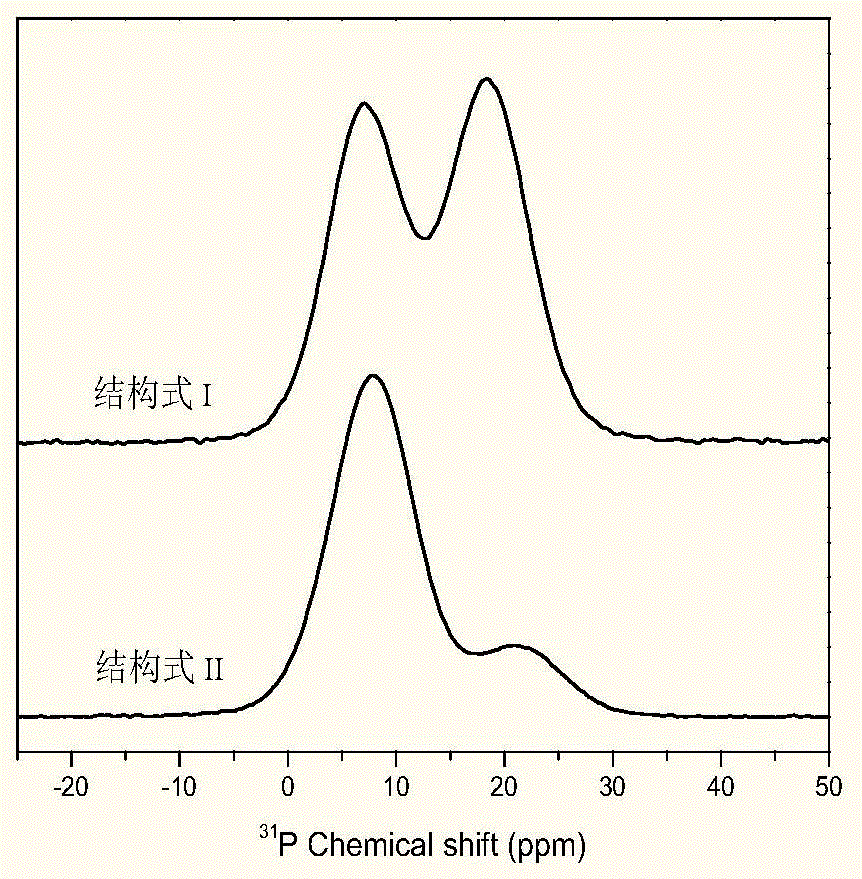

[0025] In a 250ml four-necked flask equipped with a magnetic stirrer, a thermometer, and a spherical condenser, add 0.2mol of phosphorous acid, 100ml of concentrated hydrochloric acid, and polyethyleneimine (1mmol) with a degree of polymerization of 100, heat to reflux under stirring, and take 37% of Add 32ml of formaldehyde solution to the flask dropwise within 1 hour. The reaction was then continued for 2 h at reflux temperature. After the reaction, cool to room temperature and neutralize to neutral with ethylene glycol amine, wash with absolute ethanol three times, and filter to obtain the product with structural formula (II), with a yield of 95%). The compound with structural formula (II), namely PEIP (0.53mmol), zinc acetate (0.1mol), sodium hydroxide 0.05mol, and absolute ethanol 500ml, was stirred and heated to reflux for 7 hours, filtered and washed three times with absolute ethanol, filtered Obtaining structural formula is the product (the infrared spectrum of struct...

Embodiment 2

[0028] In a 250ml four-neck flask equipped with a magnetic stirrer, a thermometer and a spherical condenser, add 0.2mol of phosphorous acid, 100ml of concentrated hydrochloric acid, and a degree of polymerization of 100 polyethyleneimine (1mmol), heat and reflux under stirring, and take 37% formaldehyde aqueous solution 32ml, dropwise into the flask within 1h. The reaction was then continued for 2 h at reflux temperature. After the reaction, cool to room temperature, neutralize to neutral with ethylene glycol amine, wash with absolute ethanol three times, and filter to obtain the product with structural formula (II), with a yield of 95%. The compound with structural formula (II), namely PEIP (0.53mmol), manganese acetate (0.1mol), sodium hydroxide 0.05mol, and absolute ethanol 500ml, was stirred and heated to reflux for 7 hours, filtered and washed three times with absolute ethanol, filtered Obtaining structural formula is the product of (I) (the infrared spectrogram of struc...

Embodiment 3

[0031] In a 250ml four-neck flask equipped with a magnetic stirrer, a thermometer and a spherical condenser, add 0.2mol of phosphorous acid, 100ml of concentrated hydrochloric acid, and a degree of polymerization of 100 polyethyleneimine (1mmol), heat and reflux under stirring, and take 37% formaldehyde aqueous solution 32ml, dropwise into the flask within 1h. The reaction was then continued for 2 h at reflux temperature. After the reaction, cool to room temperature, neutralize to neutral with ethylene glycol amine, wash with absolute ethanol three times, and filter to obtain the product with structural formula (II), with a yield of 95%. The compound with structural formula (II), namely PEIP (0.53mmol), cobalt acetate (0.1mol), sodium hydroxide 0.05mol, and absolute ethanol 500ml, was stirred and heated to reflux for 7 hours, filtered and washed three times with absolute ethanol, filtered Obtaining structural formula is the product of (I) (the infrared spectrogram of structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com