Shrinkage-compensating foam concrete for lightweight composite partition board

A foamed concrete and composite partition wall technology, applied in the field of wall materials, can solve the problems of reduced strength, peeling off of panels, different combustion conditions, etc., and achieve the effects of reducing production cost, labor intensity, and shrinkage difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

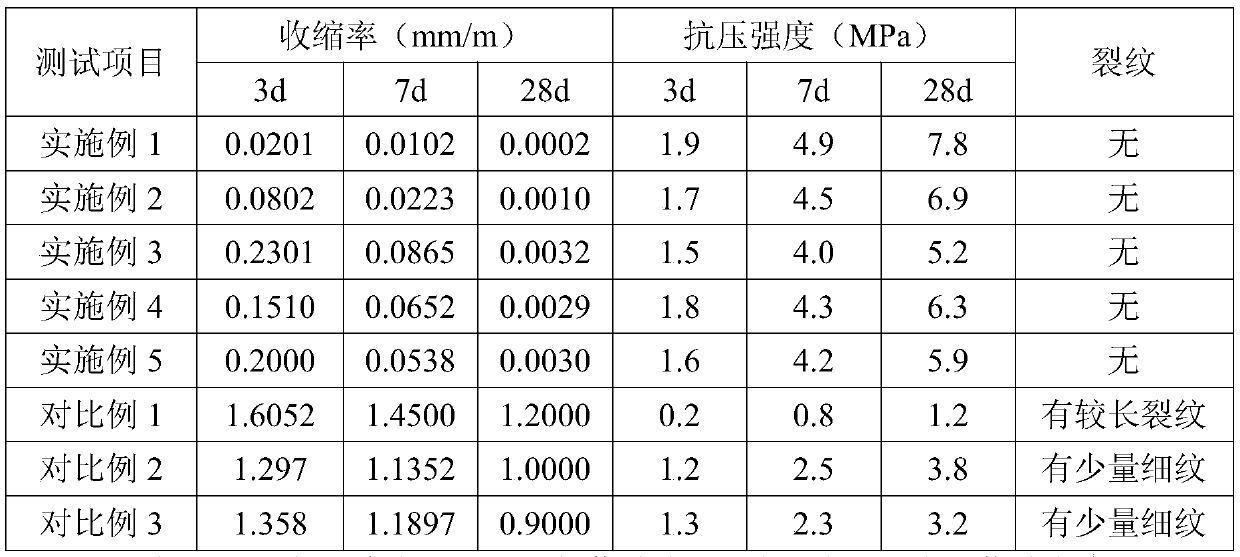

Examples

Embodiment 1

[0023] A shrinkage-compensating foam concrete for lightweight composite partition boards: add 225g of cement, 75g of fluidized bed fly ash, 2g of polyester fiber, 2.4g of sodium silicate, 1.1g of calcium sulfate, 2g of water reducing agent, 2g of hydroxypropyl methyl cellulose ether and 95g of water, stir well to form a cement slurry, then dilute 12g of foaming agent at a ratio of 1:20, the foaming agent is prepared by a foaming machine, and then the prepared foam is added to In the well-stirred cement slurry, foaming is carried out to obtain a foamed concrete slurry. The fluidized bed fly ash is desulfurized ash after desulfurization by spraying calcium in the furnace, and its fineness is 0.045mm and the sieve residue is 5%. The polyester fiber has a length of 40 mm and a breaking strength of 5 cN / dtex. The water reducer is a polycarboxylate high-performance water reducer, the water reducer has a solid content of 30 wt%, and a water reducing rate of 27%.

Embodiment 2

[0025] Add 250g of cement, 80g of fluidized bed fly ash, 2.2g of polyester fiber, 3.2g of sodium silicate, 0.8g of calcium sulfate, 105g of water, 2.3g of water reducing agent, and 1.8g of Brunei gum into the mixer, and stir evenly to form Cement slurry, then dilute 15g of foaming agent according to 1:20, the foaming agent is prepared by foaming machine to produce foam, and then the prepared foam is added to the well-stirred cement slurry for mixing and foaming to obtain foamed concrete slurry body. The fluidized bed fly ash is desulfurized ash after desulfurization by spraying calcium in the furnace, and its fineness is 0.045mm and the sieve residue is 9%. The polyester fiber has a length of 50 mm and a breaking strength of 2 cN / dtex. The water reducer is a high-performance polycarboxylate water reducer, the water reducer has a solid content of 25 wt%, and a water reducing rate of 27%.

Embodiment 3

[0027] Add 160g of cement, 50g of fluidized bed fly ash, 1.5g of polyester fiber, 3g of sodium silicate, 1g of calcium sulfate, 85g of water, 1.5g of water reducing agent, and 1g of methyl cellulose ether into the mixer, and stir evenly to form cement slurry, and then dilute 10g of foaming agent according to 1:20, the foaming agent is prepared by a foaming machine to produce foam, and then the prepared foam is added to the stirred cement slurry, and the foam is mixed to obtain a foam concrete slurry . The fluidized bed fly ash is desulfurized ash after desulfurization by spraying calcium in the furnace, and its fineness is 0.045 mm and the sieve residue is 12%. The polyester fiber has a length of 30 mm and a breaking strength of 3 cN / dtex. The water reducer is a high-performance polycarboxylate water reducer, the water reducer has a solid content of 28 wt%, and a water reducing rate of 27%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com