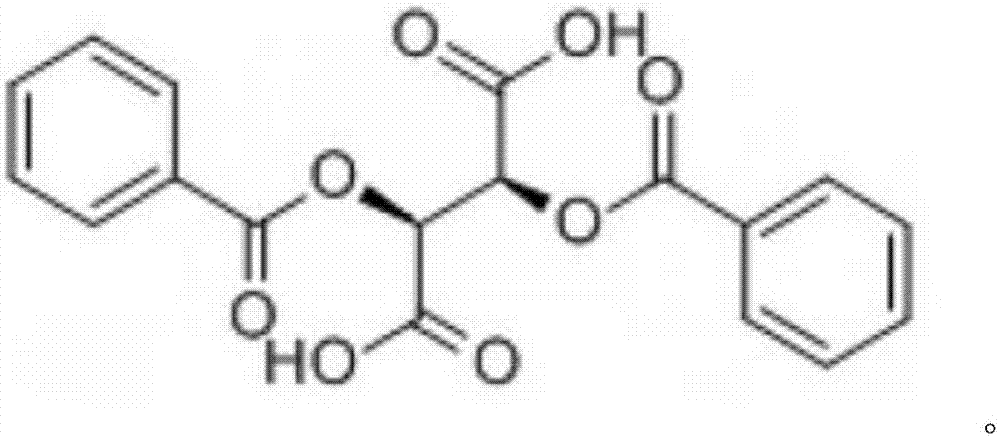

Novel synthesis method of D-dibenzoyl tartaric acid

A technology of dibenzoyl tartaric acid and a new method is applied in the directions of organic chemistry methods, chemical instruments and methods, carboxylate preparation, etc., and can solve the problems of strong irritation of raw materials, low utilization rate of raw materials, limitations in production and processing, etc. Easy operation, improved yield and product quality, mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In the embodiment of the present invention, a new synthetic method of D-dibenzoyl tartaric acid comprises the following steps:

[0021] 1) Weigh tartaric acid and silicone oil, put them into a reaction kettle and stir for 40min at a temperature of 52°C. The mass volume ratio of tartaric acid and silicone oil is 1kg:8L; then, under stirring conditions of 100r / min, add ferric chloride, The addition of ferric chloride is 1% of tartaric acid quality. Then raise the temperature to 63°C, then continuously add benzamide to the reaction kettle in 3 minutes, and then continue to stir at this temperature for 2.3 hours to obtain mixed material A; the mass ratio of tartaric acid to benzamide is 1 :2.

[0022] 2) Add water equal to the volume of silicone oil to the mixture material A, stir at a stirring speed of 600r / min and a temperature of 80°C for 15 minutes, and after standing for 30 minutes, use a low-temperature high-speed centrifuge for centrifugation at a speed of 14000r / mi...

Embodiment 2

[0025] In the embodiment of the present invention, a new synthetic method of D-dibenzoyl tartaric acid comprises the following steps:

[0026] 1) Weigh tartaric acid and silicone oil, put them into a reaction kettle and stir for 50 minutes at a temperature of 55°C. The mass volume ratio of tartaric acid and silicone oil is 3kg:10L; then, under stirring conditions of 120r / min, add ferric chloride, The addition of ferric chloride is 3% of tartaric acid quality. Then raise the temperature to 68°C, then continuously add benzamide into the reaction kettle in 4min, and then continue to stir at this temperature for 2.5h to prepare mixed material A; the mass ratio of tartaric acid to benzamide is 1 :4.

[0027] 2) Add water equal to the volume of silicone oil to the mixture material A, stir for 20 minutes at a stirring speed of 800r / min and a temperature of 82°C, and after standing for 30 minutes, use a low-temperature high-speed centrifuge for centrifugal separation at a centrifugal...

Embodiment 3

[0030] In the embodiment of the present invention, a new synthetic method of D-dibenzoyl tartaric acid comprises the following steps:

[0031] 1) Weigh tartaric acid and silicone oil, put them into a reaction kettle and stir for 45min at a temperature of 54°C. The mass volume ratio of tartaric acid and silicone oil is 2kg:9L; then, under stirring conditions of 110r / min, add ferric chloride, The addition of ferric chloride is 2% of tartaric acid quality. Then raise the temperature to 65°C, then continuously add benzamide to the reaction kettle in 4 minutes, and then continue to stir at this temperature for 2.4 hours to obtain mixed material A; the mass ratio of tartaric acid to benzamide is 1 :3.

[0032] 2) Add water equal to the volume of silicone oil to the mixture material A, stir at a stirring speed of 700r / min and a temperature of 81°C for 18min, and after standing for 30min, use a low-temperature high-speed centrifuge to centrifuge and separate at a centrifugal speed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com