A siloxane prepolymer solution and a preparing method thereof

A siloxane and prepolymerization technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of high chemical activity, loss of surface function, poor binding force, etc., and achieve simple process, hydrophilization, and mild conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a kind of preparation method of siloxane prepolymerization liquid, it comprises the following steps:

[0022] S1, adding polyalkoxysilane, functional monomer and initiator into an inert organic solvent to obtain a mixture;

[0023] S2, heating the mixture and performing a polymerization reaction under an inert atmosphere to obtain the siloxane prepolymer liquid.

[0024] In step S1, the functional monomer can be selected according to the functional requirements of the surface modification, specifically a monomer containing an unsaturated carbon-carbon double bond (C=C). The polyalkoxysilane is polyalkoxysilane containing unsaturated carbon-carbon double bond (C=C). The polyalkoxysilane and the functional monomer undergo a polymerization reaction under the action of the initiator to obtain a prepolymer. Specifically, the polyalkoxysilane is vinyltrimethoxysilane, vinyltriethoxysilane, methylvinyldiethoxysilane, methacryloxypropyltrimethylsilane ...

Embodiment 1

[0036](1) Add 1g of hydroxyethyl methacrylate, 1g of vinyltrimethoxysilane and 0.05g of benzoyl peroxide to 100mL of absolute ethanol in turn, pass through industrial nitrogen, and 200r at room temperature / min Mechanical stirring for 20min;

[0037] (2) Turn on the heating and gradually increase the temperature to 65° C., in an atmosphere of industrial nitrogen, mechanically stir at a speed of 200 r / min and react for 36 hours. After the reaction is finished, the heating is turned off, and the prepolymerization solution of the hydroxyethyl methacrylate / vinyltrimethoxysilane copolymer is obtained after the temperature is sufficiently lowered.

[0038] The polyurethane sponge is soaked in the diluted solution of the obtained pre-polymerization solution, and the surface cross-linking treatment can improve the hydrophilicity of the surface of the polyurethane sponge.

Embodiment 2

[0040] (1) Add 4g of N-vinylpyrrolidone, 3g of vinyltriethoxysilane and 0.1g of azobisisoheptyl cyanide to 100mL of triethyl phosphate successively, feed high-purity nitrogen, and 250r / min mechanical stirring at room temperature for 30min;

[0041] (2) Turn on the heating and gradually increase the temperature to 80° C., in an atmosphere of high-purity nitrogen, mechanically stir at a speed of 250 r / min and react for 24 hours. Turn off the heating after the reaction is finished, and obtain a prepolymer liquid of N-vinylpyrrolidone / vinyltriethoxysilane copolymer after the temperature is sufficiently lowered.

[0042] The polypropylene non-woven fabric is immersed in the diluted solution of the obtained pre-polymerization solution, and after surface cross-linking treatment, the polypropylene non-woven fabric with super-hydrophilic properties can be obtained.

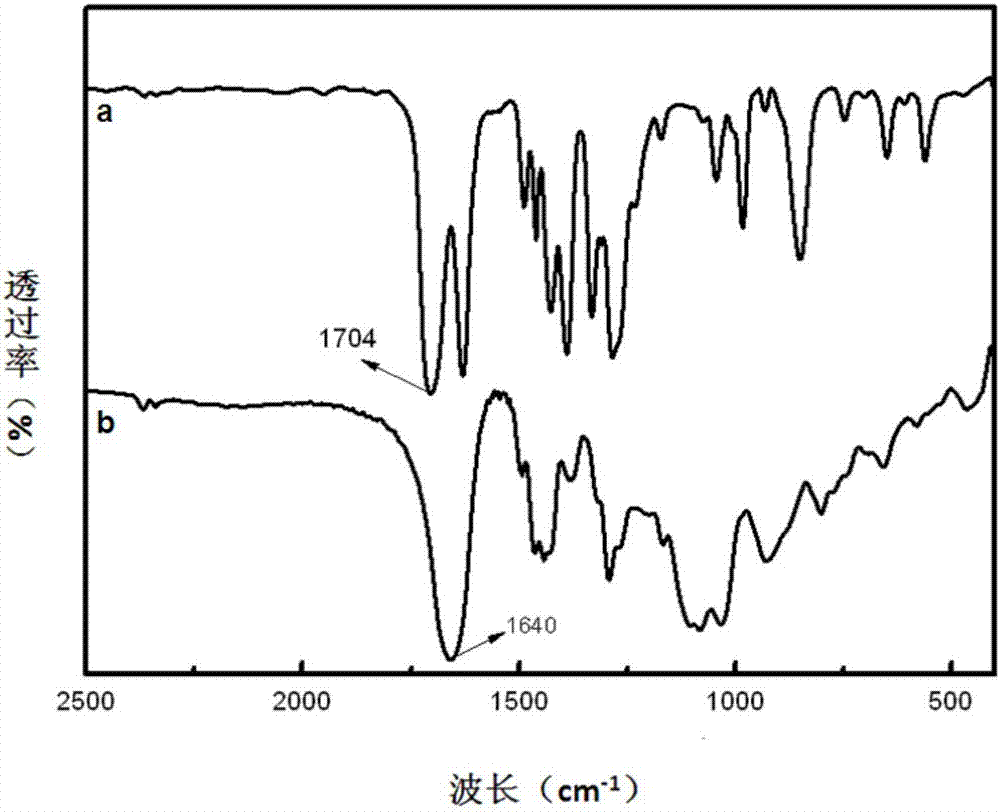

[0043] Depend on figure 1 It can be seen that the prepolymer (see curve b) is at 1704cm -1 (corresponding to the C=C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com