A kind of antibacterial breathable membrane masterbatch and preparation method thereof

A gas-permeable film and masterbatch technology, applied in the field of polyethylene materials, can solve the problems of low controllability of micropore size, high product defective rate, and many influencing parameters, and achieve long-lasting inhibition of bacterial growth, strong and long-lasting antibacterial effect, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

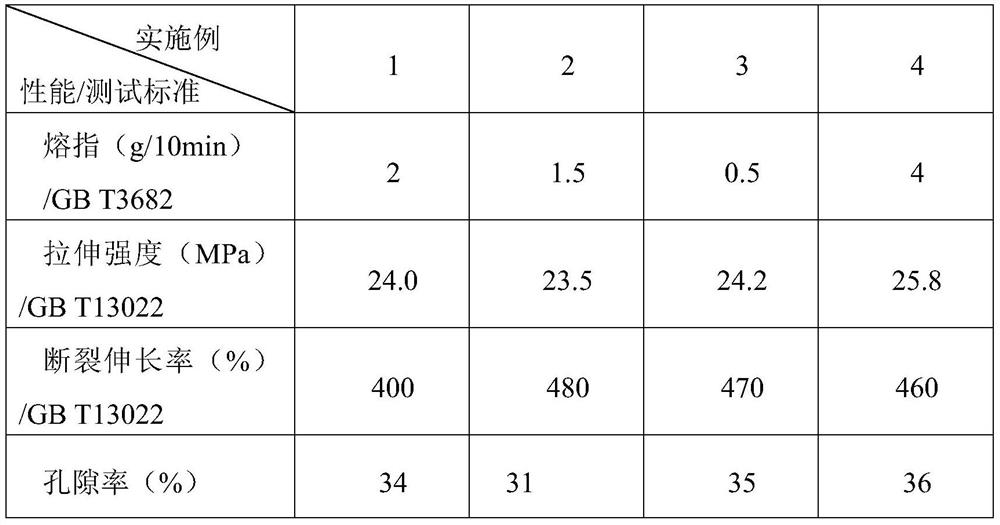

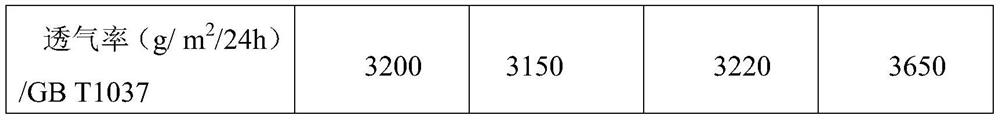

[0032] 280g PE-7042, 300g PE-8320, 400g calcium carbonate LD-1000C, 60g water-soluble organic matter ethylene glycol, 1g EBS / P-130, 3g B6000 antibacterial agent, 1g antioxidant 1010 and 2g antioxidant 1076 into the airtight After mixing in the mixer for 5 minutes, the banburying temperature is 150-180°C, melt blending, extrusion and traction in a twin-screw extruder. The length-to-diameter ratio of the extruder is 32, and the barrel temperature of the extruder is 180°C. , fixed main screw speed 180 rpm. Use a casting machine to form a film and wind it up. The barrel temperature of the tape casting machine is 250-260°C, and the die head temperature is 260°C-280°C. See Table 1 for test data.

Embodiment 2

[0034] 400g PE-8008, 500g PE-8320, 50g calcium carbonate LD-1000C, 100g water-soluble organic matter ethylene glycol, 1gEBS / P-130, 0.5g calcium stearate, 0.5g zinc stearate, 1g lead stearate , 1g barium stearate, 1g pentaerythritol stearate, 5g B6000 antibacterial agent, 1g antioxidant 1010 were put into the internal mixer and mixed for 5 minutes. Melt blending extrusion and traction were carried out, the aspect ratio of the extruder was 40, the temperature of the barrel of the extruder was 180° C., and the rotational speed of the main screw was fixed at 200 rpm. Use a casting machine to form a film and wind it up. The barrel temperature of the tape casting machine is 250-260°C, and the die head temperature is 260°C-280°C. See Table 1 for test data.

Embodiment 3

[0036] Put 940g PE-7042, 50g calcium carbonate LD-1000C, 100g water-soluble organic matter ethylene glycol, 1g calcium stearate, 7gB6000 antibacterial agent and 2g antioxidant 168 into the internal mixer and mix for 5 minutes. 150-180°C, melt blending extrusion and traction in a twin-screw extruder, the aspect ratio of the extruder is 37, the barrel temperature of the extruder is 185°C, and the main screw speed is fixed at 190 rpm. Use a casting machine to form a film and wind it up. The barrel temperature of the tape casting machine is 250-260°C, and the die head temperature is 260°C-280°C. See Table 1 for test data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com