Composition for non-conductive adhesive film and non-conductive adhesive film containing same

A non-conductive, composite technology, applied in the direction of non-polymer adhesive additives, adhesive types, film/sheet adhesives, etc., can solve the problem of reduced stability of adhesive films and bump damage , slow curing speed and other issues, to achieve the effect of improving film adhesion, preventing wafer delamination, and increasing curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

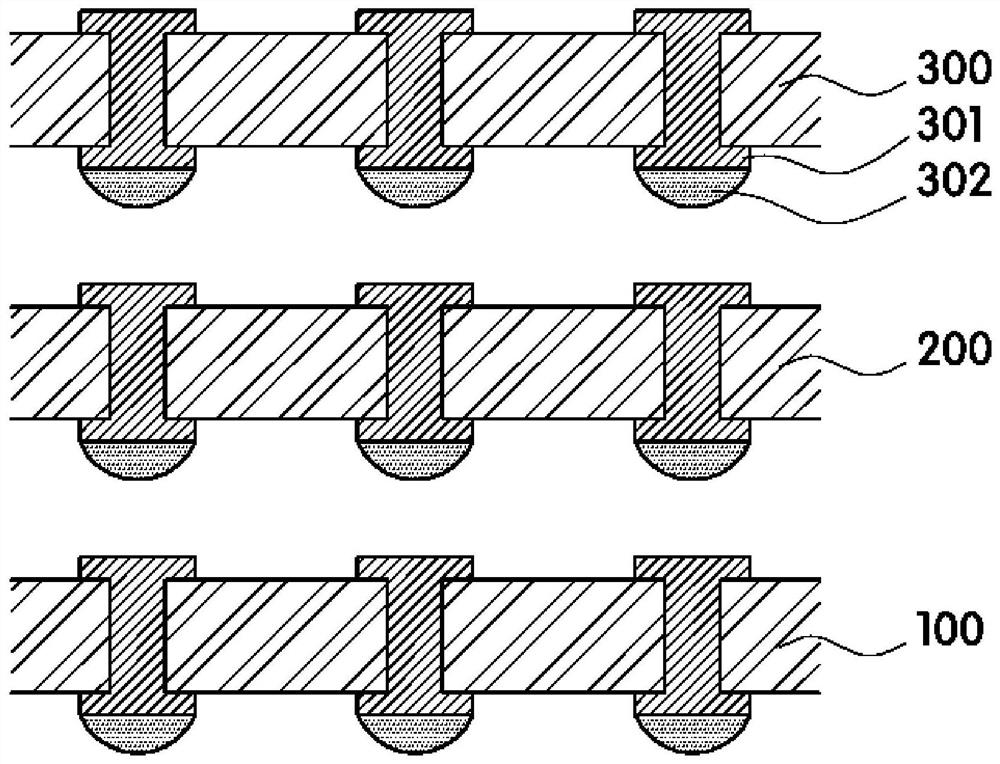

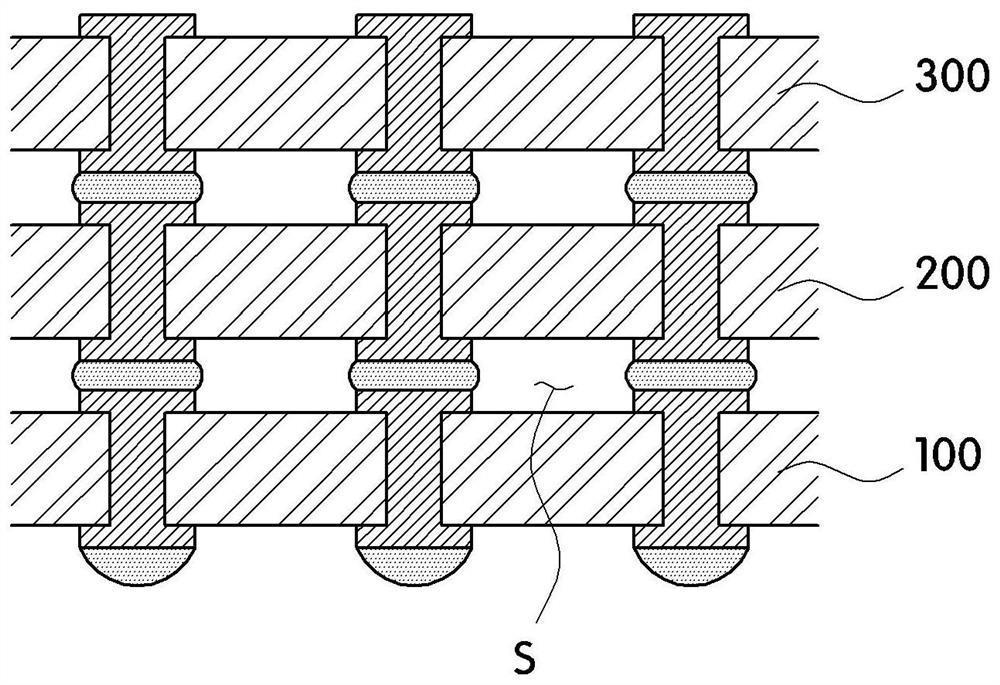

[0105] As above image 3 The production method of the adhesive film of is prepared in the following order, that is, by coating the composition for non-conductive adhesive film on the upper part of the peeling substrate, drying it, and laminating the sheet substrate, but it can also be obtained by The composition for non-conductive adhesive film is coated on the upper part of the sheet substrate which is not the peeling substrate, dried, and the peeling substrate is laminated. In the case of not laminating the peeling substrate, it is possible to prepare such figure 2 adhesive film.

[0106] At this time, the melting range of the adhesive layer in which the adhesive film composition is dried in the adhesive film according to the following Mathematical Formula 1 may be 90°C or lower, more preferably 50 to 90°C.

[0107] Mathematical formula 1

[0108] Melting interval (ΔT) = TA (°C) - TB (°C)

[0109] The above-mentioned TA is the temperature (°C) when the melt viscosity is ...

Embodiment 1

[0120] First, 100 parts by weight of the epoxy component (solid, cycloaliphatic, EHPE3150, Daicel (DAICEL)) of the first thermosetting part was dropped into the second thermosetting part of the thermosetting part. A difunctional acrylic component containing a vinyl group as a functional group (M200, Miwon Specialty Chemical Co., Ltd.). Based on the total weight of the above-mentioned epoxy components and acrylic components of 100 parts by weight, 30 parts by weight of an acrylic copolymer (KW197CHM, negamikogyo company) and 10 parts by weight of about 700,000 weight average molecular weight are dropped into the thermoplastic part. Methyl ethyl ketone as a solvent, the above-mentioned acrylic copolymer contains 2,3-epoxypropyl methacrylate (2,3-epoxypropyl methacrylate) as an epoxy group-containing acrylic monomer at 25% by weight In the copolymer, the above-mentioned methyl ethyl ketone as a solvent was mixed by using a stirrer based on 100 parts by weight of the total weight ...

Embodiment 2 to Embodiment 12

[0122] Preparation was carried out in the same manner as in Example 1, and the non-conductive adhesives in Tables 1 to 3 below were obtained by changing the composition ratio of the composition for a non-conductive adhesive film as shown in Tables 1 to 3 below. conjunctiva.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com