Skid-mounted type integration device and method for preparing hydrogen from natural gas and integrating heat-electricity-cold triple co-generation with proton exchange membrane fuel cell

A proton exchange membrane and fuel cell technology, which is used in fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the need for combined heat, power and cooling in less buildings, and is not suitable for building energy load fluctuations, heat and electricity cooling. Issues such as load matching and mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

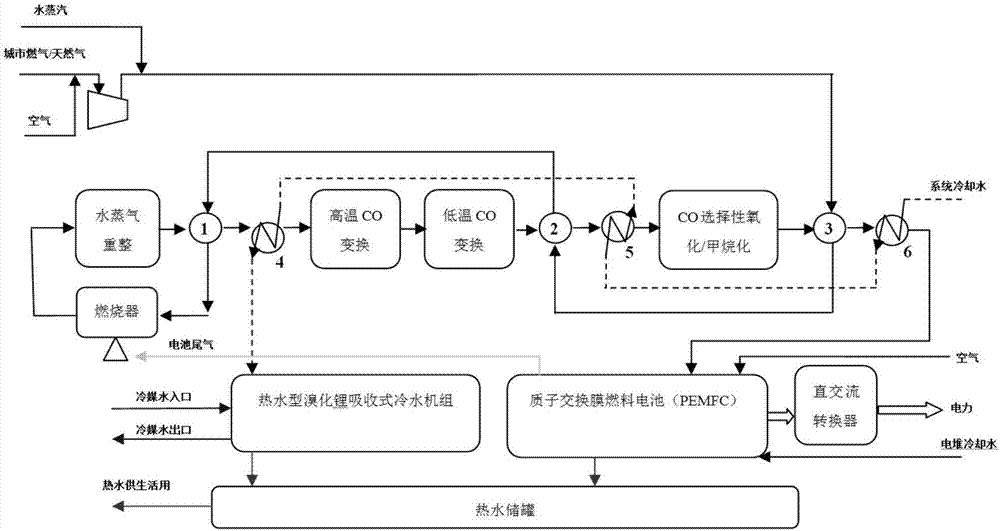

[0084] This embodiment is a schematic diagram of the process flow of a skid-mounted integrated method for producing hydrogen from natural gas and integrating thermoelectric cooling with proton exchange membrane fuel cells, in which 1: the first heat exchanger (E1); 2: the second heat exchange 3: the third heat exchanger (E3); 4: the fourth heat exchanger (E4); 5: the fifth heat exchanger (E5); 6: the sixth heat exchanger (E6);

[0085] The schematic diagram of this process is shown in figure 1 , the raw material gas is city gas or natural gas after desulfurization, the main component is CH 4 , containing a small amount of C 2 + Hydrocarbons. In this case, the typical natural gas source is selected as raw material gas. The components and main process parameters are shown in Table 1:

[0086] Table 1 Composition of feed gas

[0087]

[0088] The composition and main process parameters of the air are shown in Table 2:

[0089] Table 2 Composition of Air

[0090] ...

Embodiment 2

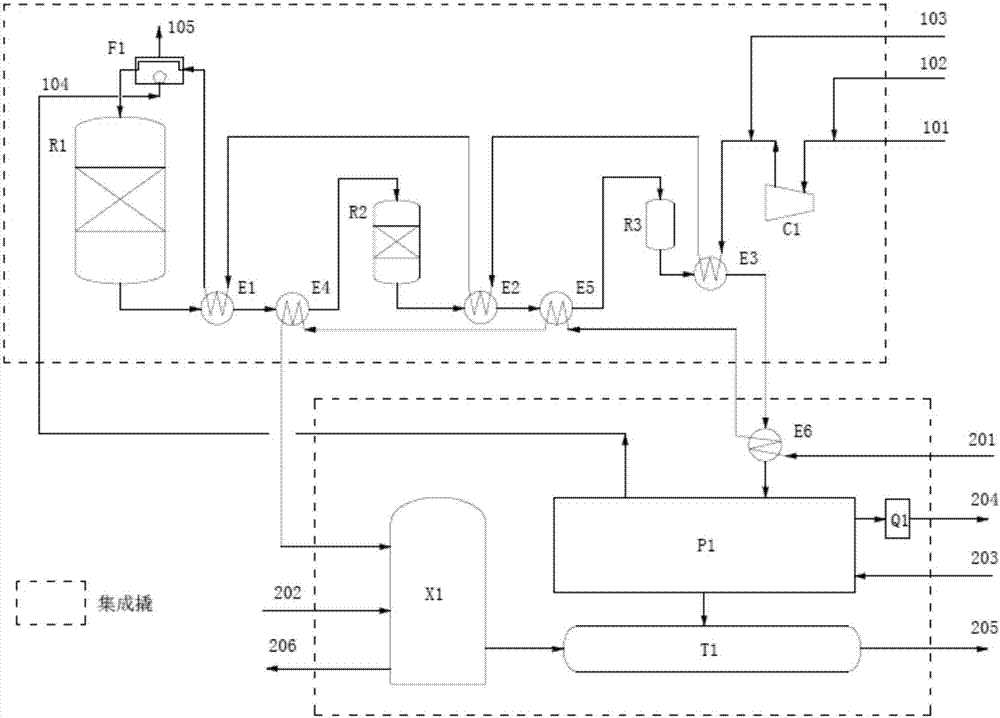

[0111] This example is a skid-mounted integrated device for producing hydrogen from natural gas and integrating heat, electricity, and cooling with a proton exchange membrane fuel cell. The schematic diagram of the result is as follows figure 2 shown, where:

[0112] C1: Feed gas compressor; R1: Methane steam reforming reactor; R2: High and low temperature CO shift reactor; R3: CO selective oxidation or CO selective methanation reactor; F1: Combustion heater; E1: The first heat exchanger; E2: the second heat exchanger; E3: the third heat exchanger; E4: the fourth heat exchanger; E5: the fifth heat exchanger; E6: the sixth heat exchanger; P1: proton exchange Membrane fuel cell stack; Q1: DC-AC converter; X1: hot water lithium bromide absorption refrigeration unit; T1: hot water storage tank; 101: feed gas (city gas or natural gas after desulfurization); 102: air; 103 : water vapor; 104: battery exhaust; 105: combustion exhaust; 201: system cooling water; 202: refrigerant wate...

Embodiment 3

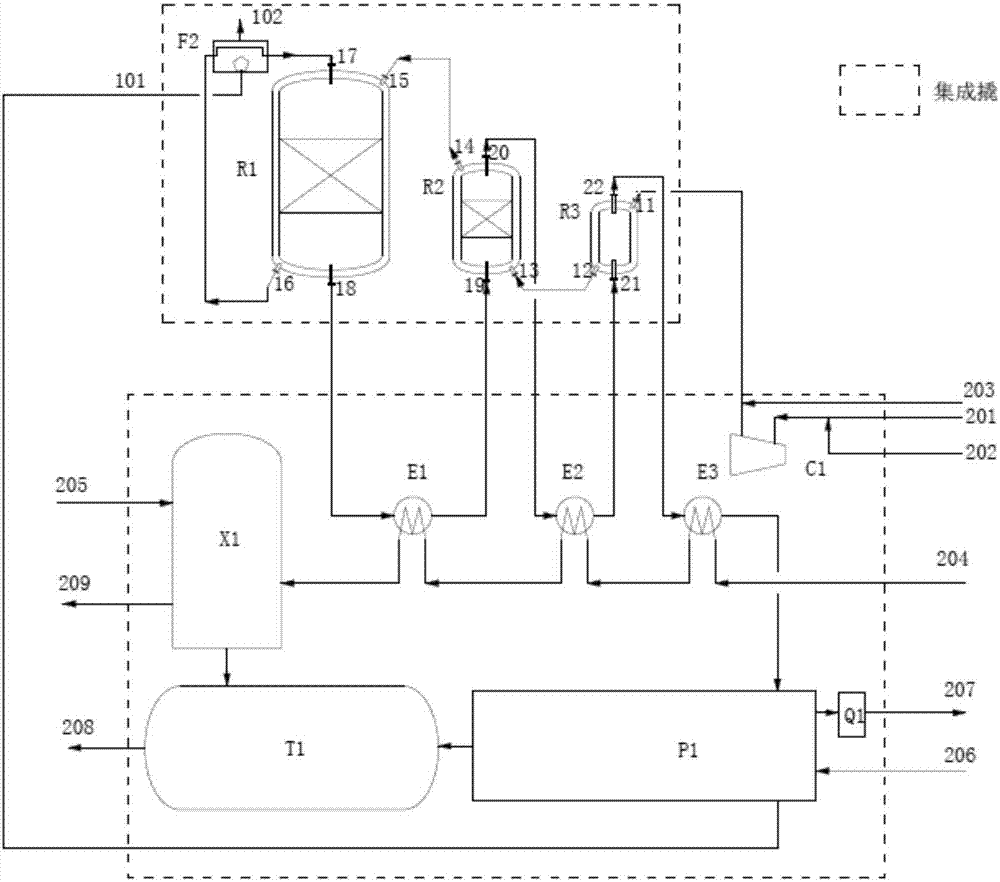

[0132] This embodiment is another skid-mounted integrated device for producing hydrogen from natural gas and integrating thermoelectricity and cooling with a proton exchange membrane fuel cell. The structural diagram is as follows image 3 shown, where:

[0133]C1: Feed gas compressor; R1: Methane steam reforming reactor with gas channel jacket layer; R2: high and low temperature CO shift reactor with gas channel jacket layer; R3: gas channel clamp Jacketed CO selective oxidation or CO selective methanation reactor; F1: fired heater; E1: first heat exchanger; E2: second heat exchanger; E3: third heat exchanger; P1: proton exchange Membrane fuel cell stack; Q1: DC-AC converter; X1: hot water lithium bromide absorption refrigeration unit; T1: hot water storage tank; 201: feed gas (city gas or natural gas after desulfurization); 202: air; 203 : water vapor; 101: battery exhaust; 102: combustion exhaust; 204: system cooling water; 205: refrigerant water input; 206: stack cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com