A ZnO photocatalytic material modified with porous carbon and a preparing method thereof

A technology of photocatalytic materials and porous carbon, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of insufficient specific surface area of ZnO photocatalysts Unsatisfactory performance stability, weakening ZnO photocatalytic efficiency and other issues, to achieve the effect of improving visible light response, good thermal and chemical stability, and inhibiting recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

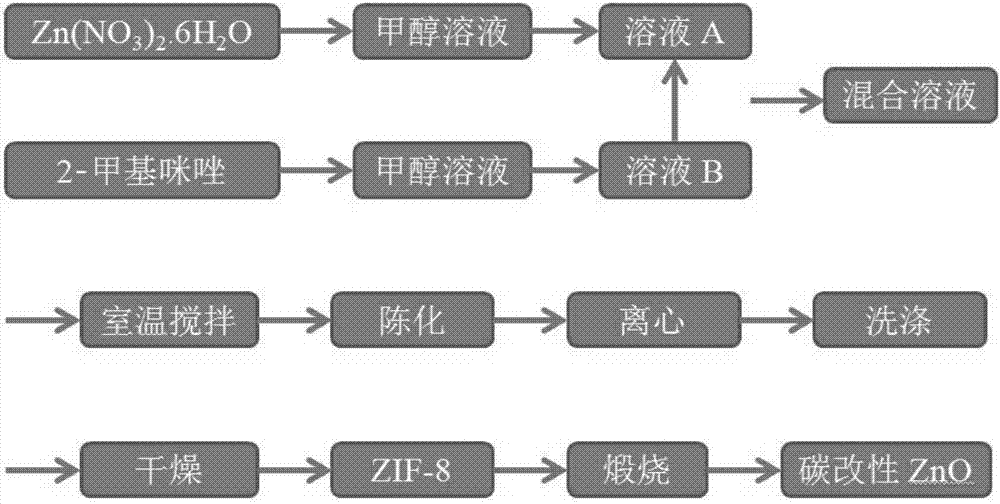

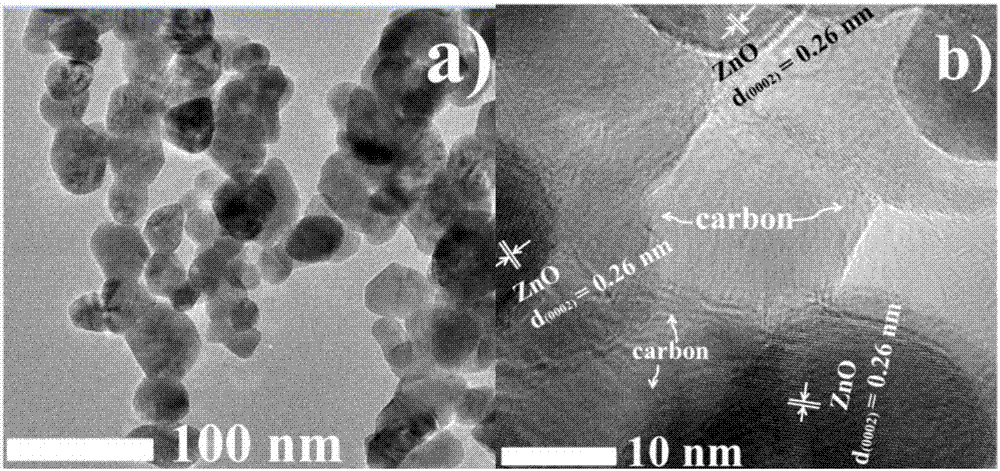

[0040] The methanol solution of 2-methylimidazole was added dropwise to the methanol solution of zinc nitrate hexahydrate, magnetically stirred for 1 hour at room temperature, and then allowed to stand for 24 hours. Finally, the obtained solution is centrifuged, washed with methanol and dried at a drying temperature of 80°C, and the obtained white solid is ground into ZIF-8 powder. The ZIF-8 powder was placed in an alumina crucible, covered with a lid and placed in a muffle furnace, heated to 500°C at a heating rate of 5°C per minute and kept at this temperature for 2 hours. The obtained powder is the porous carbon modified ZnO photocatalyst material. The TEM(a) and HRTEM(b) diagrams are as follows figure 2 Shown by figure 2 (a) It can be seen that ZnO is in the form of nanoparticles, with a particle size of several tens of nanometers (mostly not exceeding 50 nm). Because of the cubic sodalite structure of ZIF-8, metal ions are highly dispersed and separated by organic ligan...

Embodiment 2

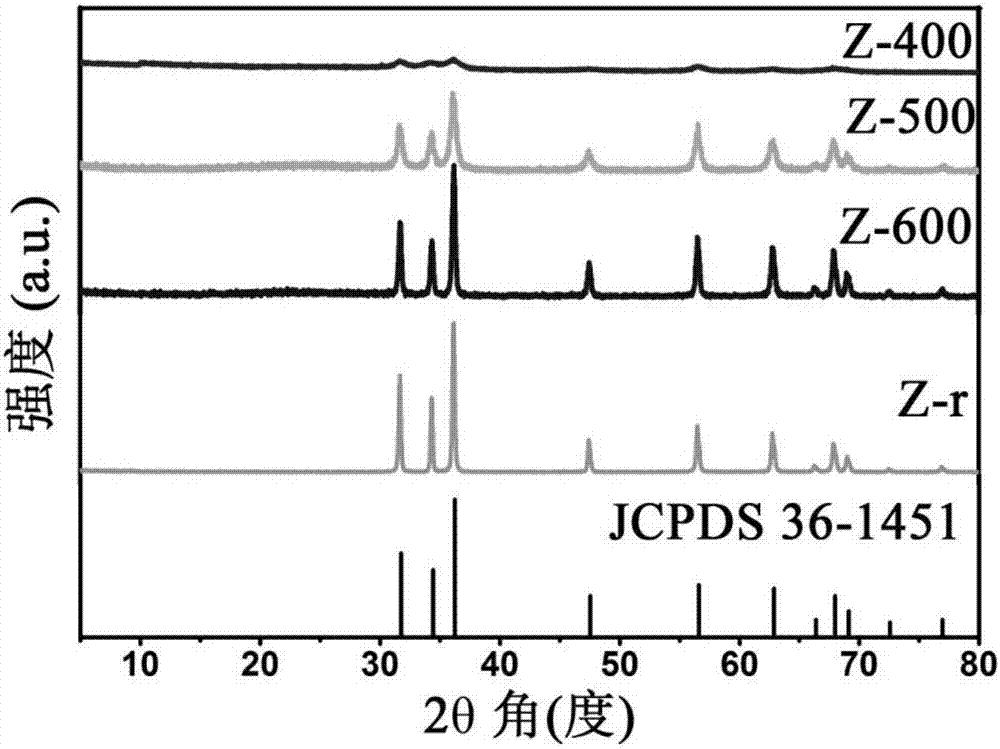

[0045] The methanol solution of 2-methylimidazole was added dropwise to the methanol solution of zinc nitrate tetrahydrate, magnetically stirred at room temperature for 1 hour, and then allowed to stand for 24 hours. Finally, the obtained solution is centrifuged, washed with methanol and dried at a drying temperature of 80° C., and the obtained white solid is ground into ZIF-8 powder. The ZIF-8 powder was placed in an alumina crucible, covered with a lid and placed in a muffle furnace, heated to 400°C at a heating rate of 5°C per minute and kept at this temperature for 2 hours. The obtained powder is the porous carbon modified ZnO photocatalyst material. Refer to Example 1 for XRD, UV-Vis absorption, specific surface area, pore size and CO 2 Adsorption test, see the results separately image 3 , Figure 7 , Figure 8 with Picture 9 .

Embodiment 3

[0047] The methanol solution of 2-methylimidazole was added dropwise to the methanol solution of zinc nitrate hexahydrate, magnetically stirred for 1 hour at room temperature, and then allowed to stand for 24 hours. Finally, the obtained solution is centrifuged, washed with methanol and dried at a drying temperature of 80°C, and the obtained white solid is ground into ZIF-8 powder. The ZIF-8 powder was placed in an alumina crucible, covered with a lid, and placed in a muffle furnace, heated to 600°C at a heating rate of 5°C per minute and kept at this temperature for 2 hours. The obtained powder is the porous carbon modified ZnO photocatalyst material. Refer to Example 1 for XRD, UV-Vis absorption, specific surface area, pore size and CO 2 Adsorption test, see the results separately image 3 , Figure 7 , Figure 8 with Picture 9 And table 1.

[0048] Table 1

[0049]

[0050]

[0051] PV: pore volume; APS: average pore size

[0052] The above results comprehensively show that ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com