Desulfurization wastewater treatment method and system

A technology for desulfurization wastewater and treatment methods, which is applied in the direction of gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problems of affecting evaporation effect, increasing coal consumption, and high construction investment, so as to improve recycling. High efficiency, low operation and maintenance costs, and convenient system connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

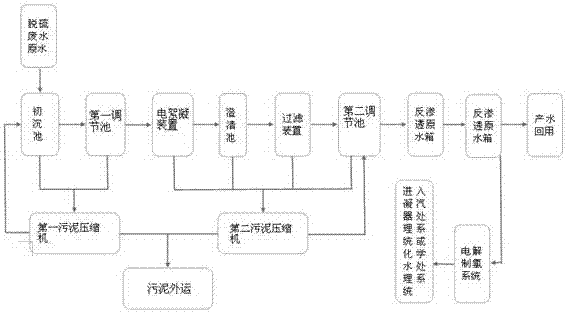

[0050] The technical scheme of a desulfurization wastewater treatment method and system of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0051] A kind of desulfurization waste water treatment method, is divided into following several steps:

[0052] Step S1, the desulfurization wastewater is left standing for clarification to produce a supernatant;

[0053] Step S2, adjusting the pH value of the desulfurization wastewater treated in step S1 for the first time, specifically, adding an alkaline solution to the desulfurization wastewater treated in step S1 and mixing evenly so that the mixed wastewater solution is alkaline;

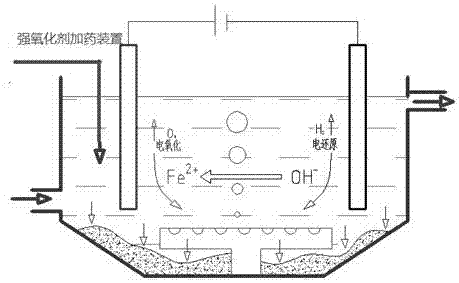

[0054] Step S3: Perform electrocoagulation softening treatment on the desulfurization wastewater treated in step S2, remove COD through the electro-Fenton reaction of an externally strengthened oxidant, and remove suspended solids and heavy metals in the water through self-fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com